Bottleneck cold air pipe for bottle blowing machine

A cold air duct and bottle blowing machine technology, applied in applications, household appliances, household components, etc., can solve the problems of easy flashing of bottle mouth waste and high bottle mouth temperature, and achieve good cooling effect, smooth treatment surface and long service life strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

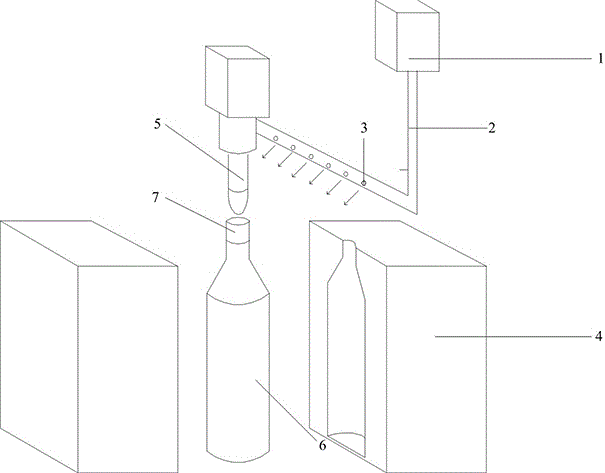

[0023] like figure 1 As shown, a bottle mouth cold air pipe for blow molding machine is installed on the SCJ65U blow molding machine for blowing laundry detergent bottles. The in-bottle cooling device 5 and the mold 4 also include a cold air pipe 2 located at 5 cm from the side of the in-bottle cooling device 5. At least one cold air port 3 is opened on the cold air pipe. One end of the cold air pipe is connected with the air cooler 1. The cold air pipe 2 is made of PVC. Pipe, pipe diameter 2cm, three cold air outlets 3 with a diameter of 2mm are opened on the cold air pipe 2, the distance between adjacent air outlets is 1.5cm, the interface between the air cooler 1 and the cold air pipe 2 has a cooling water inlet, and the bottle body 6 is in the mold When the 4 parts are processed and formed, the cooling device 5 in the bottle injects cooling gas from the bottle mouth to form the inner wall of the bottle, and the cold air pipe 2 cools the bottle mouth waste 7 at the same tim...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is that a cold air pipe 2 is installed at 15 cm from the side of the cooling device 5 in the bottle. The cold air pipe 2 is made of PP pipe with a pipe diameter of 8 cm. There are five cold air outlets with a diameter of 1.5 mm on the cold air pipe 2. 3. 95% of the finished products do not need to be flashed.

Embodiment 3

[0027] The difference between this embodiment and embodiment 2 is that a cold air pipe 2 is set at 40 cm from the side of the cooling device 5 in the bottle, the diameter of the cold air pipe 2 is 5 cm, and there are two cold air ports 3 on the cold air pipe 2. Perform flash processing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com