Automatic selecting method for well testing data interpretation of oil-water well

An automatic selection, oil-water well technology, applied in the direction of wellbore/well components, earthwork drilling, measurement, etc., can solve the problems of multiple solutions and low accuracy of parameters, so as to improve the accuracy of parameters and solve the problem of multiple solutions of parameters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

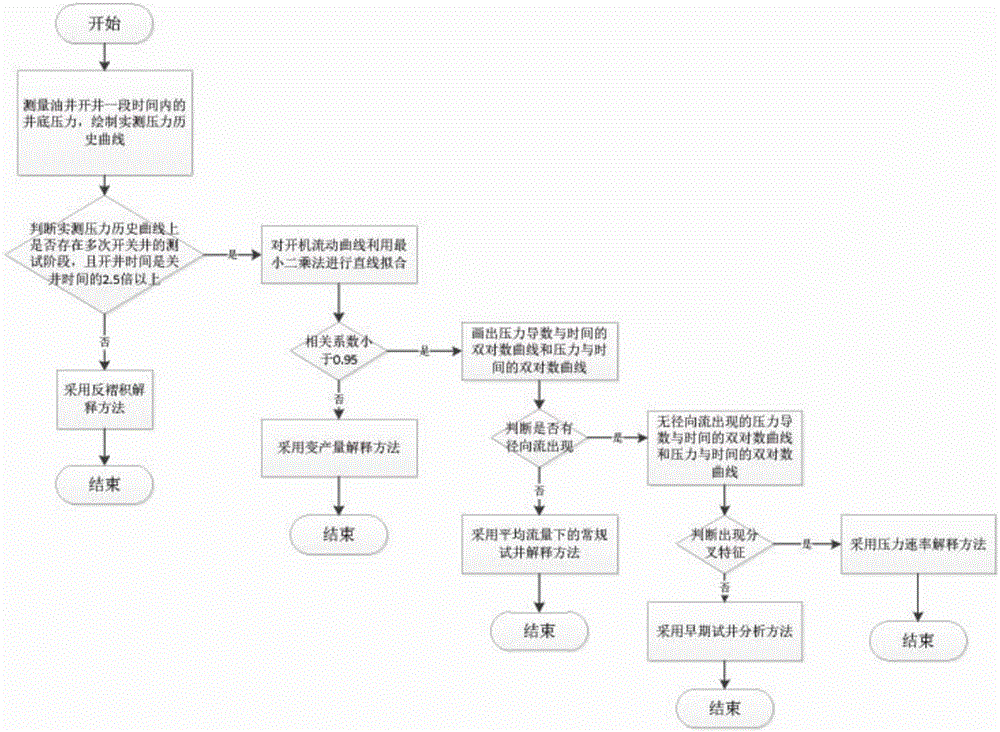

Method used

Image

Examples

Embodiment 1

[0017] The perforated section of Well Nanpu 1-3 is 2745.6-2802.6m, with a thickness of 38.2m, which is interpreted as oil and water in the same layer by logging. On December 19, 2005, oil testing was carried out by using tubing conveyed negative pressure perforation + formation testing + hydraulic pump drainage (production) for oil testing. The well was opened for 66 minutes once, the well was shut down for recovery for 1781 minutes, and the well was opened for the second time. Drainage 60h.

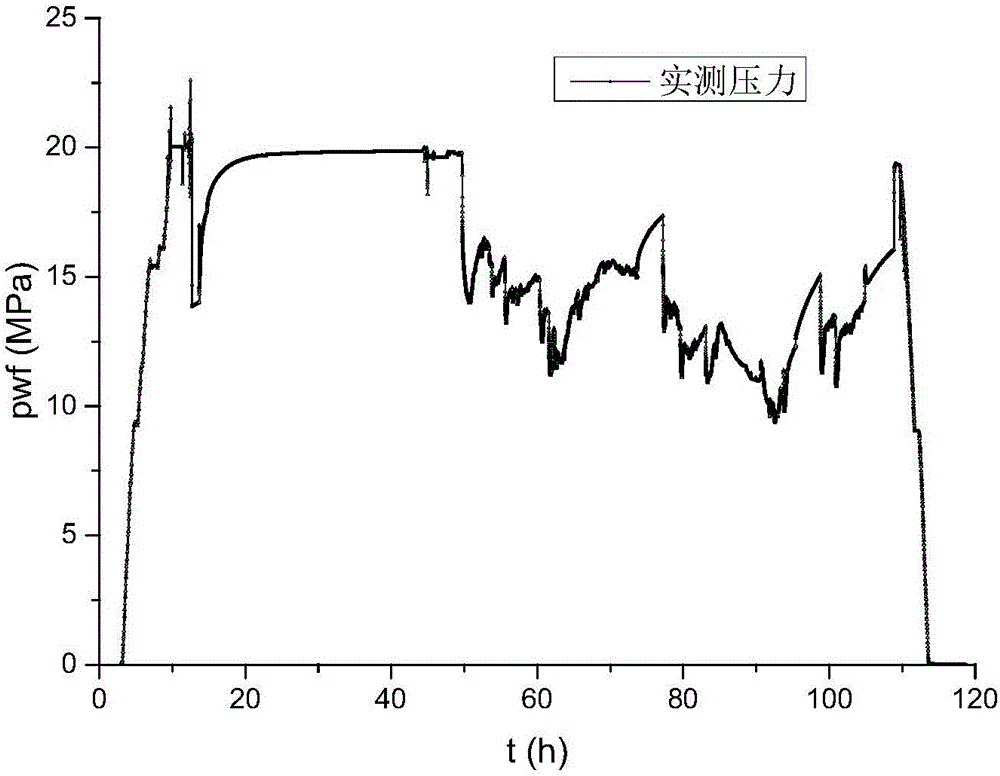

[0018] Step 1: Measure the bottomhole pressure value within the recovery time (1781min) of the shut-in pressure after the oil well has been in production for a period of time (66min), obtain the relationship between the bottomhole pressure and time, and draw the measured pressure history curve, see figure 2 .

[0019] Step 2: Judging whether there are multiple test phases of opening and closing wells on the measured pressure history curve, and the well opening time is more than 2.5 tim...

Embodiment 2

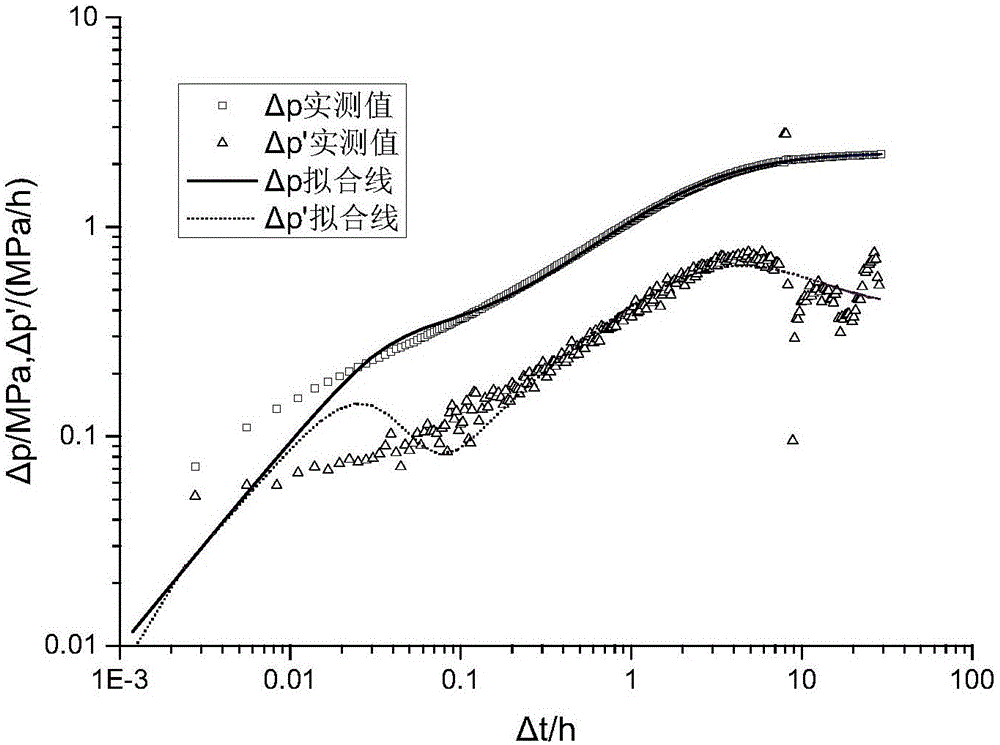

[0023] The test interval of C2-1 layer in well Jian12-54x is 2024.80-2026.80m, with a thickness of 2m, and the logging interpretation is that oil and water are in the same layer. From March 9th to March 19th, 2013, MFE was used as the test process. The test process included one opening, one closing, and two swabbing. One time the well was opened for 90 minutes, and the well was shut down for 1497 minutes.

[0024] Step 1: Measure the bottomhole pressure value within the recovery time (1497min) of the shut-in pressure after the oil well has been in production for a period of time (90min), obtain the relationship between the bottomhole pressure and time, and draw the measured pressure history curve, see Figure 5 .

[0025] Step 2: Judging whether there are multiple test phases of opening and closing wells on the measured pressure history curve, and the well opening time is more than 2.5 times the well closing time. Depend on Figure 5 It can be seen from the test process that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com