A kind of high-voltage lithium nickel manganese oxide/graphite lithium ion battery and its manufacturing method

A lithium ion battery, lithium nickel manganese oxide technology, applied in the field of high-voltage lithium nickel manganate/graphite lithium ion battery production, can solve the problems of capacity decay, no use value, etc., to increase the capacity value and improve the specific capacity of the battery Play and optimize the effect of the ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

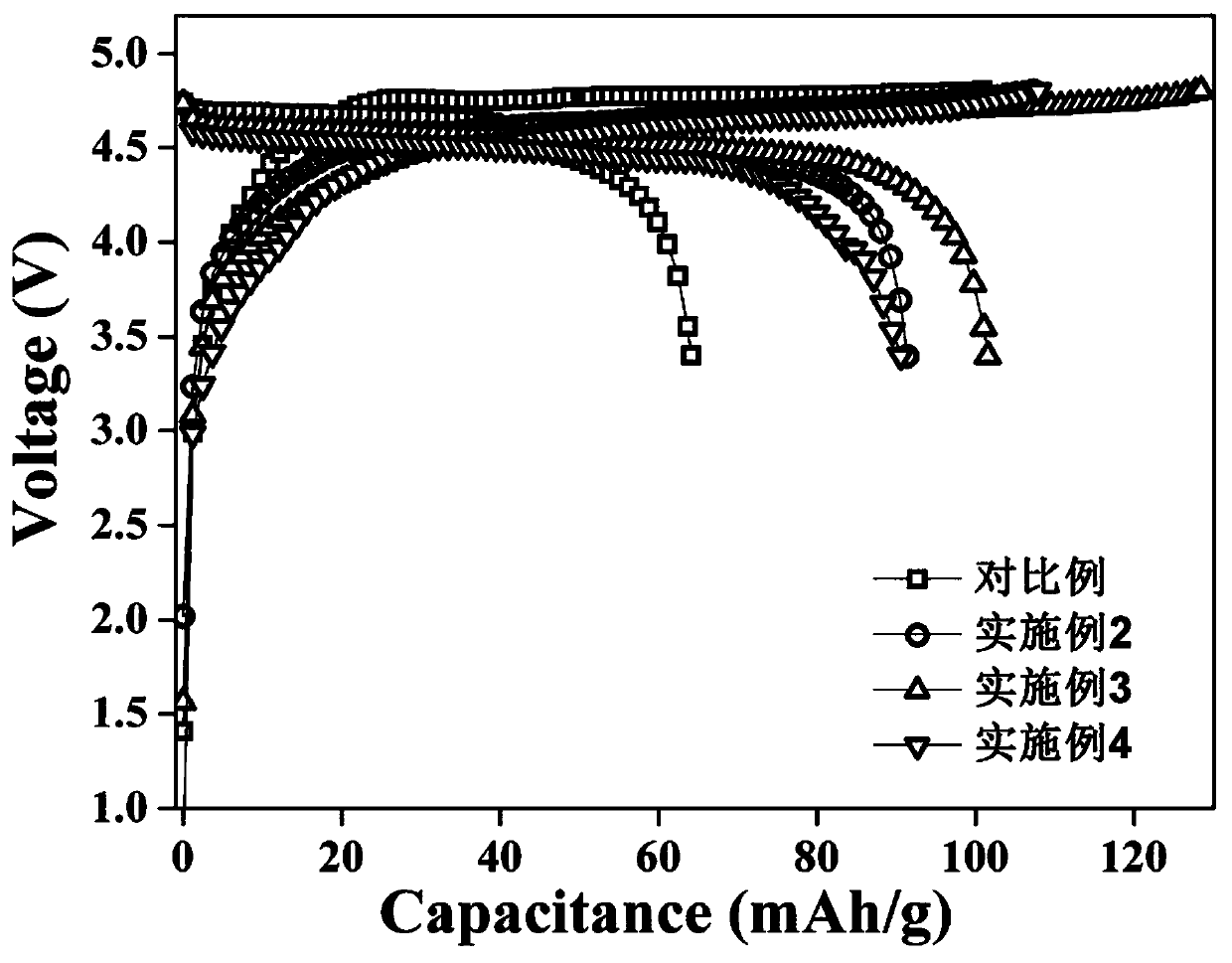

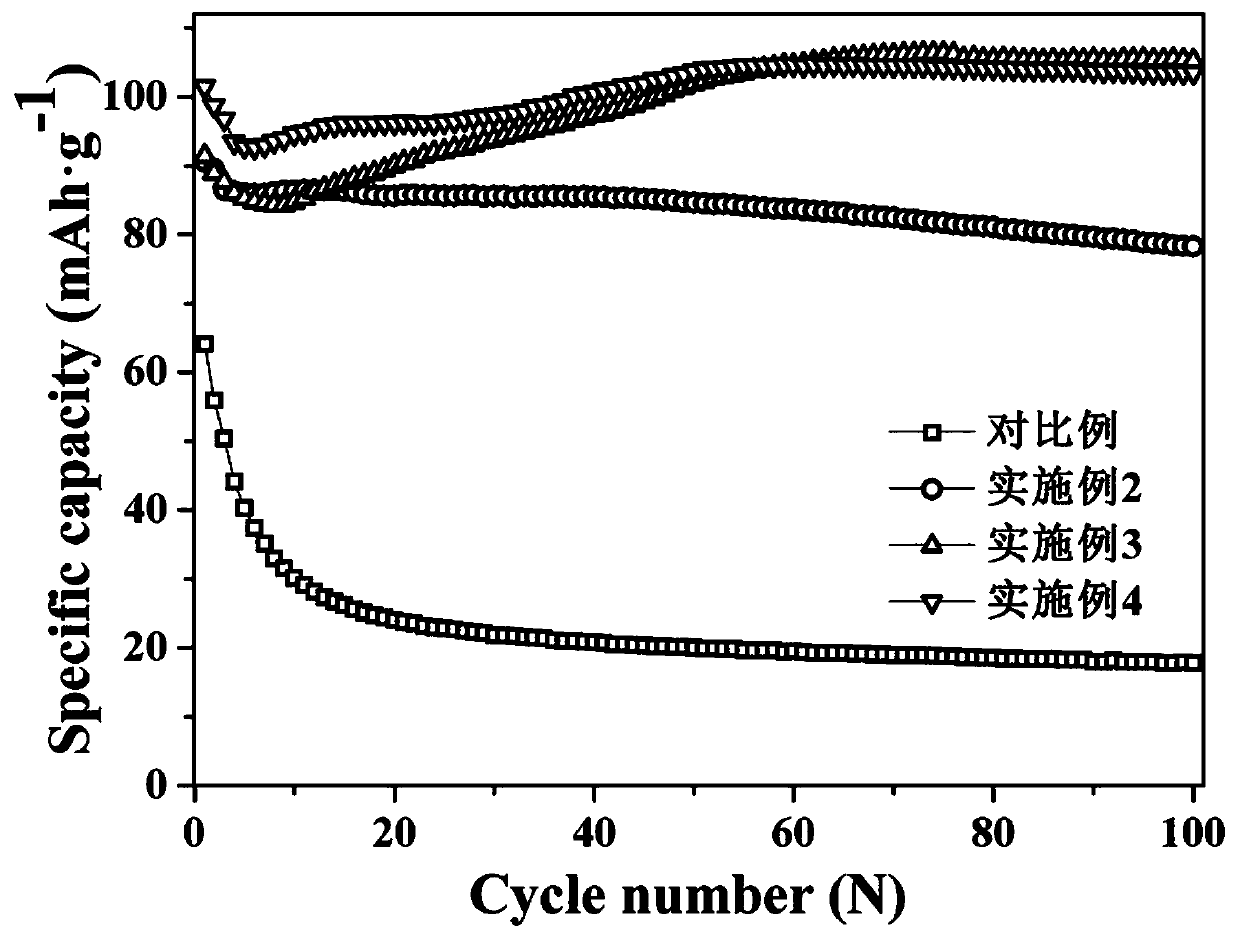

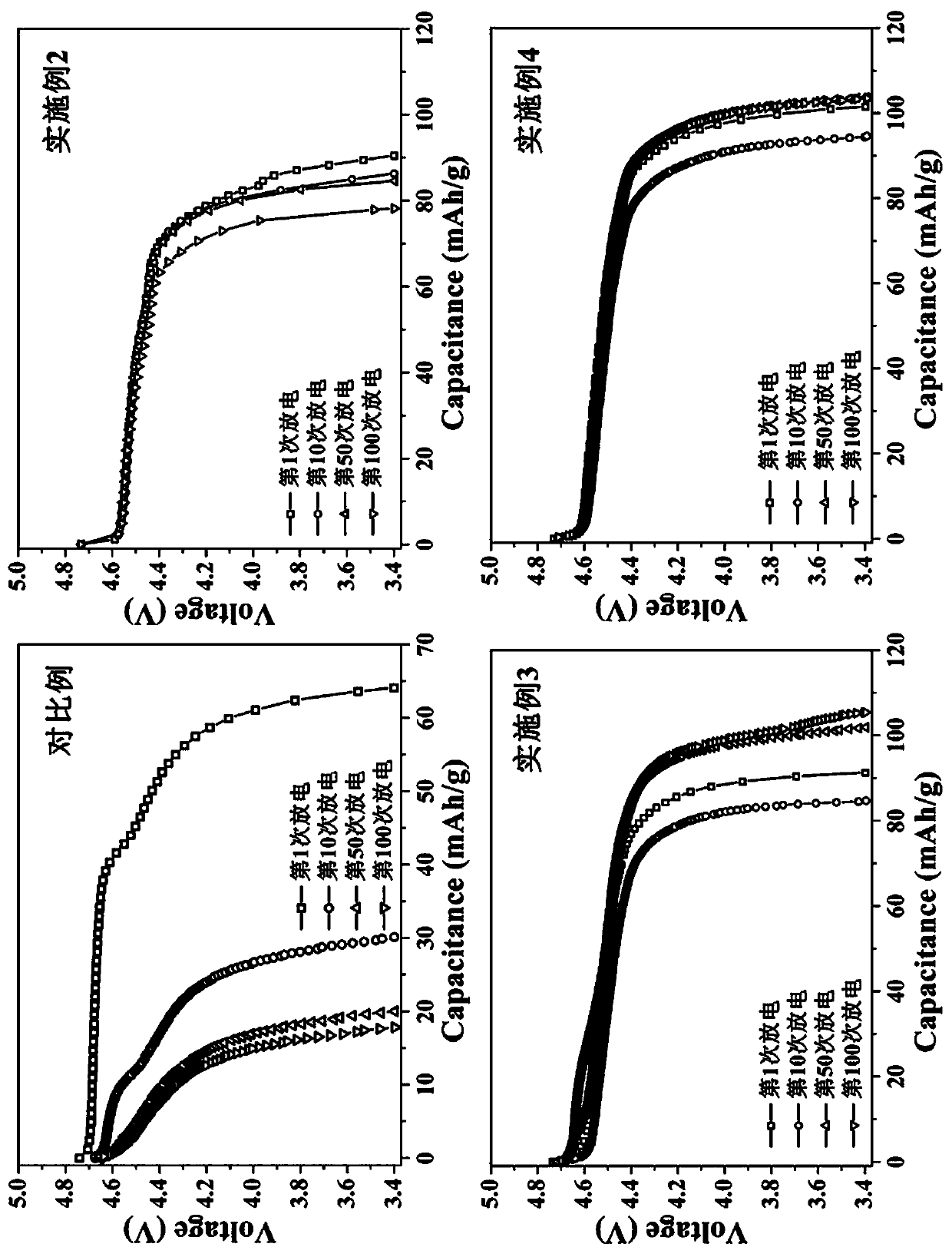

[0046] Example 1 (comparative example)

[0047] A method for manufacturing a lithium ion battery includes the following steps:

[0048] (1) Preparation of negative electrode pieces: According to the conventional negative electrode slurry preparation method, the negative electrode material, conductive agent, and binder are mixed and dissolved in deionized water at a ratio of 90:2.5:2.5, and the negative electrode slurry is adjusted after sufficient stirring. The viscosity is 3500mPa.s and the solid content is 32%. After baking and filming, the thickness is 0.166mm, and the surface density of the negative electrode is 105g / m. 2 The conventional negative pole piece;

[0049] (2) Preparation of positive pole pieces: According to the conventional method of preparing negative pole pieces, mix the positive electrode LNMO material, the binder PVDF, and the conductive agent AB, and then add them to the organic solvent NMP to prepare the positive electrode slurry to ensure the battery capacit...

Embodiment 2

[0053] A manufacturing method of a high-voltage lithium nickel manganate / graphite lithium ion battery includes the following steps:

[0054] (1) Preparation of negative electrode slurry: the method is the same as in Example 1, and the negative electrode slurry is prepared;

[0055] (2) Preparation of the negative electrode sheet containing the initial state SEI film: After the negative electrode slurry is fully mixed and uniform, 3wt% of organic acid grease is added to prepare the negative electrode slurry containing the initial state SEI film, after baking and filming process Prepare the negative pole piece containing the initial state SEI film, the thickness is 0.166mm, and the surface density of the negative electrode is 105g / m. 2 ;

[0056] (3) Preparation of the positive pole piece: According to the conventional method of preparing the negative pole piece, mix the positive electrode LNMO material, the binder PVDF, and the conductive agent AB, and then add it to the organic solve...

Embodiment 3

[0060] A manufacturing method of a high-voltage lithium nickel manganate / graphite lithium ion battery includes the following steps:

[0061] (1) The previous steps are the same as in Example 2, and the negative electrode piece containing the initial state SEI film is prepared;

[0062] (2) Preparation of 2wt% LTO coated LNMO positive pole piece:

[0063] First, prepare 2wt% LTO coated LNMO composite cathode material:

[0064] Take 1.6g of LNMO cathode material and dissolve it in deionized water, add 0.02g of surfactant F127 and mix to obtain A solution;

[0065] Weigh 0.096g titanium sulfate (Ti(SO 4 ) 2 ) Dissolve in 50ml of deionized water, add urea as a precipitant, and formulate a 0.5mol / l aqueous solution of titanium sulfate according to the molar ratio of titanium sulfate / urea of 1:2 to obtain liquid B. The amount of titanium sulfate must be TiO 2 2wt% of the mass of LNMO;

[0066] Slowly add liquid B to the continuously stirred liquid A. After stirring for 5 hours, transfer it t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com