Novel two-stage and four-section grit removal process

A new process, desander technology, applied in the direction of water/steam pretreatment, etc., can solve the problems that the fibers cannot be boiled cotton seed hulls, cotton stalks, the physical impurity removal effect cannot be achieved, and the internal quality of raw materials has declined, so as to achieve improvement The effect of physical impurity removal, dust reduction, and fiber loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

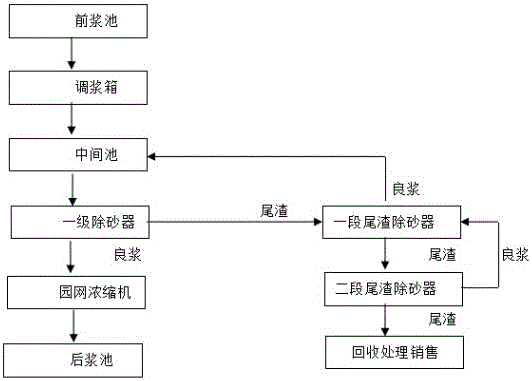

Image

Examples

Embodiment

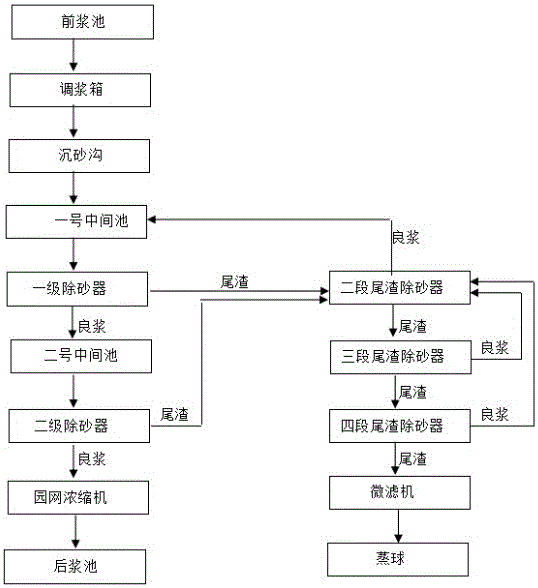

[0017] Such as figure 2 The new two-stage and four-stage desander process shown includes the front stock tank, the slurry mixing box, the grit chamber, the No. 1 intermediate pool, the first desander, the No. 2 intermediate pool, the second desander, The process flow of the garden network thickener and the back pulp tank is as follows:

[0018] From the front slurry tank to the mixing tank, the slurry enters the sand sinking ditch after being mixed and diluted, and hard impurities such as sand and stones are precipitated, and enters the first-level desander through the No. 1 intermediate tank for treatment; the good pulp after the treatment of the first-level desander enters No. 2 intermediate pool, and then enter the secondary desander for treatment; the good pulp treated by the secondary desander is concentrated by the garden net thickener and then enters the back pulp pool.

[0019] It also includes the second-stage tailings desander, the third-stage tailings desander, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com