Monitoring system of special mixer for full biodegradation of garbage and method thereof

A monitoring system and biodegradation technology, applied in the control/regulation system, non-electric variable control, simultaneous control of multiple variables, etc., can solve the problem that the optimal timing and total amount of feeding should not be controlled, the normal degradation efficiency will decline, and it cannot be completely Degradation and other problems, to avoid blocking and jamming, ensure the best environment, and avoid damage to the bacterial material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in combination with specific embodiments.

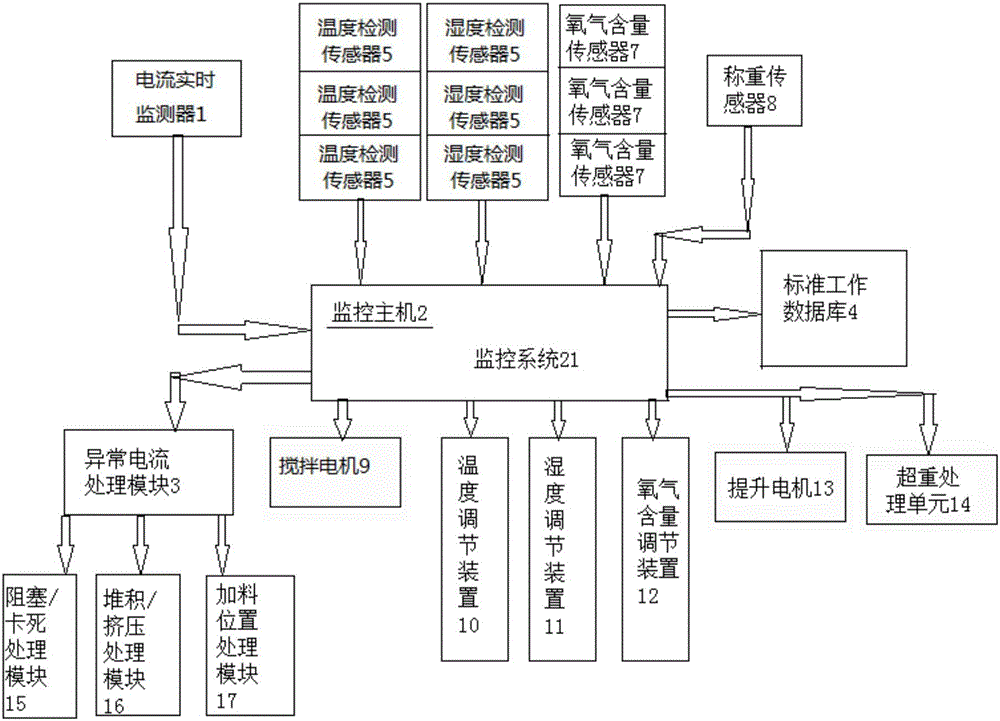

[0027] see figure 1 Shown is a structural frame diagram of an embodiment of the present application. In this embodiment, the monitoring system for a dedicated mixer for complete biodegradation of garbage includes a main body of the mixer, a stirring paddle arranged in the main body of the mixer, a stirring motor for controlling the paddle, a feeding hopper and a The lifting motor connected to the material hopper also includes: a current real-time monitor 1, a monitoring host 2, an abnormal current processing module 3, a standard working database 4, 3 temperature detection sensors, 5, 3 humidity detection sensors 6 and at least Components such as an oxygen content sensor 7 and a load cell 8.

[0028]The real-time current monitor 1 is installed on the stirring motor 9 , and the real-time current monitor 1 is used to detect the current data of the stirring motor in real ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com