Heat exchange module of direct-cooling beverage maker

A technology of heat exchange module and beverage machine, which is applied in the direction of beverage preparation device, heat exchanger type, indirect heat exchanger, etc. It can solve the problems of inconvenient movement, large volume of direct cooling beverage machine, and non-compliance with food hygiene and safety. , to achieve the effect of increasing the heat exchange area and heat exchange time, eliminating food hygiene and safety hazards, and shortening the cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

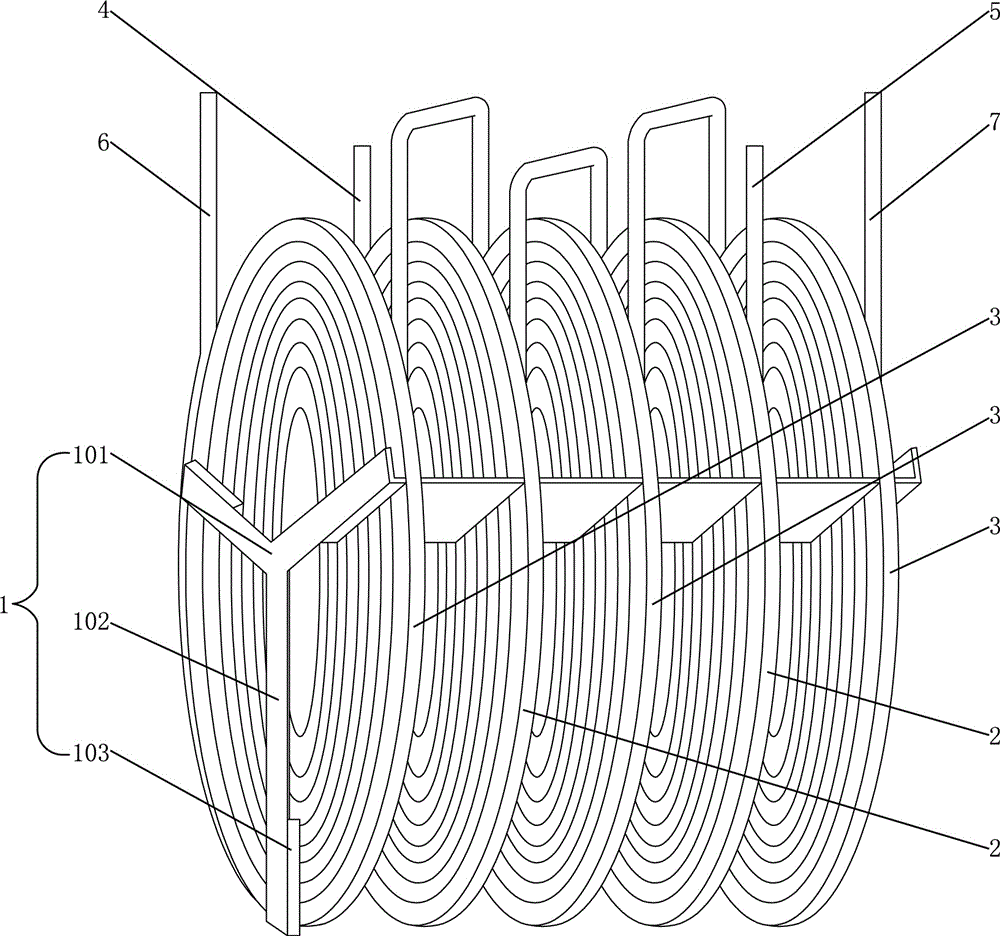

[0019] Such as figure 1 As shown, the heat exchange module of this direct cooling beverage machine includes a bracket 1, a cast aluminum module (covered outside, figure 1 omitted), two refrigerant spiral coils 2 and three cold water spiral coils 3; Both are located between two adjacent cold water spiral coils 3; the refrigerant spiral coil 2 and the cold water spiral coil 3 are wrapped in the cast aluminum module, and the refrigerant spiral coil 2 and the cold water spiral coil 3 are closely connected with the cast aluminum module Contact fit; among each refrigerant spiral coil 2, the output port of the previous refrigerant spiral coil 2 is connected to the input port of the next refrigerant spiral coil 2, and only the input port of the first refrigerant spiral coil 2 and the last The output port of a refrigerant spiral coil 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com