Method for preparing light conversion composite, light conversion film, backlight unit and display device having the same

A composite material and light conversion film technology, which is applied in the field of light conversion composite materials and its preparation, can solve the problems of QD degradation and QD luminous efficiency deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

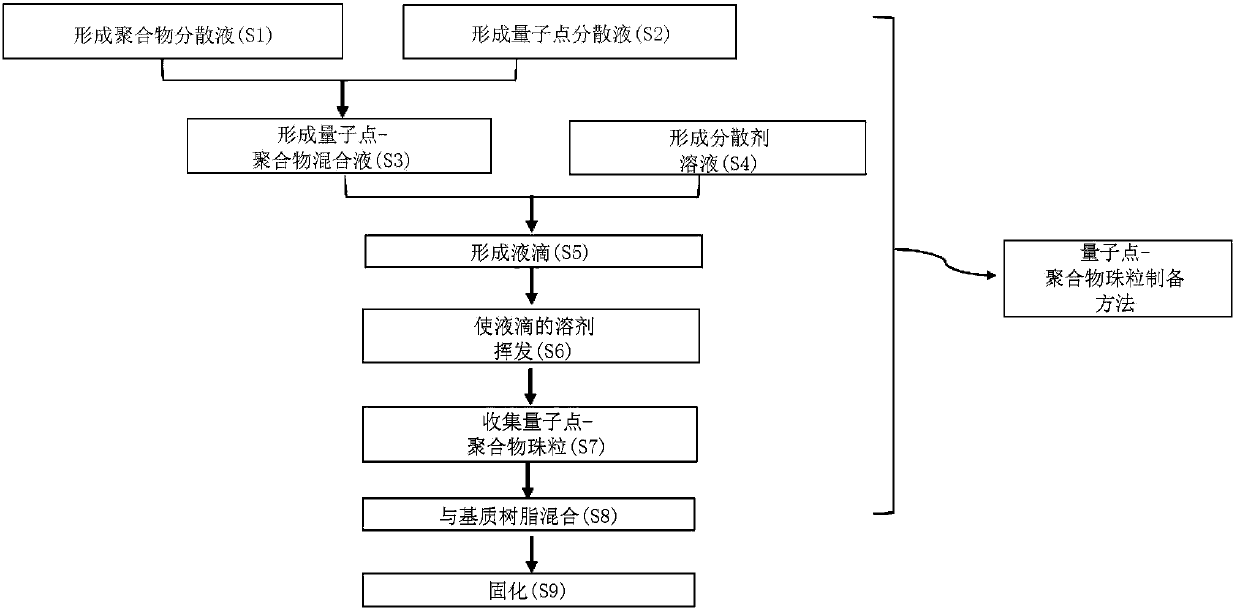

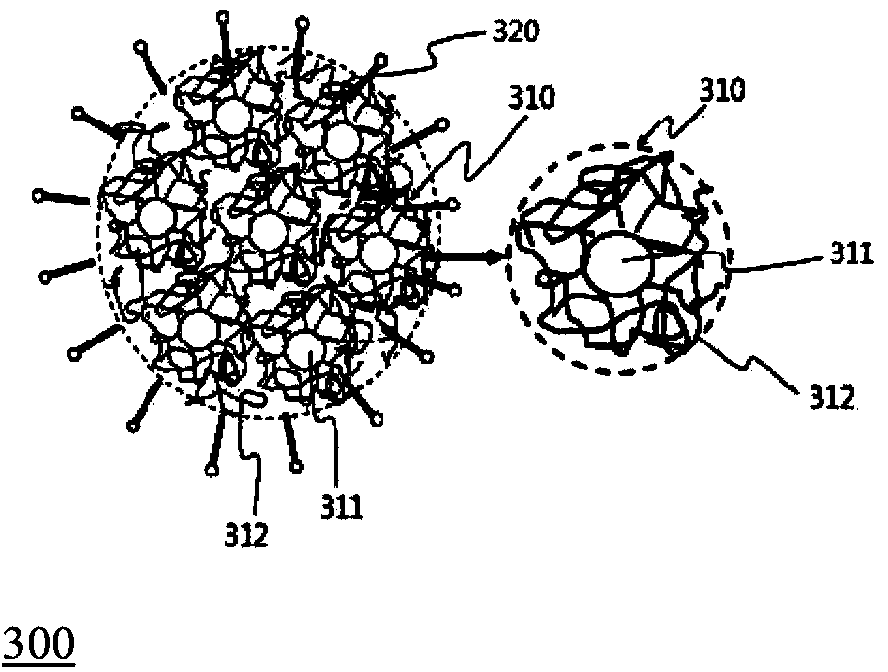

[0033] The method for preparing a light conversion composite material of an embodiment includes: preparing quantum dot-polymer beads; mixing the quantum dot-polymer beads with a matrix resin to form a mixed solution; and curing the mixed solution. Here, quantum dot-polymer beads were prepared by using a solvent evaporation method. According to the present embodiment, when the quantum dot-polymer beads are prepared using the solvent evaporation method, since the quantum dot-polymer beads are prepared without a high-temperature process, it is possible to prevent the quantum dots from deteriorating during the high-temperature process.

[0034] Next, figure 1 is a diagram illustrating a method of producing a light conversion composite material according to an embodiment. In the following, each process will refer to figure 1 for a more detailed description. First, in operation S1, a polymer and a first solvent are mixed with each other to form a polymer dispersion.

[0035] Her...

preparation example 1

[0119] Preparation Example 1: Quantum dot-polymer beads (I)

[0120] The number average molecular weight is about 28,000 g / mol and the solubility parameter is about 22 MPa 1 / 2 The partially oxidized polyester was dissolved in chloroform to prepare a polymer dispersion. The polymer dispersion contained about 25% polyester by weight. The solvent of the ZnCdSe / ZnS quantum dot solution dissolved in toluene was used instead of chloroform to prepare a quantum dot dispersion (70 mg / mL). The quantum dot dispersion is added to the polymer dispersion, and the mixture is stirred to form a quantum dot-polymer mixture. Here, the polymer dispersion and the quantum dot dispersion were mixed with each other such that the quantum dots in the quantum dot-polymer mixture had a content of about 0.5% by weight.

[0121] Polyvinyl alcohol was dissolved in water to form a 1% by weight dispersant solution. After that, about 10 g of the dispersant solution and about 2 g of the quantum dot-polymer ...

preparation example 2

[0125] Preparation Example 2: Quantum dot-polymer beads (II)

[0126] Except using a solubility parameter of about 21.1MPa 1 / 2 Ethylcellulose resin (manufacturer: Sigma-Aldrich) was used instead of polyester and the polymer dispersion and quantum dot dispersion were mixed with each other so that the quantum dots in the quantum dot-polymer mixture had a content of about 1% by weight Otherwise, the same method as in Preparation Example 1 was carried out, thereby preparing quantum dot-polymer beads (II).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com