Oil well produced liquid four-phase separator and manufacturing method thereof

A technology of phase separator and produced liquid, which is applied in separation method, liquid separation, centrifugal separation water/sewage treatment, etc. It can solve the problems of low automation level, manual control of separator, and low separation quality, so as to achieve mechanical automation , realize the effect of automatic liquid discharge and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

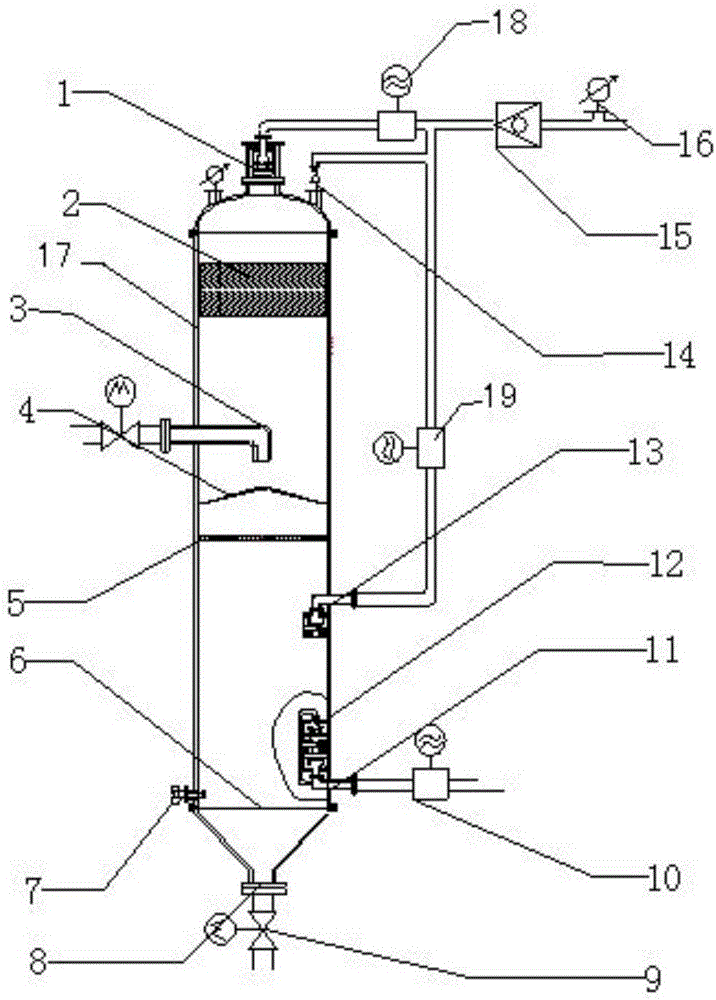

[0036] The present invention will be further described below with reference to the accompanying drawings.

[0037] A four-phase separator for reinjection of produced water from an oil well, comprising a housing 17, the top gas outlet of the housing 17 is provided with an exhaust float valve 1, and the exhaust float valve 1 is connected to one end of a flow meter 18 through a gas pipeline, and the flow rate The other end of valve 18 connects one end of one-way valve 15, one end of overflow valve 14 and one end of flowmeter two 19 by gas pipeline; One end of flowmeter one 18 connects an end of pressure gauge 16; Overflow valve 14 is arranged on The top of the housing 17; the other end of the flow meter 19 is connected to the oil discharge float valve 13 through the oil outlet pipeline, and the oil discharge float valve 13 is arranged on the oil discharge port of the housing 17; the inner cavity of the housing 17 is provided with a mist catcher 2. There is a liquid inlet 3 under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com