Method for production of a fuel gas from carbonaceous material

A carbonaceous material, gas technology, applied in the manufacture of combustible gas, combustible gas purification, hydrogen/syngas production, etc., can solve the problems of landfill occupied space, visual pollution, toxicity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Throughout the specification and claims, unless specifically stated otherwise, the pressure is approximately ambient, ie, approximately atmospheric pressure. If not specifically defined differently, any indicated boiling point and / or boiling point range is the boiling point or boiling point range at atmospheric pressure. % of any composition is by weight when referring to solids or liquids and by volume when referring to gases, if not otherwise specified.

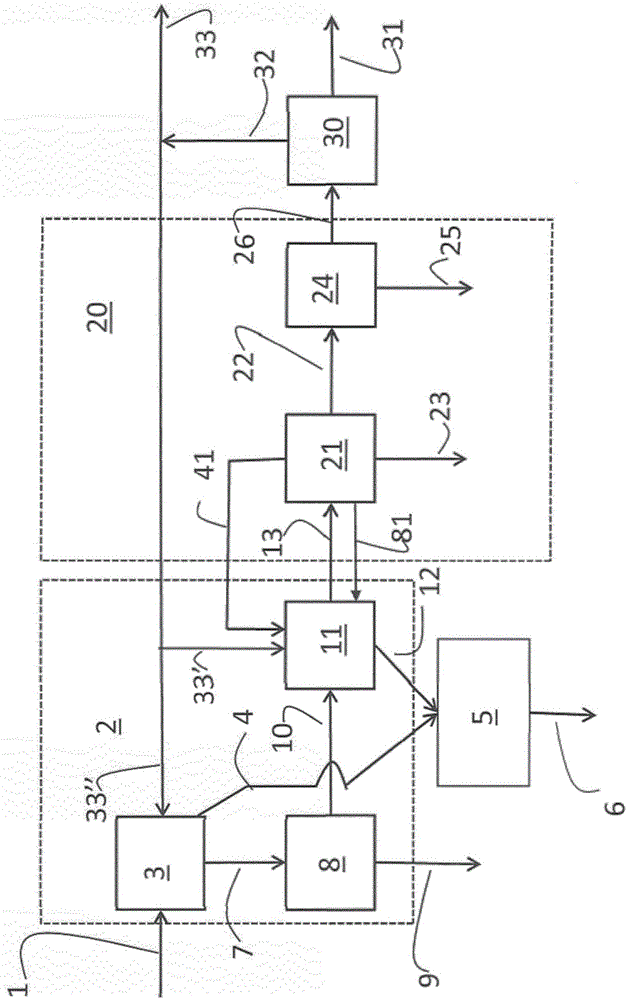

[0035] figure 1 is a schematic illustration of an embodiment of the invention in which influent is introduced via a waste line 1 into a waste pre-treatment area 2 .

[0036] The pretreatment zone of the illustrated embodiment comprises an autoclave treatment system 3 into which the MSW in line 1 is first introduced. Autoclaves suitable for this purpose are supplied, for example, by the AeroThermal Group (UK). The autoclave system preferably comprises a series of rotary autoclaves arranged in parallel, wherein the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com