Composite plate having sandwiched structure and preparation method thereof

A sandwich structure and composite board technology, applied in the field of composite boards, can solve the problems of easy damage, poor compression resistance, and difficulty in achieving the best energy absorption per unit mass, and achieve the best energy absorption and good compression resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

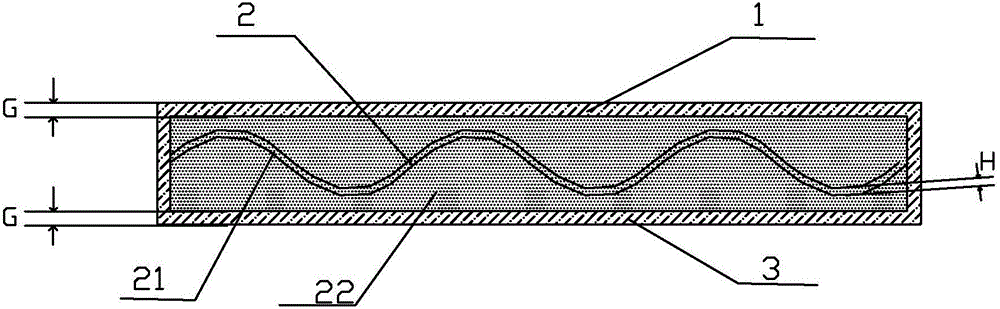

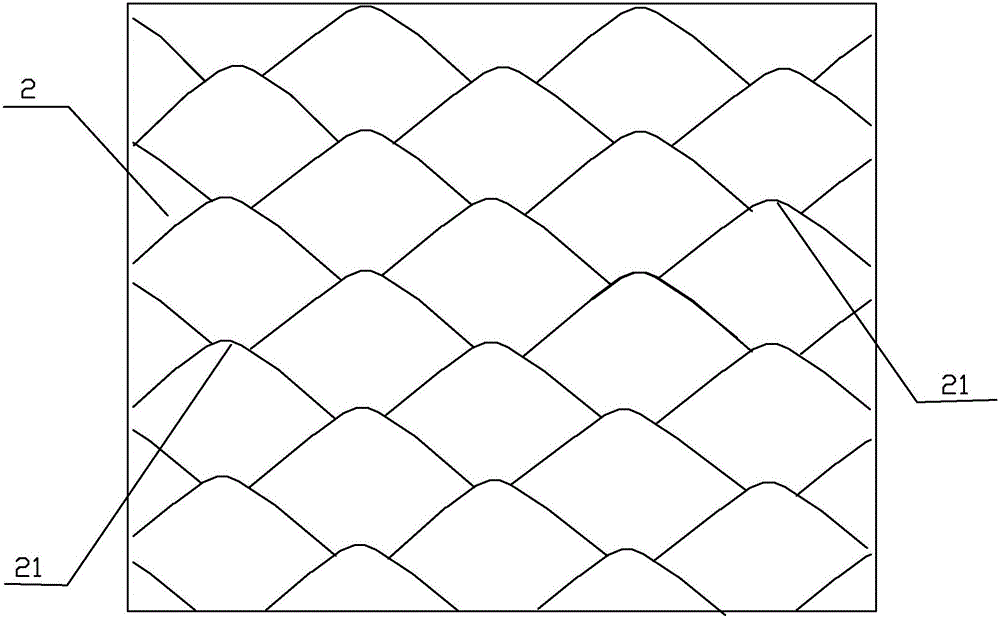

[0021] Please refer to figure 1 , a composite panel with a sandwich structure, the composite panel includes an upper panel 1, a lower panel 3 and a sandwich layer 2 between the upper panel 1 and the lower panel 3, the upper panel 1 and the lower panel 3 Prepared by glass fiber prepreg, the thickness G is 1.5mm, the sandwich layer 2 includes more than one spherical support device 21 and buffer 22 arranged in topological structure, and the buffer 22 is thermoplastic polyurethane Foam made of elastomeric rubber with a density of 1000 kg / m 3 . The thickness H of the spherical support device 21 is 3 mm, the buffer 22 is arranged between the upper panel 1 and the spherical support device 21 and between the spherical support device 21 and the lower panel 3, and the described spherical support device 21 is made of thermoplastic polyurethane and graphene, the thermoplastic polyurethane and graphene weight ratio is 25:1-50:1, and the number of layers of glass fiber prepreg is 15. The...

Embodiment 2

[0023] A preparation method of a composite panel with a sandwich structure, said preparation method comprising the steps of:

[0024] 7.1 After mixing the thermoplastic polyurethane rubber and graphene uniformly according to 1:1, put it into the mold used to prepare the spherical support device;

[0025] 7.2 Put the mold into a hot press for pressing at a temperature of 230°C and a pressure of 1.5MPa;

[0026] 7.3 Glue the upper and lower panels above and below the spherical support device;

[0027] 7.4 Inject PVC foam between the upper and lower panels.

[0028] Finally, the composite board with the spherical support device is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com