Full-hydraulic geological core drill

A core drilling rig, full hydraulic technology, applied in the direction of extracting undisturbed core devices, drilling equipment, earthwork drilling and production, etc., can solve the problems of increasing the complexity of drilling rig operation, poor stratum adaptability, engine flameout, etc., and achieve long service life, High work efficiency and the effect of reducing physical labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

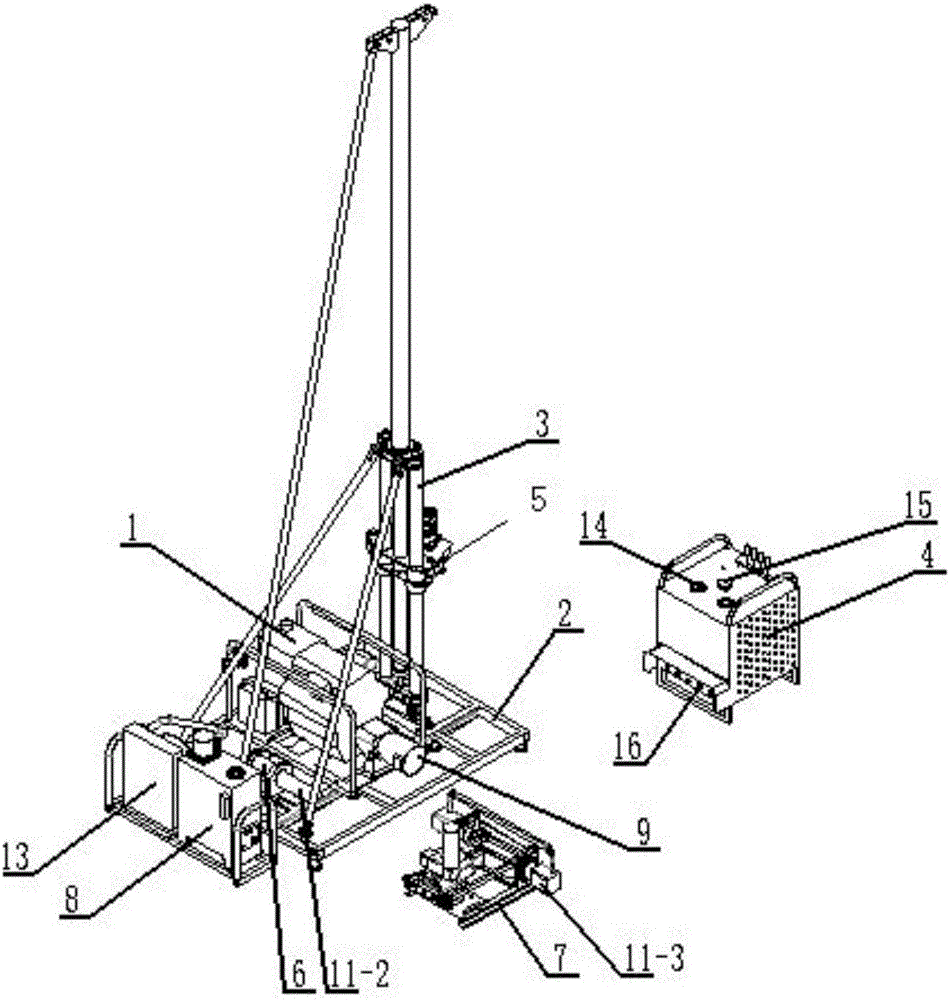

[0023] Please refer to the attached Figure 1-Figure 5 , the present embodiment includes an underframe 2, on which a tower 3, a power assembly 1 and a hoist 6 are installed, and the hoist 6 is connected to the tower 3 through a wire rope 17, and the tower 3 is provided with a power Head 5, the power head 5 is connected to the water pump 7 through the water inlet pipe, and the fully hydraulic geological core drilling machine adopts the remote operation mode.

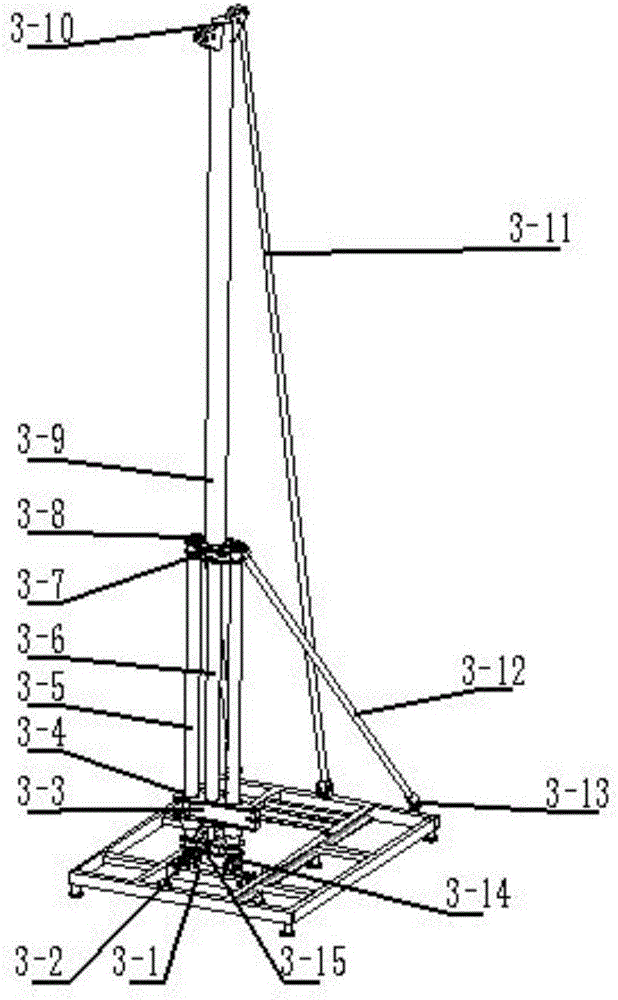

[0024] In this embodiment, the tower frame 3 is installed on the base frame 2, and the tower frame 3 and the base frame 2 form a stable multiple triangular structure to ensure the rigidity and strength requirements of the tower frame 3. The tower 3 includes a connecting frame 3-1, a footage cylinder 3-6, a top seat 3-7, a base 3-2, a winch support 3-9 and a sliding frame 3-3, and the connecting frame 3-1 Fixed on the base frame 2, a base 3-2 is provided above the connecting frame 3-1, and the footage cylinder 3-6 adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com