Benzoin spice and preparation method thereof

A technology of benzoin and benzoin resin, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of low yield of benzoin extract, viscous benzoin extract, and easy sticking in the container, so as to achieve low cost and solve the problem of fragrance Not outstanding, solve the effect that is difficult to transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The benzoin fragrance comprises the following components by weight:

[0039] 50 parts of benzoin resin;

[0040] 50 parts of dipropylene glycol;

[0041] Melt the massive benzoin resin at 80-90°C for 6 hours, filter it while it is hot with a 100-200 mesh sieve to obtain the benzoin resin extract, dissolve the obtained benzoin resin extract in dipropylene glycol, and the yield is 94.85% ( Because the benzoin resin has some solid impurities such as branches and leaves of benzoin tree in the inside), get the benzoin resin extract 2g of gained, be dissolved in 2ml dipropylene glycol, it has the characteristic fragrant and sweet smell of benzoin resin, and with obvious vanilla fragrance, The aroma is stronger than the comparative proportion.

Embodiment 2

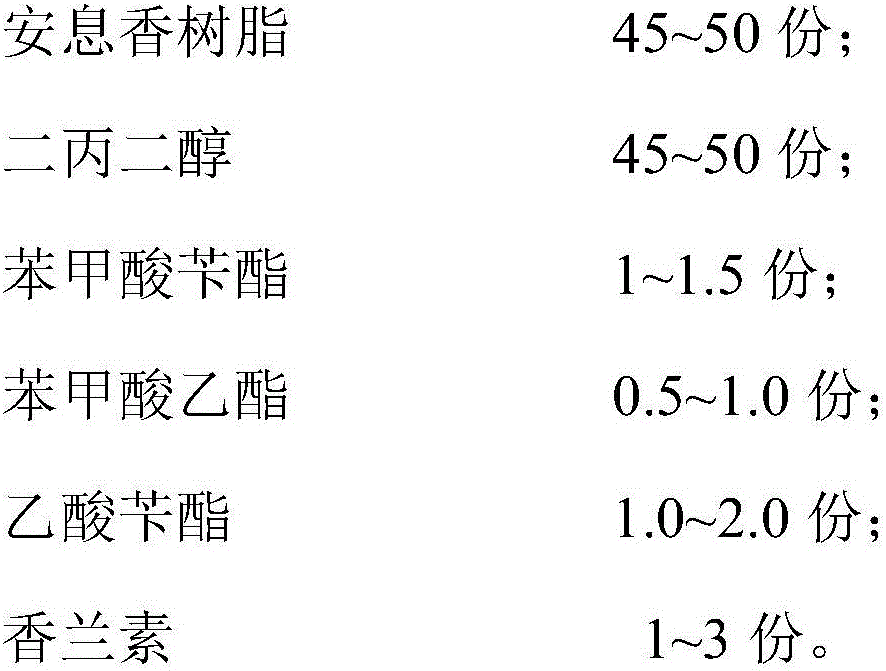

[0043] The benzoin fragrance comprises the following components by weight:

[0044]

[0045] Step (1) heat-melt the benzoin resin at 80-90° C. for 6 hours, filter while hot with a 200-mesh sieve to obtain the benzoin resin extract, and dissolve the obtained benzoin resin extract in dipropylene glycol;

[0046] In step (2), benzyl benzoate, benzyl acetate, ethyl benzoate and hot-melted vanillin are added sequentially in proportion, stirred while adding, and mixed uniformly to obtain benzoin fragrance.

[0047] Vanillin was melted in a water bath at 100°C for 20 minutes.

[0048] The prepared benzoin fragrance has the strong sweet smell of benzoin resin and vanilla smell similar to the benzoin obtained by steam distillation.

Embodiment 3

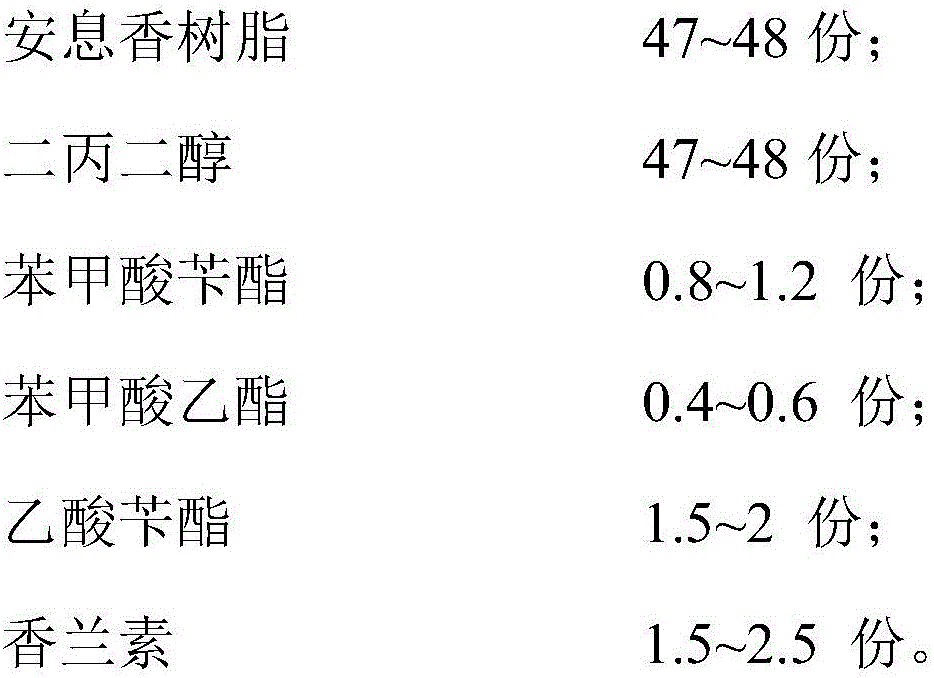

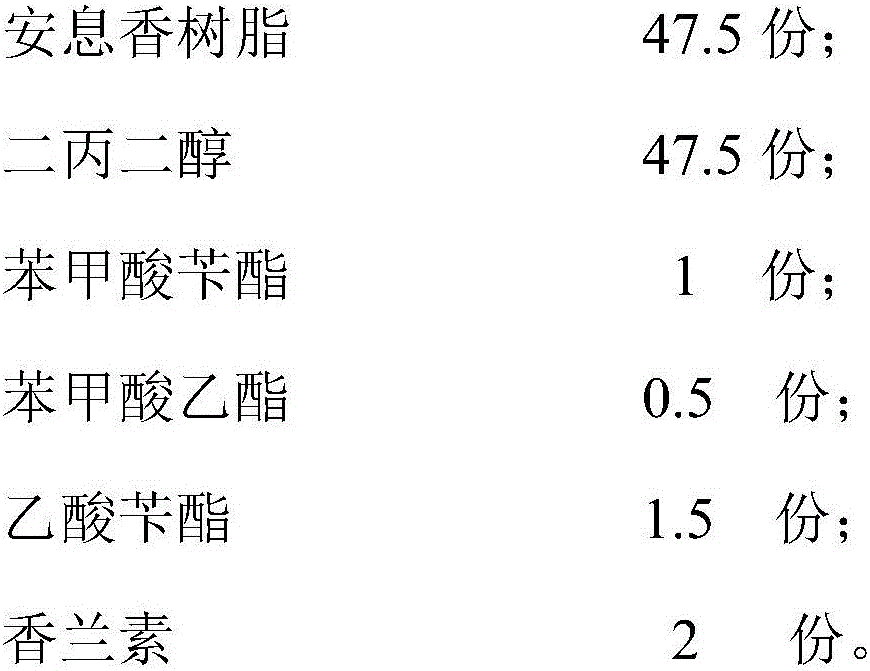

[0050] Benzoin perfume comprises the following components by weight:

[0051]

[0052]

[0053]Step (1) heat-melt the benzoin resin at 80-90° C. for 7 hours, filter while hot with a 200-mesh sieve to obtain the benzoin resin extract, and dissolve the obtained benzoin resin extract in dipropylene glycol;

[0054] In step (2), benzyl benzoate, benzyl acetate, ethyl benzoate and hot-melted vanillin are added sequentially in proportion, stirred while adding, and uniformly mixed to obtain benzoin fragrance.

[0055] Vanillin was melted in a water bath at 95°C for 40 minutes.

[0056] The prepared benzoin fragrance has the strong sweet smell of benzoin resin and vanilla smell similar to the benzoin obtained by steam distillation, and the overall aroma intensity is similar to that of the standard product of benzoin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com