Nickel-based alloy and article formed thereby

A technology of nickel-based alloys and articles, which is applied in the field of alloys and can solve problems such as not being able to meet special needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

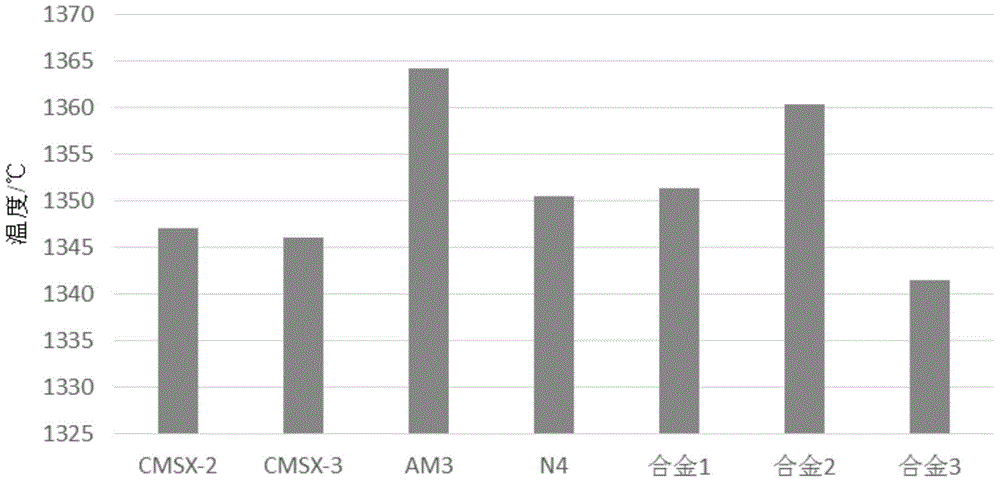

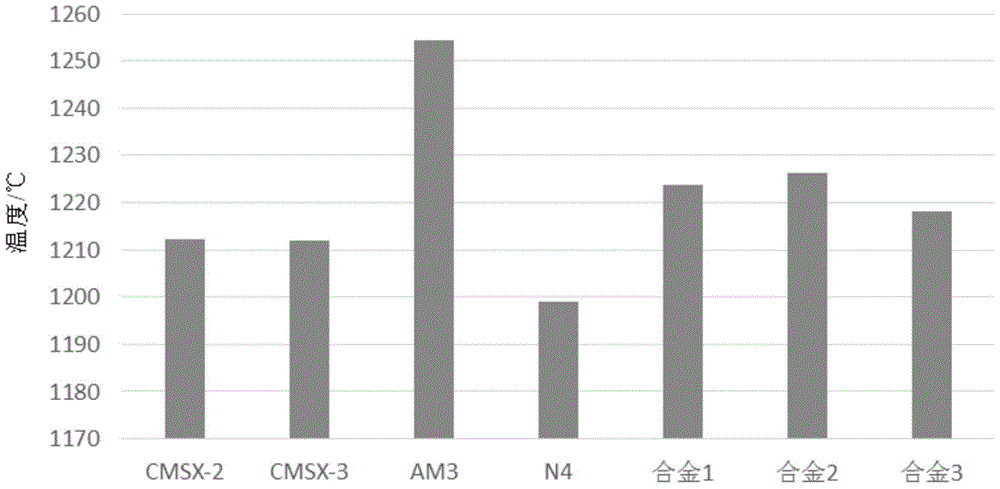

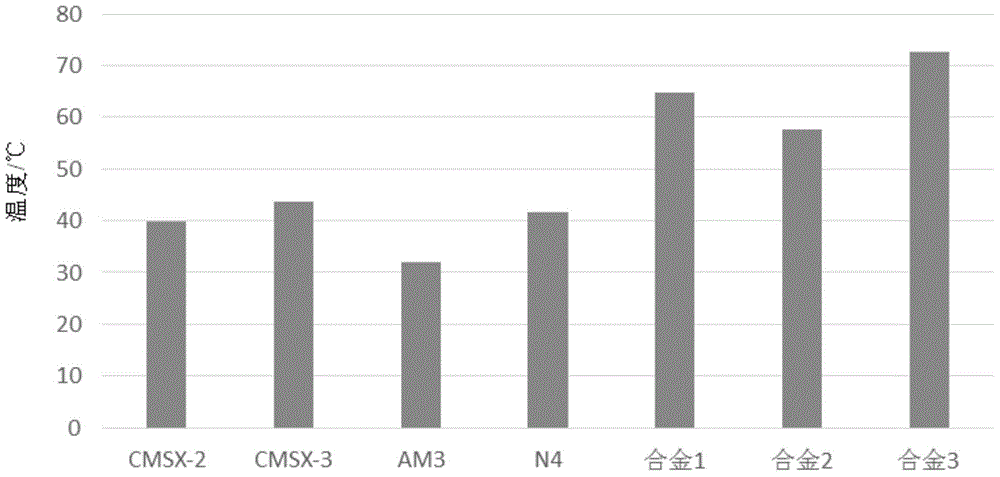

[0089] The nickel-based superalloy ingot was prepared, and its composition is shown in Table 1. The nickel-based alloy provided by this embodiment is compared with the performance of the nickel-based alloy of the prior art, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown; The nickel base alloy of prior art is also obtained by casting. figure 1 It is a contrast bar graph of the initial melting temperature of the nickel-based alloy of the present embodiment and the initial melting temperature of the prior art nickel-based superalloy; figure 2 The solid solution temperature of the strengthening phase γ' in the nickel-based alloy of this embodiment is compared with the prior art nickel-based superalloy; image 3 It is the contrast bar graph of the size of the nickel-based alloy paste region of the present embodiment and the prior art nickel-based superalloy; Figure 4 It is the comparison bar graph of the nickel-based alloy heat treatment window of t...

Embodiment 2

[0091] The nickel-based superalloy ingot was prepared, and its composition is shown in Table 1. The nickel-based alloy provided by this embodiment is compared with the performance of the nickel-based alloy of the prior art, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown; The nickel base alloy of prior art is also obtained by casting. figure 1 It is a contrast bar graph of the initial melting temperature of the nickel-based alloy of the present embodiment and the initial melting temperature of the prior art nickel-based superalloy; figure 2 The solid solution temperature of the strengthening phase γ' in the nickel-based alloy of this embodiment is compared with the prior art nickel-based superalloy; image 3 It is the contrast bar graph of the size of the nickel-based alloy paste region of the present embodiment and the prior art nickel-based superalloy; Figure 4 It is the comparison bar graph of the nickel-based alloy heat treatment window of t...

Embodiment 3

[0093] The nickel-based superalloy ingot was prepared, and its composition is shown in Table 1. The nickel-based alloy provided by this embodiment is compared with the performance of the nickel-based alloy of the prior art, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown; The nickel base alloy of prior art is also obtained by casting. figure 1 It is a contrast bar graph of the initial melting temperature of the nickel-based alloy of the present embodiment and the initial melting temperature of the prior art nickel-based superalloy; figure 2 The solid solution temperature of the strengthening phase γ' in the nickel-based alloy of this embodiment is compared with the prior art nickel-based superalloy; image 3 It is the contrast bar graph of the size of the nickel-based alloy paste region of the present embodiment and the prior art nickel-based superalloy; Figure 4 It is the comparison bar graph of the nickel-based alloy heat treatment window of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com