A high-uniformity laser light guide plate processing method and device

A processing method and laser processing technology, which are applied in metal processing, laser welding equipment, metal processing equipment, etc., can solve the problems of poor uniformity of luminous brightness and complicated process of light guide plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

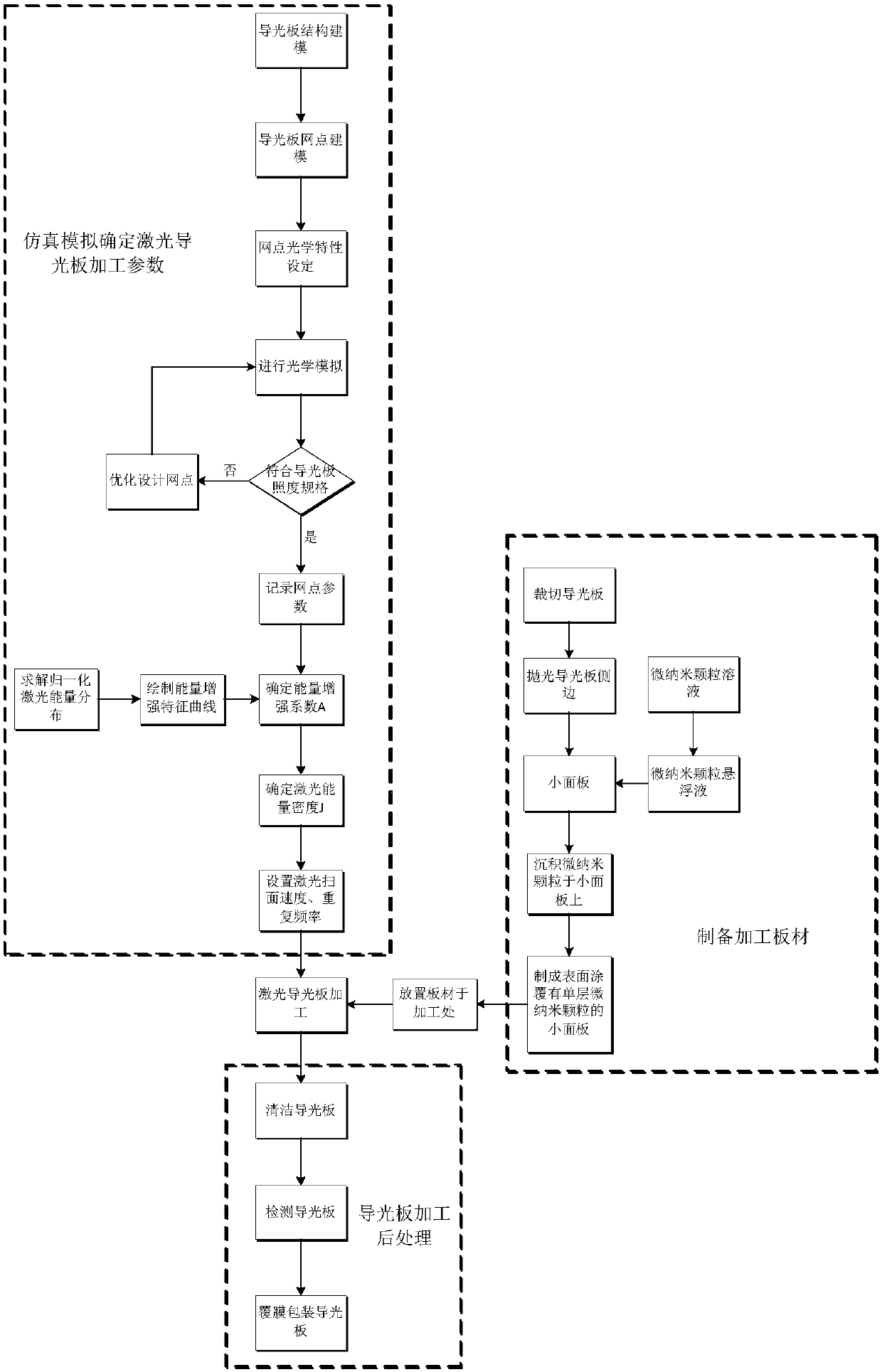

[0081] according to figure 1 Shown processing step has following embodiment:

[0082] The laser for processing is λ=1064nm, the beam diameter Φ=50μm, and the pulse width is 10ns.

[0083] Polymethyl methacrylate PMMA was selected as the processing material of the laser light guide plate, and the PMMA was cut by mechanical cutting, and the surface and sides of the panel were flame-polished, and prepared into small panels to be processed before use.

[0084] Select micronanoparticles as SiO 2 , diameter d=2μm, sonicate the solution of micro-nanoparticles for 10min to obtain SiO 2 The micro-nanoparticle suspension is ready for use.

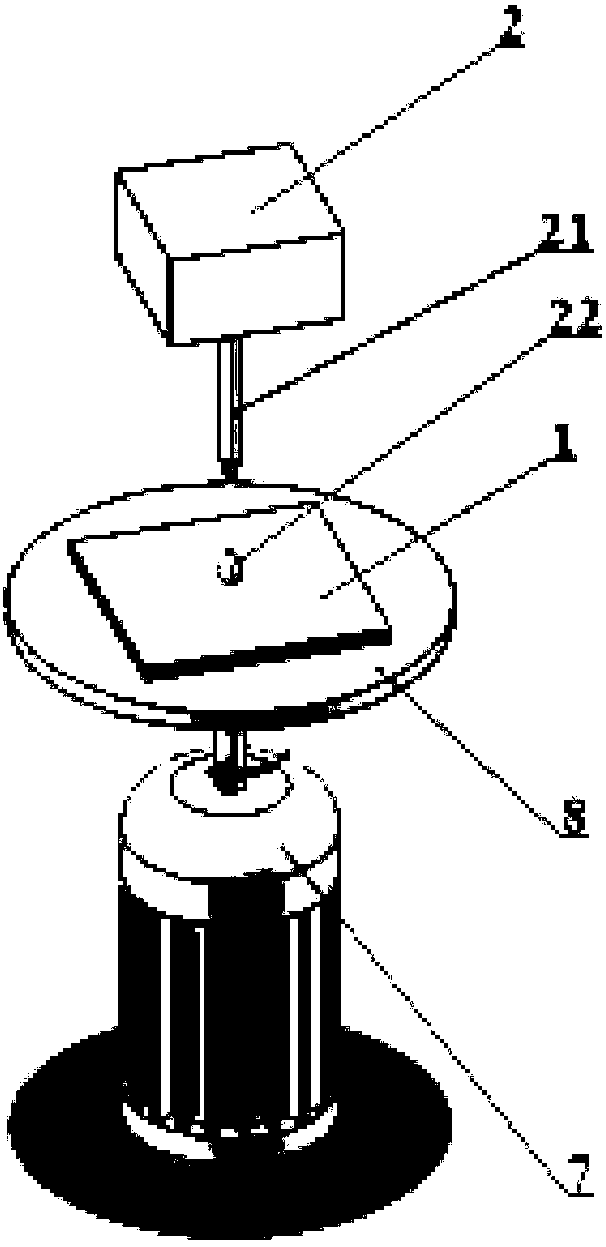

[0085] Place the small panel to be processed on the base 8 of the spin coating device of the present invention, drop SiO on the surface of the small panel to be processed 2 Suspension of micro-nano particles, start the device, set the speed N 1 =200r / min, duration T 1 =25s; after T 1 After that, set the speed N 2 =1000r / min, duration T 2 =35...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com