Catalyst for synthesizing 2,3,3,3-tetrafluoropropene, preparation method and purpose thereof

A tetrafluoropropene and catalyst technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of easy carbon deposition of catalysts, short catalyst life, and no industrialization prospects, etc., and achieve low cost , Long service life, reduce the effect of material circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

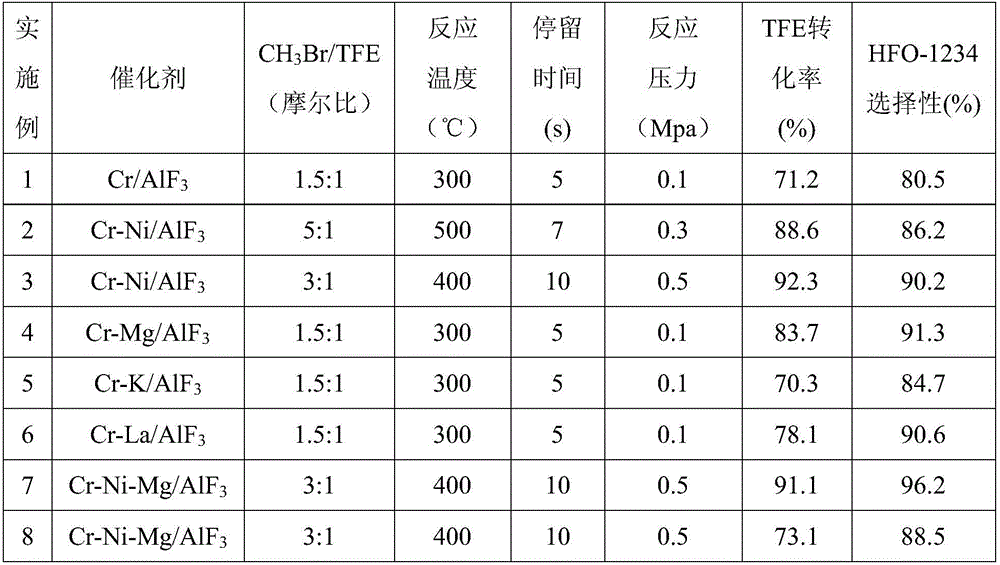

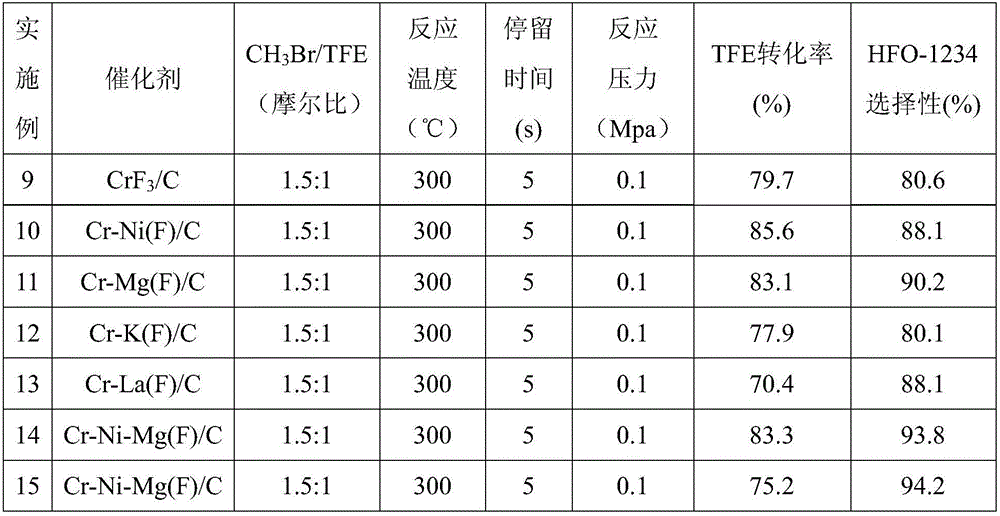

Examples

Embodiment 1

[0030] (1)Cr / AlF 3 Catalyst preparation

[0031] Cr(NO 3 ) 3 .6H 2 O is dissolved in water according to the amount of 5wt% of Cr loading, and is made into 30ml aqueous solution, and 50 grams of particle size is 3mm, and the specific surface area is 300m 2 / g of spherical γ-Al 2 o 3 As a carrier, the above aqueous solution is impregnated on the carrier with equal volume, and the immersion time is 12h. After impregnation, dry at 100°C for 12h. The dried catalyst was filled into a 316L stainless steel tubular reactor with an inner diameter of 26mm and a length of 60mm, and was roasted with nitrogen at 400°C for 4h, then cooled to 320°C for 8h with nitrogen, and then passed at 320°C The volume percentage of anhydrous hydrogen fluoride (AHF) is 1% mixed gas of anhydrous hydrogen fluoride and nitrogen (AHF / N 2 ) for fluorination activation for 2 hours, and then at a temperature of 350°C, the volume percentage of AHF is 5% AHF / N 2 Fluorination activation for 8 hours, and fin...

Embodiment 2

[0035] (1)Cr-Ni / AlF 3 Catalyst preparation

[0036] Cr(NO 3 ) 3 .6H 2 O and Ni(NO 3 ) 2 .6H 2O is dissolved in water according to the molar ratio of 2:1, and the total load of Cr-Ni is 5wt%. It is prepared into a 30ml aqueous solution, and 50 grams of the particle size is 1mm, and the specific surface area is 380m 2 / g of spherical γ-Al 2 o 3 As a carrier, the above-mentioned aqueous solution is impregnated on the carrier with equal volume, and the immersion time is 6h. After impregnation, dry at 120°C for 20h. The dried catalyst was filled into a 316L stainless steel tubular reactor with an inner diameter of 26mm and a length of 60mm, and was first roasted with nitrogen at 350°C for 6h, then lowered to 300°C for 10h with nitrogen, and then passed through at 300°C The volume percentage of anhydrous hydrogen fluoride (AHF) is 2% mixed gas of anhydrous hydrogen fluoride and nitrogen (AHF / N 2 ) for fluorination activation for 1 hour, and then feed AHF / N with a volume p...

Embodiment 3

[0040] (1)Cr-Ni / AlF 3 Catalyst preparation

[0041] Cr(NO 3 ) 3 .6H 2 O and Ni(NO 3 ) 2 .6H 2 O is dissolved in water according to the molar ratio of 2:1, and the amount of Cr-Ni total load 5wt% is prepared into a 30ml aqueous solution, and 50 grams of the particle size is 5mm, and the specific surface area is 320m 2 / g of spherical γ-Al 2 o 3 As a carrier, the above aqueous solution is impregnated on the carrier with equal volume, and the immersion time is 24h. After impregnation, dry at 150°C for 10h. The dried catalyst was filled into a 316L stainless steel tubular reactor with an inner diameter of 26mm and a length of 60mm, and was roasted with nitrogen at 450°C for 2h, then lowered to 250°C for 5h with nitrogen, and then passed through at 250°C The volume percentage of anhydrous hydrogen fluoride (AHF) is 3% mixed gas of anhydrous hydrogen fluoride and nitrogen (AHF / N 2 ) for fluorination activation for 3 hours, and then at a temperature of 400°C, AHF / N with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com