Preparation method for ceramic with bright-colored image

A technology of ceramic preparation and image, applied in the direction of copying/marking method, printing, etc., can solve the problems of high equipment cost, expensive plate making cost, obscure color, etc., and achieve good thermal shock resistance, good glaze smoothness, and color transition natural effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A method for preparing ceramics with vivid images, comprising the following steps:

[0036] 1. Image processing;

[0037] Selecting at least one monochromatic color in the image to develop a screen version;

[0038] In a preferred solution, the color development refers to visually prominent color blocks, larger-area color blocks and color blocks that require bright colors.

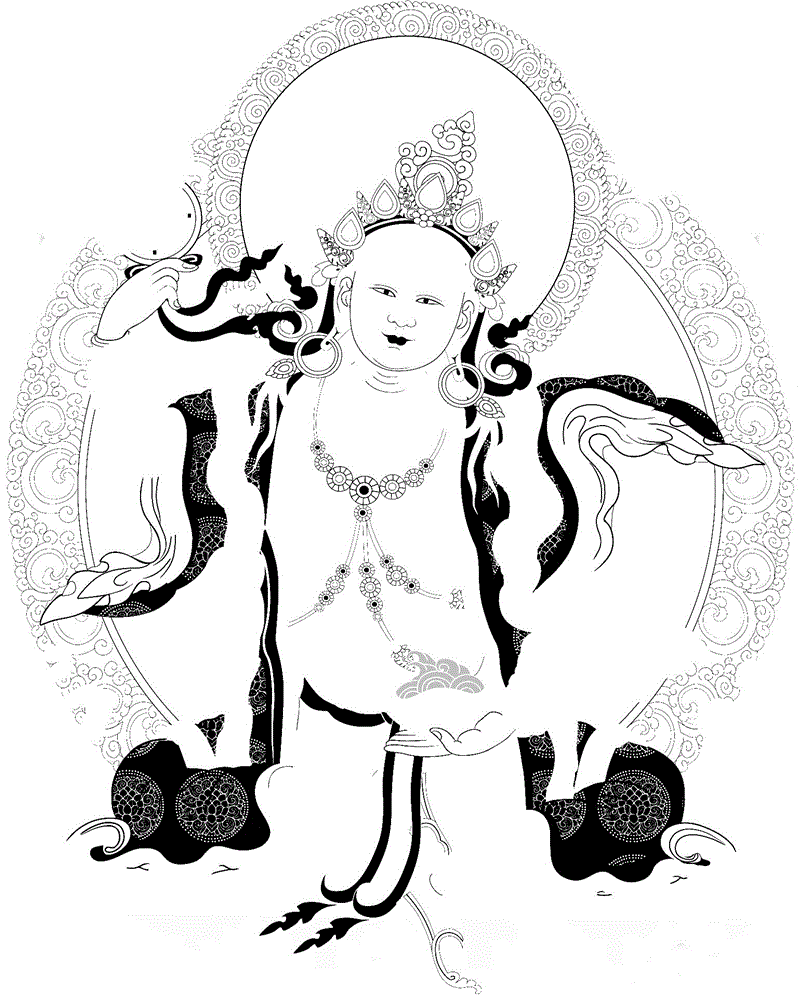

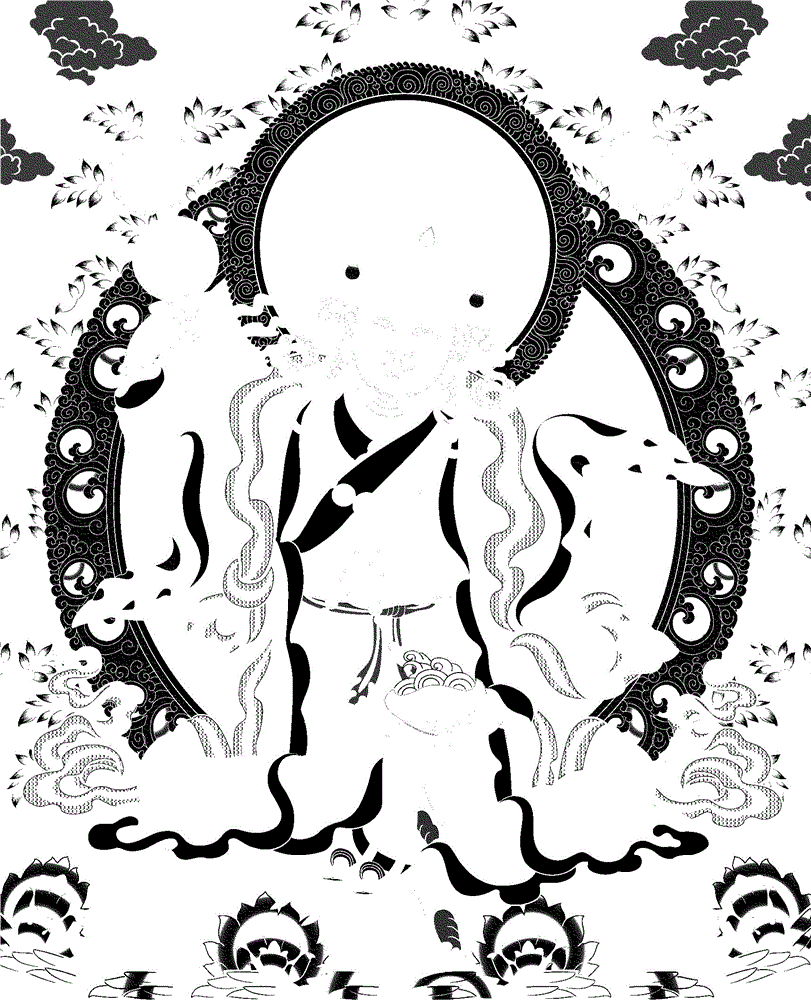

[0039] like Figure 1~4 in figure 1 Among them, the selected colors after comparison are red, gold and blue, among which red is a visually prominent color block, such as figure 2 As shown in , but in the colors formed by inkjet printing, it is difficult to ensure the bright effect of red and pink. After analysis, it may be due to the oxidation of the colorant during the high-temperature firing process, and the excessive particle size and content of the colorant in the inkjet ink. Low, difficult to develop color and other reasons. So choose red as one of the color rendering. Through screen pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com