In-situ-formed-fiber-reinforced thermoplastic elastomer film material and preparation method thereof

A thermoplastic elastomer and thermoplastic enhancement technology, which is applied in the field of in-situ fiber-forming reinforced thermoplastic elastomer film material and its preparation field, can solve the problem that the heat resistance, strength and modulus are difficult to meet requirements and affect the performance of thermoplastic elastomer film products. , The filler is difficult to disperse evenly in the elastomer, etc., to achieve the effect of controllable and stable product performance, easy industrial production, and controllable fiber size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 of the present invention: PLA in-situ fiber-forming reinforced POE thermoplastic elastomer film material, calculated in parts by weight, including 80 parts of POE, 20 parts of PLA, 2 parts of POE-GMA, 0.14 parts of antioxidant 1010 and 0.42 parts Auxiliary antioxidant DLTP.

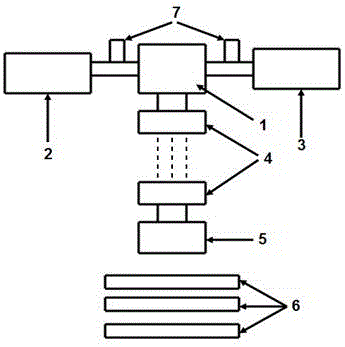

[0019] The preparation method of PLA in-situ fiber-forming reinforced POE thermoplastic elastomer film material is to dry PLA at a temperature of 80°C for 6-9 hours, and dry POE-GMA at a temperature of 60°C for 8-10 hours. , PLA, POE-GMA, antioxidant 1010 and DLTP are mixed evenly, and then the mixture is added to the twin-screw extruder on both sides of the polymer micro-nano lamination co-extrusion device for extrusion and traction to obtain PLA in-situ synthesis. Fiber-reinforced POE thermoplastic elastomer film material, the film thickness is 0.5mm, sample preparation according to the requirements of GB / T17037-1997, and then test the tensile properties according to the requirements...

Embodiment 2

[0020] Embodiment 2 of the present invention: Nylon 6 in-situ fiber-forming reinforced POE thermoplastic elastomer film material, calculated in parts by weight, includes 85 parts of POE, 15 parts of nylon 6, 3.5 parts of POE-GMA, 0.26 parts of antioxidant 1010 and 0.26 parts Antioxidant 168.

[0021] A method for preparing nylon 6 in-situ fiber-forming reinforced POE thermoplastic elastomer film material, drying nylon 6 at a temperature of 90°C for 8-10 hours, drying POE-GMA at a temperature of 60°C for 8-10 hours, according to the above-mentioned parts by weight, After mixing POE, nylon 6, POE-GMA, antioxidant 1010 and antioxidant 168 evenly, the mixture is added to the twin-screw extruder on both sides of the polymer micro-nano lamination co-extrusion device for extrusion and traction , to obtain nylon 6 in-situ fiber-forming reinforced POE thermoplastic elastomer film material, the film thickness is 0.4mm, sample preparation is carried out according to the requirements of G...

Embodiment 3

[0022] Embodiment 3 of the present invention: nylon 6 in-situ fiber-forming reinforced POE thermoplastic elastomer film material, calculated in parts by weight, including 85 parts of POE, 15 parts of nylon 6, 3.5 parts of POE-GMA, 0.26 parts of antioxidant 1010 and 0.26 parts Antioxidant 168.

[0023] A method for preparing nylon 6 in-situ fiber-forming reinforced POE thermoplastic elastomer film material, drying nylon 6 at a temperature of 90°C for 8-10 hours, drying POE-GMA at a temperature of 60°C for 8-10 hours, according to the above-mentioned parts by weight, Mix POE, nylon 6, POE-GMA, antioxidant 1010 and antioxidant 168 uniformly to obtain a compound; add the compound to a twin-screw extruder for extrusion and granulation to obtain a premix; The premix is added to the double-sided single-screw extruder in the polymer micro-nano laminated co-extrusion device described in the CN103059387A patent for extrusion and traction to obtain nylon 6 in-situ fiber-forming reinfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com