Concrete produced from iron containing industrial tailings

A technology of industrial tailings and concrete, which is applied in the field of concrete, can solve the problems of polluting the environment of mining areas and surrounding areas, encroaching on large land, and forming safety issues, achieving considerable economic benefits, reducing environmental damage, and reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0029] Table 1 lists the proportion of each component of the concrete produced by utilizing iron-containing industrial tailings in the present invention;

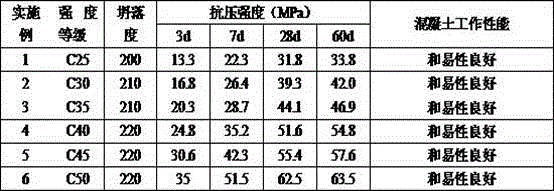

[0030] Table 2 lists the workability and compressive strength of a concrete produced from ferrous industrial tailings according to the present invention.

[0031] Table 1 The proportion of each component of a concrete produced from iron-containing industrial tailings in a single concrete (kg / m 3 )

[0032] Example

water-binder ratio

tailings gravel

Tailings sand making

Admixture

water

Concrete specific gravity

1

C25

0.51

247

925

925

53

53

7.1

180

2390

2

C30

0.45

280

948

874

60

60

8.0

180

2410

3

C35

0.4

333

957

814

54

63

9.0

180

2410

4

C40

0.37

370

971

763

58

58

10.2

180

2410

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com