TOFD near surface dead zone defect locating detection method based on wave-type transformation

A technology of positioning detection and detection method, which is applied to measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves, etc. problems, to achieve the effect of strong applicability, reduction of near-surface blind spots, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

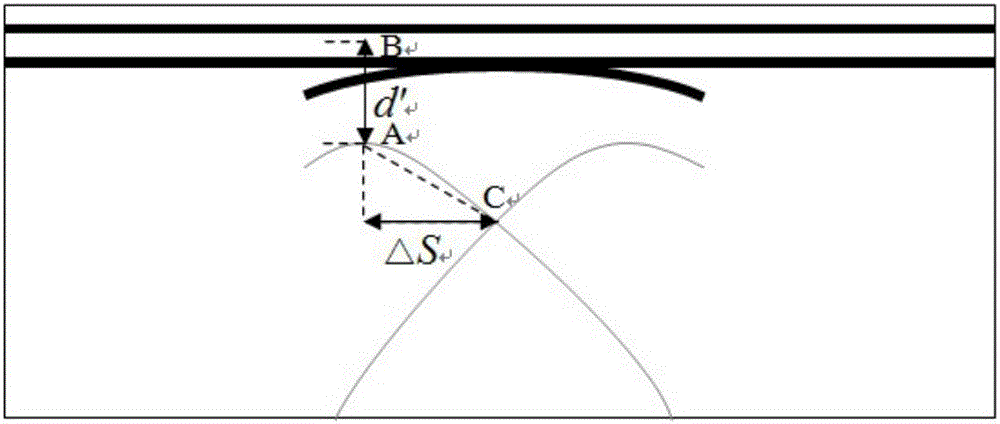

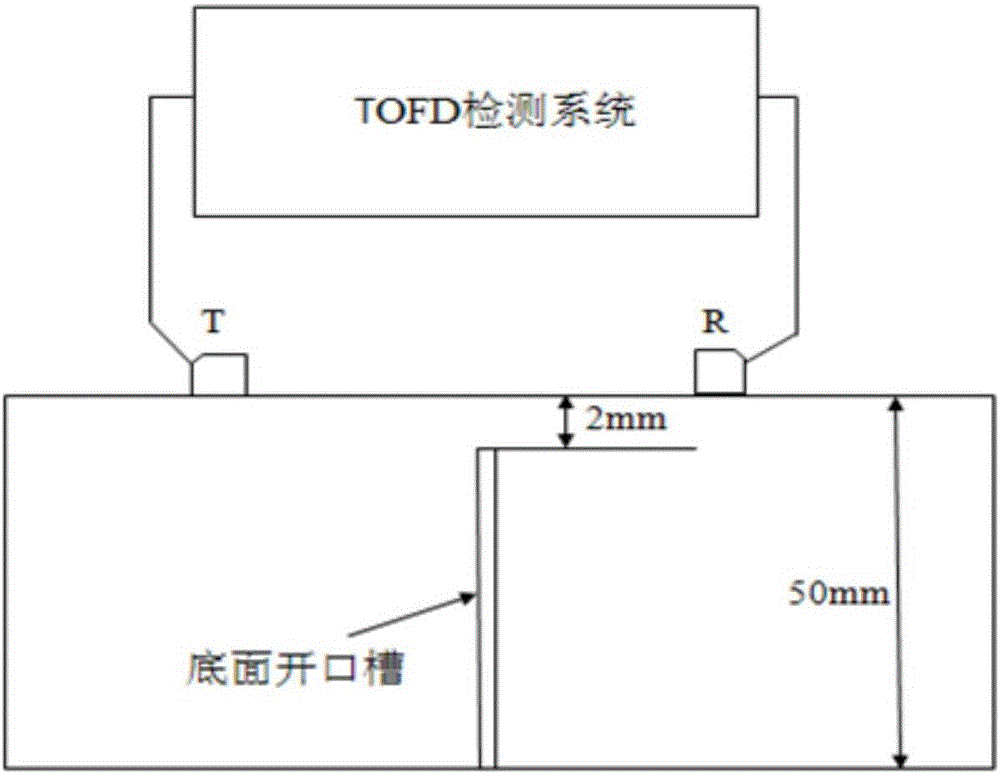

[0016] figure 1 Schematic diagram of deformation wave location in B-scan images. In the quantitative detection method of near-surface defects based on deformation wave, the ultrasonic testing system used is as follows: figure 2 As shown, it includes a TOFD ultrasonic detector, a pair of TOFD probes with a nominal frequency of 10MHz, a pair of longitudinal wave wedges with a deflection angle of 60°, and a scanning device.

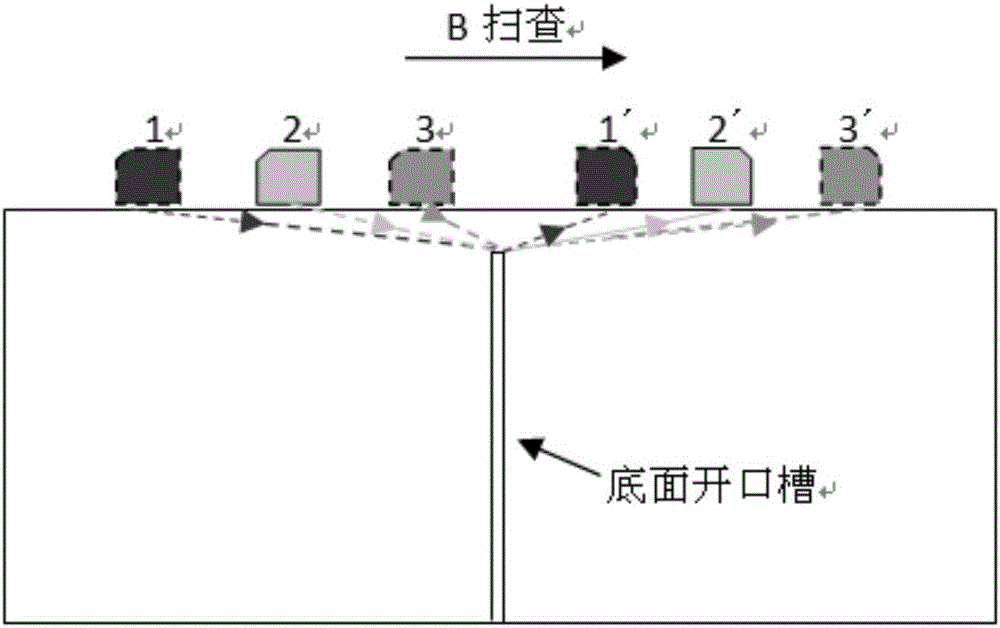

[0017] Next, the method of the present invention is verified by using a carbon steel test block provided with an open groove on the bottom as the test object. The specific verification process and results are as follows:

[0018] The test object is a carbon steel test block, the thickness of the carbon steel test block is 50.00mm, and the sound velocity of longitudinal wave of the material is 5.90km / s. The bottom open groove is 2.00mm deep from the detection surface. A TOFD ultrasonic detector is used, and a pair of TOFD probes and wedges with a probe n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com