Method for synthesizing tungsten-modified alumina mesoporous material through solvent-evaporation induced self-assembly and catalysis application thereof

A mesoporous material and self-assembly technology, which is applied in the field of mesoporous material modification and alumina mesoporous materials, can solve the problems of easy falling off, surface agglomeration of mesoporous materials, and large mass transfer resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve 1g of F127 in 10mL of absolute ethanol and 0.5mL of concentrated nitric acid, and stir until clear; dissolve 2.04g of aluminum isopropoxide in 10mL of absolute ethanol and 1mL of concentrated nitric acid, and stir until clear; press 1 of the above two solutions :1 mix, continue to stir until uniform; add silicotungstic acid (0.05mmol) ethanol solution dropwise according to the volume ratio of 3:40, continue to stir for 4h; transfer the solution into a petri dish and place 60 In the oven for 72h, and the gel obtained at 600 Low roasting for 4h, heating rate is 0.5 / min. The obtained mesoporous material is denoted as WO 3 (0.06) / Al 2 O 3 , Wherein the theoretical molar ratio of tungsten to aluminum is 0.06.

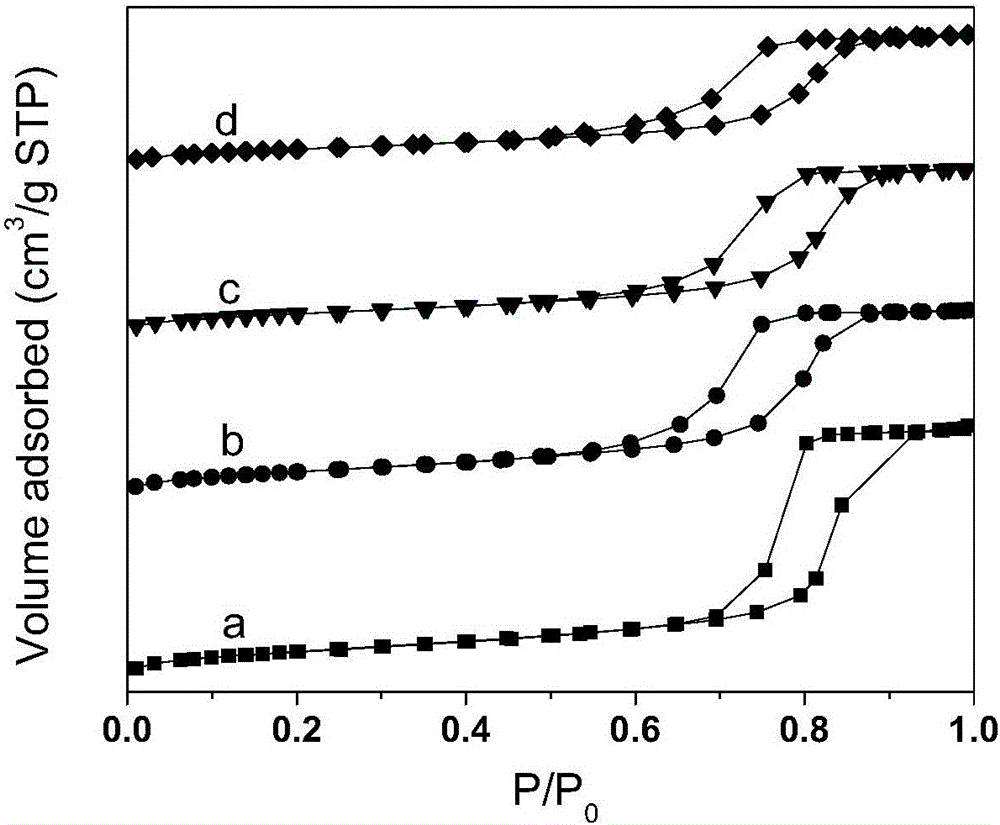

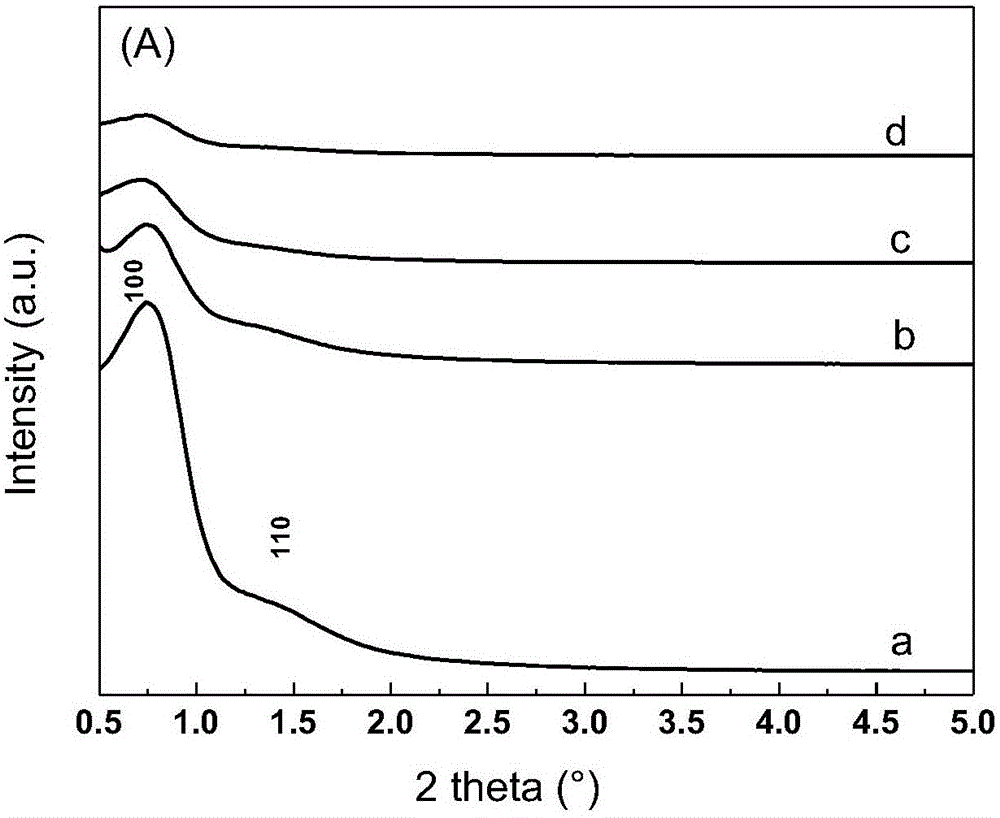

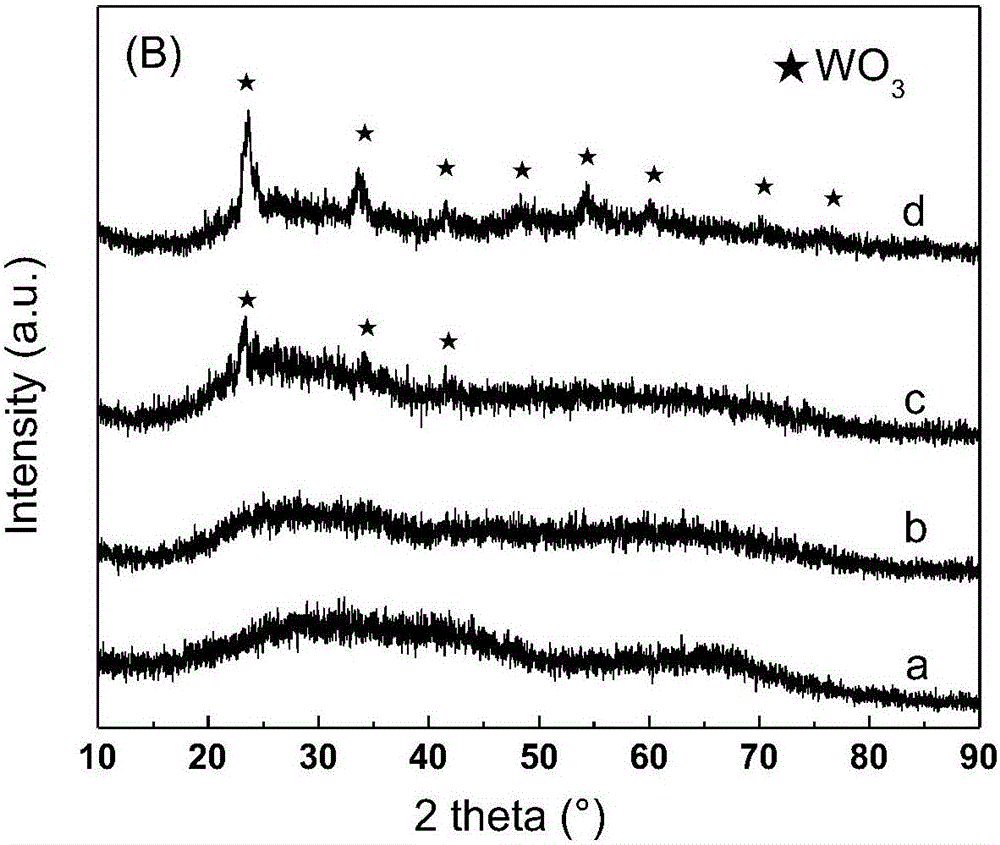

[0025] The tungsten-modified WO prepared in Example 1 was modified by using the Tristar 3000 automatic physical adsorption and desorption instrument from Micromeritics Company 3 / Al 2 O 3 The specific surface area, pore size distribution, pore volume and othe...

Embodiment 2

[0030] WO 3 (0.12) / Al 2 O 3 The preparation method is the same as in Example 1, changing the amount of silicotungstic acid in the silicotungstic acid ethanol solution to 0.1 mmol. The resulting solution is placed at 60 In the oven for 72 hours, the dried gel is at 600 Low roasting for 4h, heating rate is 0.5 / min. The obtained mesoporous materials are respectively denoted as WO 3 (0.12) / Al 2 O 3 , Wherein the theoretical molar ratio of tungsten to aluminum is 0.12.

Embodiment 3

[0032] WO 3 (0.24) / Al 2 O 3 The preparation method is the same as in Example 1, changing the amount of silicotungstic acid in the silicotungstic acid ethanol solution to 0.2 mmol. The resulting solution is placed at 60 In the oven for 72 hours, the dried gel is at 600 Low roasting for 4h, heating rate is 0.5 / min. The obtained mesoporous materials are respectively denoted as WO 3 (0.24) / Al 2 O 3 , Wherein the theoretical molar ratio of tungsten to aluminum is 0.24.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com