Molded sheet metal part quenching and clamping device

A clamping device and technology of sheet metal parts, applied in the field of mechanical processing, can solve problems such as stamping, bending and forming workpiece deformation, heat treatment quenching deformation, small batch quenching deformation of small sheet metal parts, etc., to achieve small footprint and flexible use Large, the effect of solving the problem of quenching deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail.

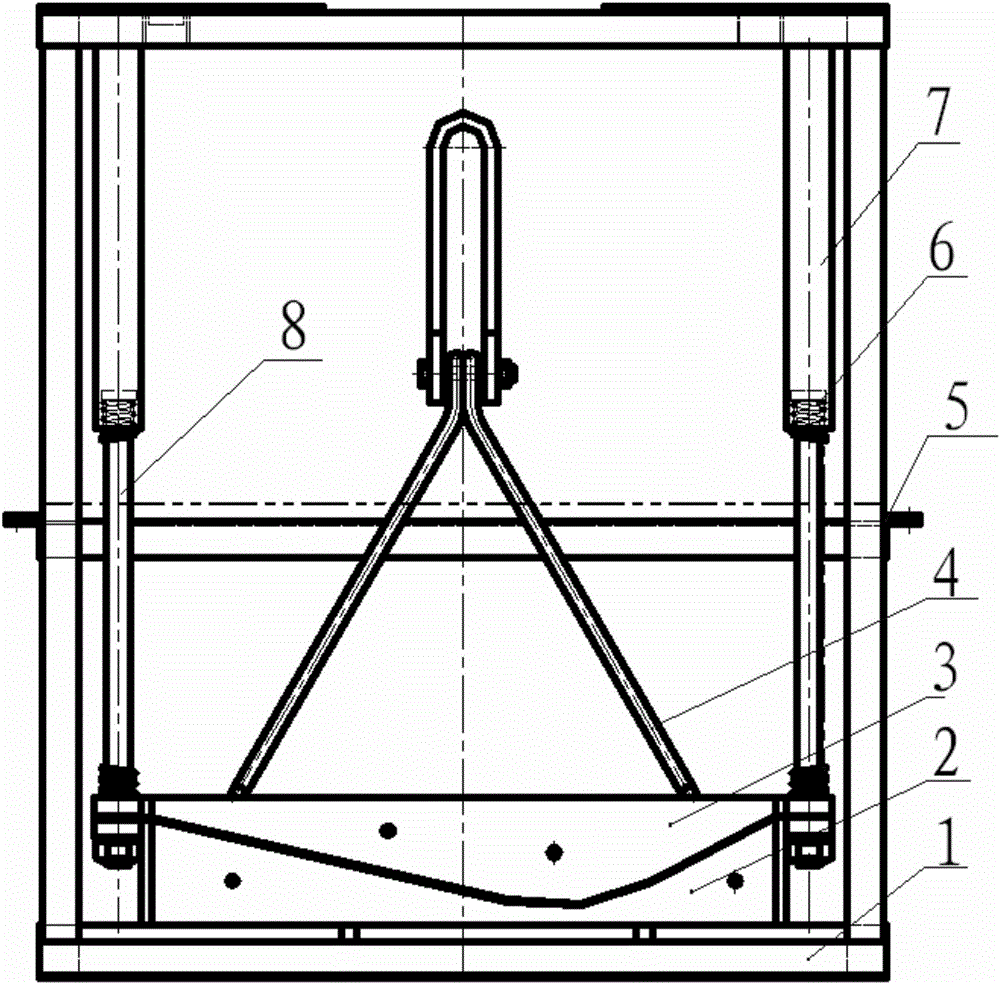

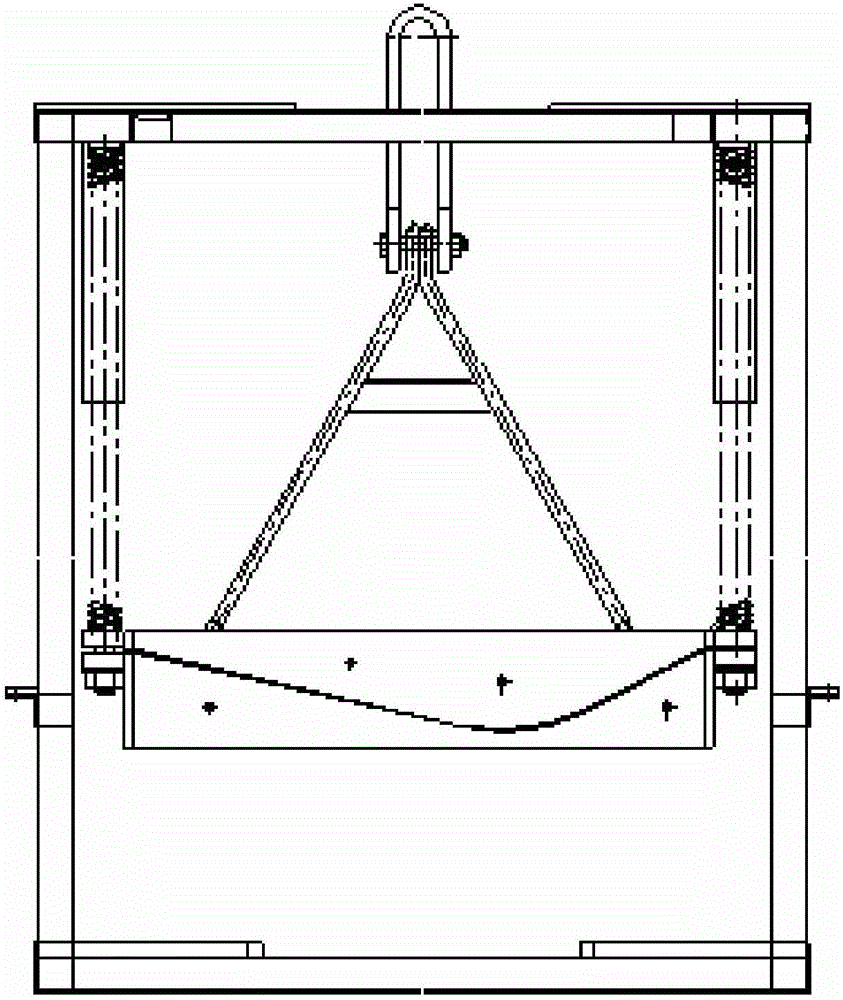

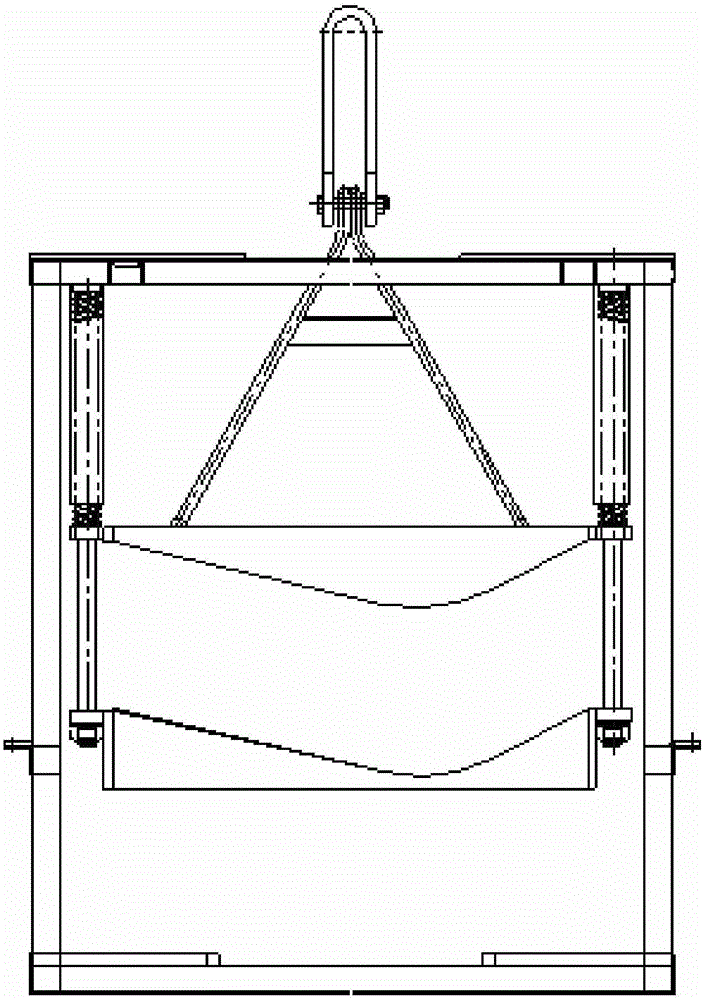

[0012] The present invention provides a quenching thermal clamping device for formed sheet metal parts, which is mainly composed of a bracket 1, a lower die 2, an upper die 3, a lifting fixture 4, a positioning device 5, a clamping spring 6, a sleeve 7 and a guide rod 8; The bracket is fixedly installed on the quenching liquid tank or the fixing device near the quenching liquid tank through the positioning device in the middle. The four sleeves 7 are welded and fixed on the four corners of the upper end of the bracket. The lower end of the lifting fixture is fixed on the upper surface of the upper mold. The guide rod The lower end of the upper end passes through the lugs of the upper and lower molds and is fixedly connected with the nut. The boss at the upper end of the guide rod is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com