A mold for pressing metal rubber material

A technology of metal rubber and mould, which is applied in the direction of manufacturing tools, metal processing equipment, forming tools, etc., can solve problems such as jamming and no mention of jamming, so as to reduce the trouble of replacing molds, improve the phenomenon of jamming, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

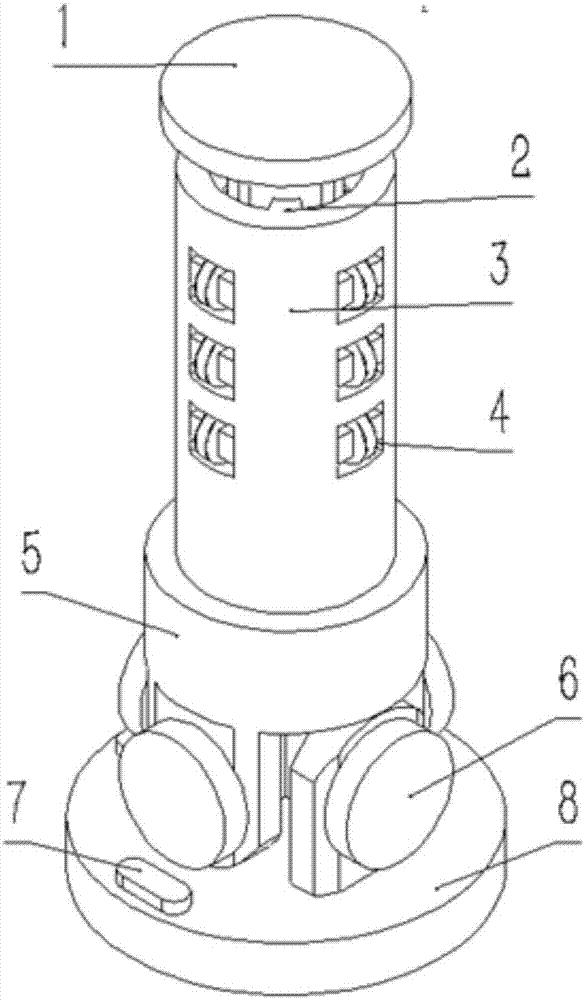

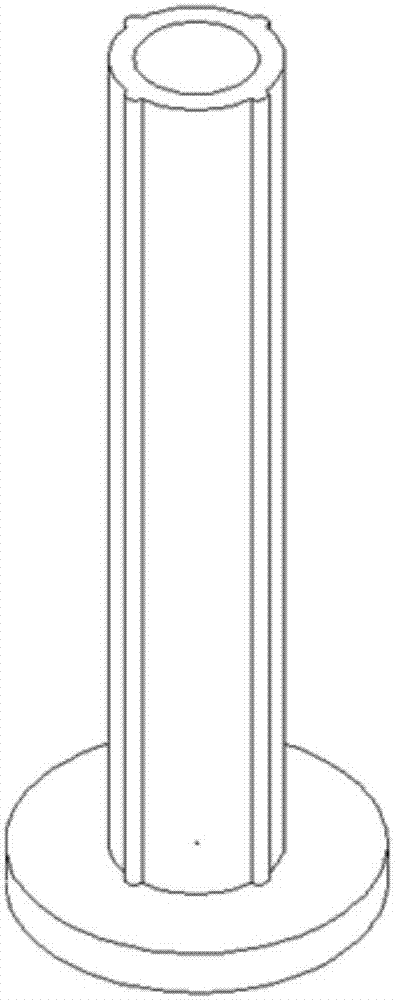

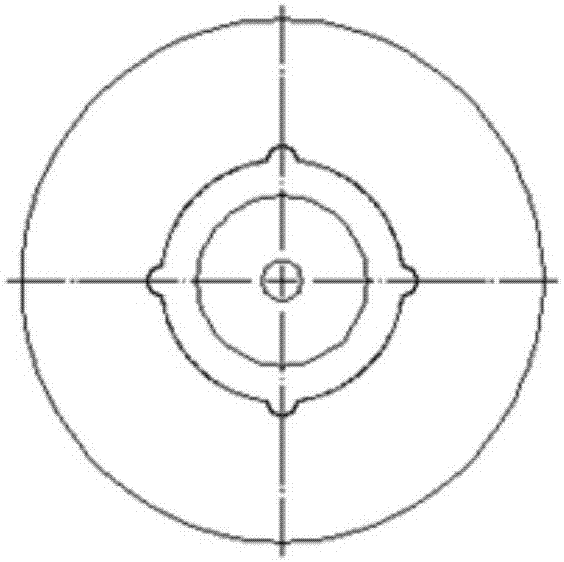

[0020] Example 1: Combining Figure 1 to Figure 6 , a new mold for pressing metal rubber materials of the present invention includes an upper pressing rod 1, a retractable metal sheet 2, a pressing rod guide shell 3, a U-shaped ball bearing 4, a punch base 5, a cross shaft 6, a bubble level 7, Guide base 8, metal rod 9. Wherein the upper pressing rod is inserted into the inside of the pressing rod guide shell, and the four protruding circular arcs cooperate with the U-shaped ball bearings. The boss on the punch base is inserted into the circular groove of the upper pressing rod, and at this time the pressing rod guide shell is inserted into the annular groove of the punch base.

[0021] That is the present invention comprises compression device and base two major parts. The compression device includes a pressing bar guide shell 3, a U-shaped ball bearing 4, a punch base 5 and an upper pressing bar 1. The base part includes a guide base 8 and a bubble level 7 . The ball bea...

Embodiment 2

[0024] Embodiment 2: Based on the above-mentioned embodiment, the present invention can also be: the bubble level is arranged on the guide base in the horizontal and vertical directions, that is, the bubble level is arranged on the base, and respectively arranged along the front, rear and left and right directions One. The bubble level on the guide base can keep the mold at a preliminary level when it is put into the compressor.

Embodiment 3

[0025] Embodiment 3: Based on the above embodiment, the present invention can also be: a length scale that can read the amount of compression is arranged on the long rod of the upper pressing tool, that is, the upper pressing rod is provided with a length scale, which can easily read the compression quantity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com