Automatic dispersing device for carbon nano tube conductive slurry

A technology of conductive paste and carbon nanotubes, applied in material resistance, grain treatment, etc., can solve the problems of volatile defoamer, uncontrollable amount of defoamer added, poor defoaming effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present application will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

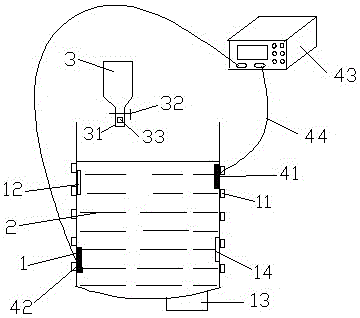

[0032] Such as figure 1 As shown, an automatic dispersing device for carbon nanotube conductive paste includes a ceramic grinding barrel 1, a circulating water pipe 11, a liquid level sensor 12, a controller 13, a temperature sensor 14, a carbon nanotube conductive paste 2, and a defoamer Storage tank 3, liquid outlet 31, solenoid valve 32, flow sensor 33, electrode a 41, electrode b 42, resistance meter 43, wire 44 and other main technical features.

[0033] An automatic dispersion device for carbon nanotube conductive slurry, comprising a ceramic grinding barrel, carbon nanotube conductive slurry, a defoamer storage tank and a dispersion effect tester.

[0034] There is a controller at the bottom of the ceramic grinding barrel, and a timer is built in the controller; serpentine circulating water pipes are evenly wound a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com