Modified gas filter suitable for instrument systems

A technology of gas filter and instrumentation system, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of high temperature resistance of the filter, and achieve enhanced filtering effect, good wear resistance, and good scalability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

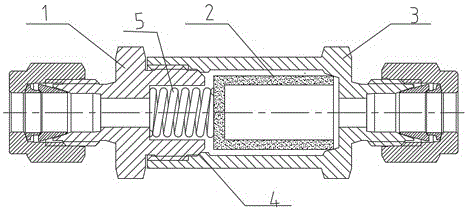

[0021] Such as figure 1 As shown, an improved gas filter suitable for an instrument system of the present invention includes an inlet valve body 1, which is radially symmetrical with respect to the air flow direction, and the inlet valve body 1 and the outlet valve body 3 form a cavity. In the cavity, according to the direction of air flow, there are spring 5 and filter element 2 in sequence. One end of spring 5 is on the filter element 2, and the other end of spring 5 is on the inlet valve body 1. There is a vent inside the inlet valve body 1. The diameter of the vent is smaller than the diameter of the spring 5, the inlet valve body 1 and the outlet valve body 3 are squeezed against each other, and the hard sealing surface 4 is formed through interference fit, the minimum clearance of the hard sealing surface 4 is zero, and the filter element 2 is located on the outlet valve body 3 Inside, the spring 5 is in a compressed state and is made of rust-free steel material. The spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com