Method for recycling waste PET and producing environment-friendly type plastic shopping bags

An environmentally-friendly technology for shopping bags, which is applied in the production process of environmentally-friendly plastic shopping bags after recycling waste PET, can solve the problems of product inhomogeneity and insufficient overall strength, and achieve the effect of strengthening quality, better effect and balanced quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

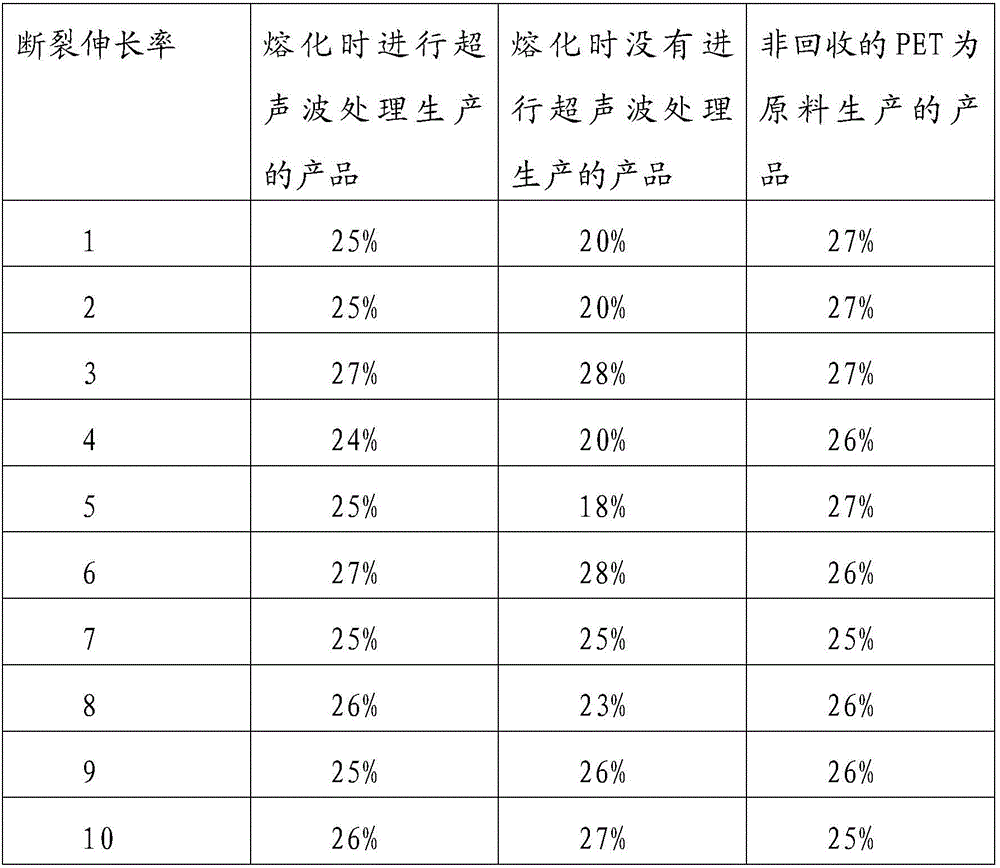

Examples

Embodiment 1

[0072] (1) Recycling waste plastic (PET):

[0073] Clean and crush the waste PET, clean the waste PET products, separate and detect the raw materials that meet the requirements, cut them into small pieces or strips, and then crush them into smaller pieces. The crushed pieces are sent to the dehumidifier Dryer for drying.

[0074] (2) Drawing:

[0075] The dried raw materials are blended with color masterbatch and flame retardant raw materials, heated and melted by heat medium, ultrasonically treated during melting, filtered after stirring, adjusted die temperature, passed through extruder substrate, cooled after extruding, Then cut into strips, then heated by the extension plate heater, then stretched longitudinally by the extension plate to form filaments, and then shaped by the shaping heater, cooled to normal temperature after shaping, passed through the speed-recycling roller, and then rolled by the winding machine After receiving the line, it can be packaged after passi...

Embodiment 2

[0121] In step (2) wire drawing, the parameters used are: the frequency of the ultrasonic waves is 5 MHz. The drying temperature should be 50°C for 30 minutes; extrude a substrate with a thickness of 0.5mm; the cooling temperature should be 20°C; use 80-mesh steel mesh for the filter. All the other uniform embodiment 1 is the same.

Embodiment 3

[0123] In step (2) wire drawing, the parameters used are: the frequency of the ultrasonic waves is 1 MHz. The drying temperature should be 60°C for 40 minutes; extrude a substrate with a thickness of 1mm; the cooling temperature should be 35°C; use 80-mesh steel mesh for the filter. All the other uniform embodiment 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com