Dedusting and radiating device for high-voltage harmonic filter

A high-voltage harmonic and heat dissipation device technology, which is applied to household refrigeration devices, lighting and heating equipment, chemical instruments and methods, etc., can solve the problems of single function, incomplete heat dissipation, complicated operation, etc., and achieve multiple economic benefits and complete heat dissipation , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

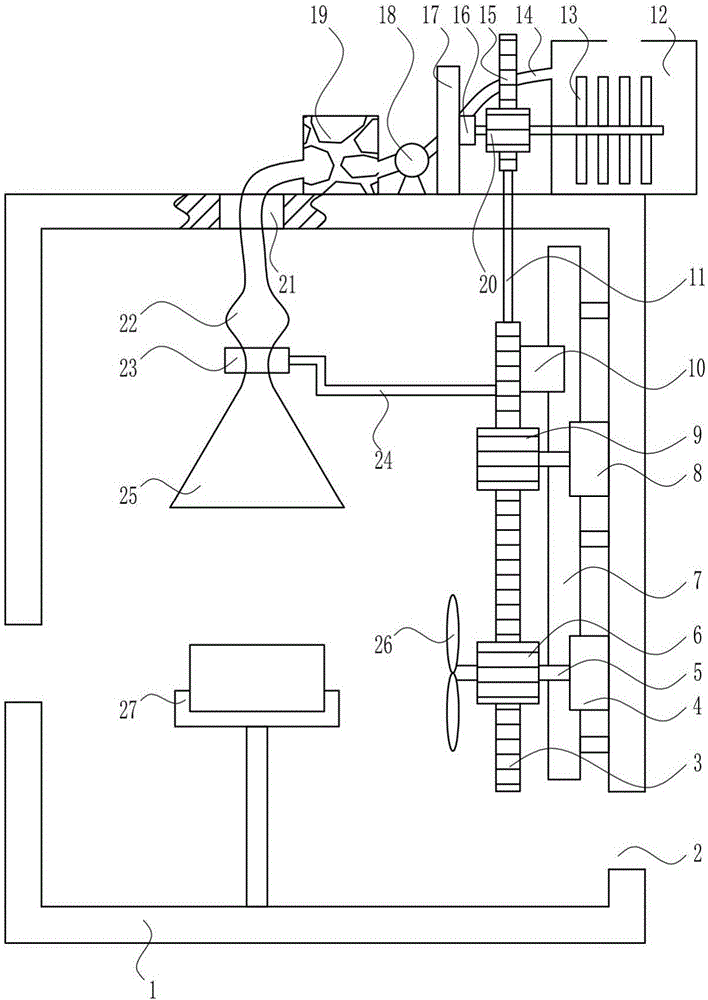

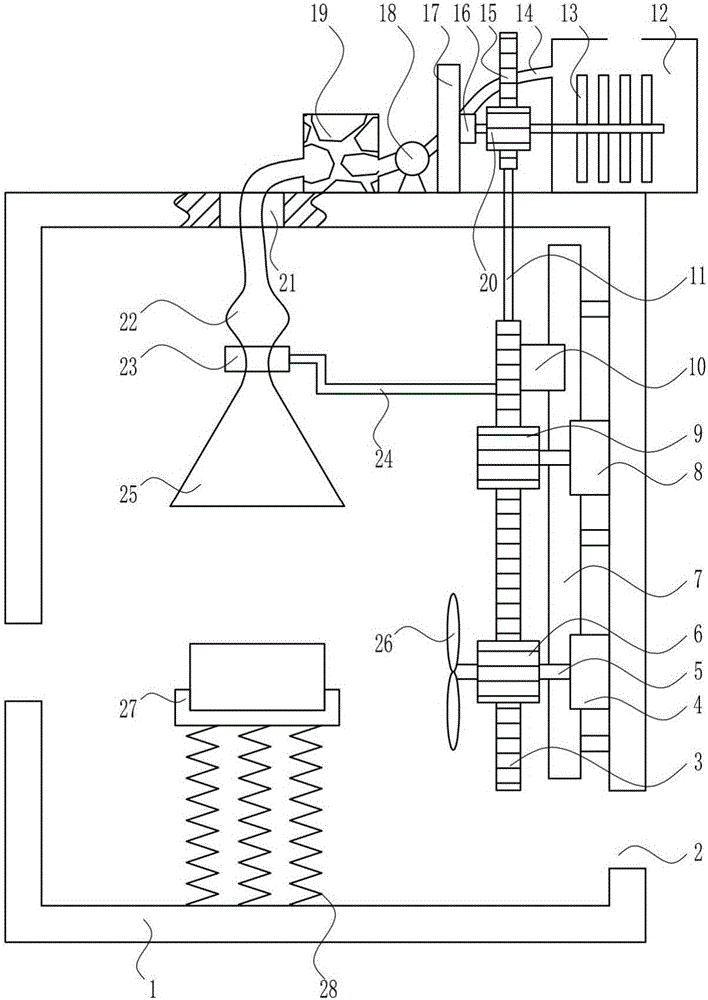

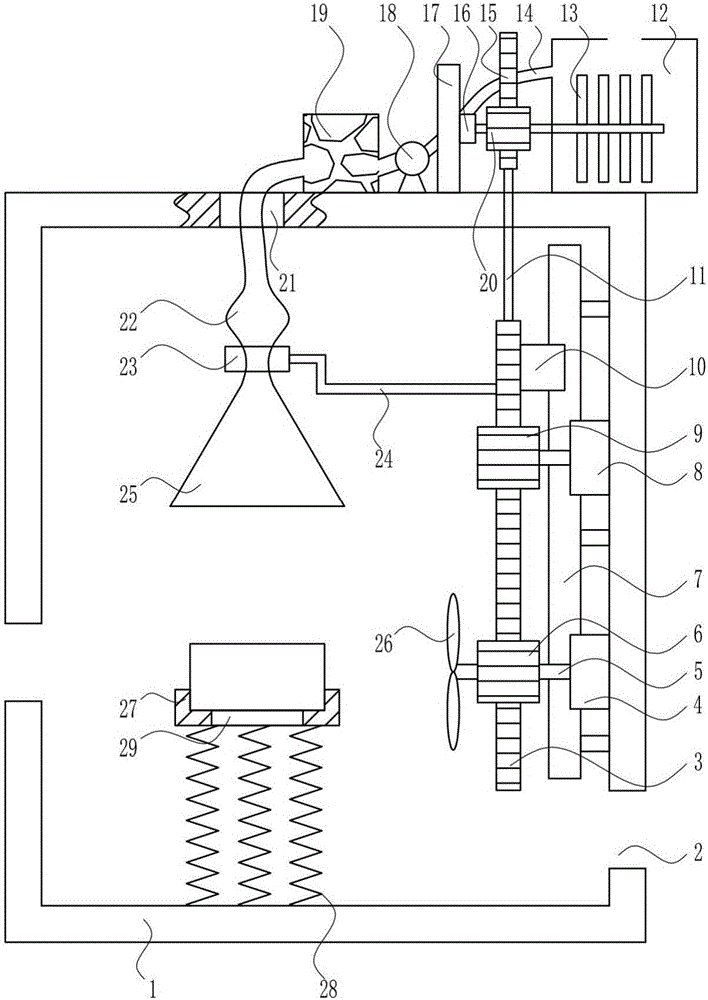

Embodiment 1

[0032] A high-voltage harmonic filter dust removal and cooling device, such as Figure 1-4 As shown, it includes a box body 1, a first rack 3, a first bearing seat 4, a first rotating shaft 5, a first gear 6, a slide rail 7, a motor 8, a second gear 9, a slider 10, a first connection Rod 11, refrigerator 12, stirring rod 13, first hose 14, second rack 15, second bearing seat 16, support plate 17, air pump 18, desiccant box 19, third gear 20, second hose 22. Sliding sleeve 23, second connecting rod 24, jet cover 25, vanes 26 and placement tank 27, openings 2 are opened at the left and right ends of the box body 1, guide holes 21 are opened at the top of the box body 1, and the inner bottom of the box body 1 There is a placement tank 27, the right side of the box body 1 is provided with a motor 8 and a first bearing seat 4, the motor 8 is located above the first bearing seat 4, the left side of the motor 8 is connected with a second gear 9, and the first bearing seat 4 The firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com