Energy-regenerative suspension for car and control method thereof

A suspension and accumulator technology, applied in the field of vehicle suspension research, can solve the problems of high manufacturing cost, inability to guarantee vehicle dynamics characteristics, and less energy recovered, so as to ensure reliability and improve energy recovery. Efficiency, loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

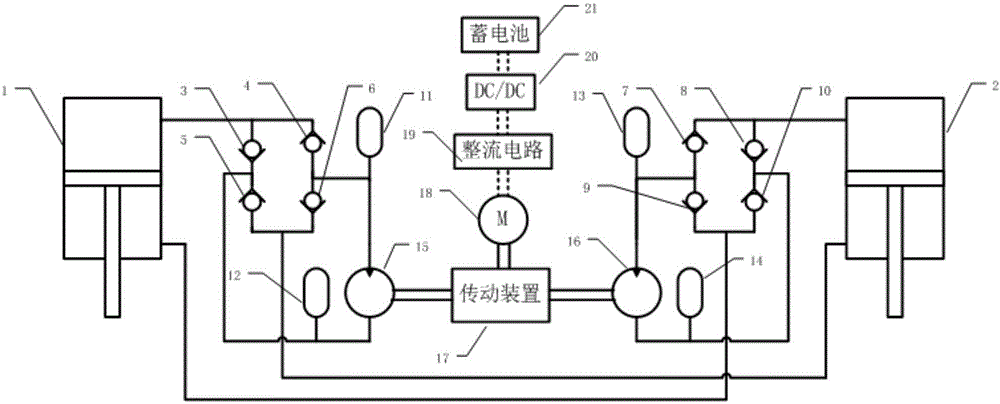

[0037] figure 1 Shown is an embodiment of the energy-feeding suspension for a vehicle of the present invention, which includes a hydraulic mechanism, a transmission device, a rotating electrical machine 18 and an electric storage mechanism.

[0038] The hydraulic mechanism includes hydraulic cylinder a1, hydraulic cylinder b2, one-way valve a3, one-way valve b4, one-way valve c5, one-way valve d6, one-way valve e7, one-way valve f8, one-way valve g9, one-way valve Valve h10, accumulator a11, accumulator b12, accumulator c13, accumulator d14, motor a15, and motor b16.

[0039]The oil inlet and the oil outlet of the one-way valve a3 are respectively connected with the oil inlet of the one-way valve c5 and the oil inlet of the one-way valve b4 through pipelines; the oil inlet and the outlet of the one-way valve d6 The oil port is respectively connected with the oil outlet of the one-way valve c5 and the one-way valve b4 through the pipeline; the oil inlet and the oil outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com