Spherical universal coupling

A universal coupling and shaft coupling technology, which is applied in the direction of shaft couplings, elastic couplings, mechanical equipment, etc., can solve problems affecting the quality of strip correction and the accuracy of parallelism of roller shafts, etc., to improve the scope of use , Improve the overall strength and stiffness, and improve the effect of the ability to withstand torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

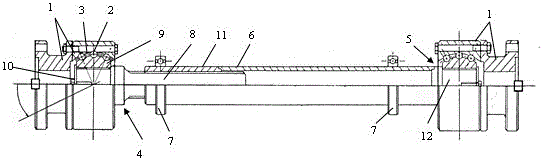

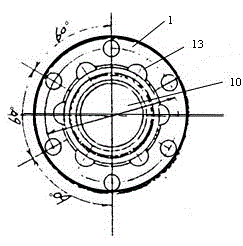

[0023] Such as Figure 1-2 The ball type universal coupling shown includes an outer coupling member 1 with six raceway grooves 13 formed on the inner diameter surface, and six raceway grooves 13 paired with the outer diameter surface of the outer coupling member 1 are formed on the outer diameter surface. The inner coupling member of the first raceway groove 13, the ball 2 sandwiched between the raceway groove 13 of the outer joint member 1 and the raceway groove 13 of the inner joint member for torque transmission, and the retaining ball 2 Cage 3; the inner coupling includes a left inner coupling member 4, a right inner coupling member 5, and a sleeve 6, and the left inner coupling member 4 is connected to the right inner shaft through the sleeve 6 The outer side of the sleeve 6 is sleeved with a bracket bearing 7; the raceway grooves 13 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com