Distributed sensing fiber sound emission fusion perception system and running method

A sensing fiber and sensing system technology, applied in the field of distributed sensing fiber optic acoustic emission fusion sensing system, can solve the problems of poor resistance to electrical interference, large system, too many cables, etc., to reduce monitoring costs, high Spatial resolution, simple effect of structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

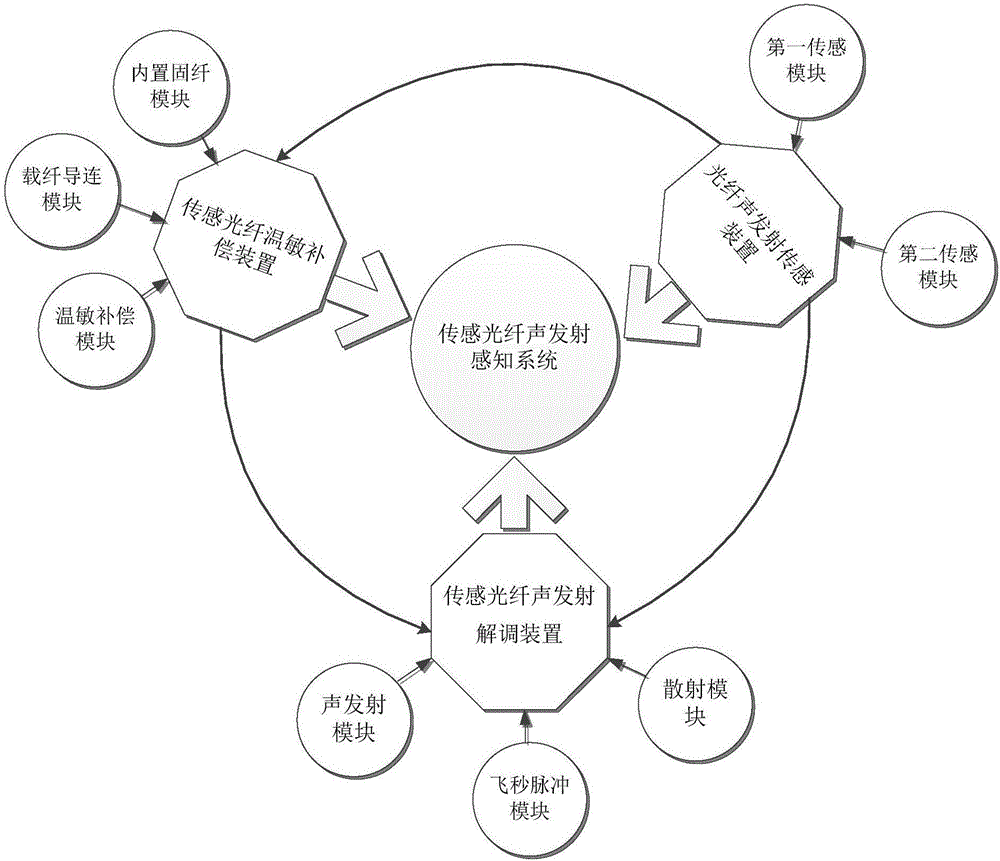

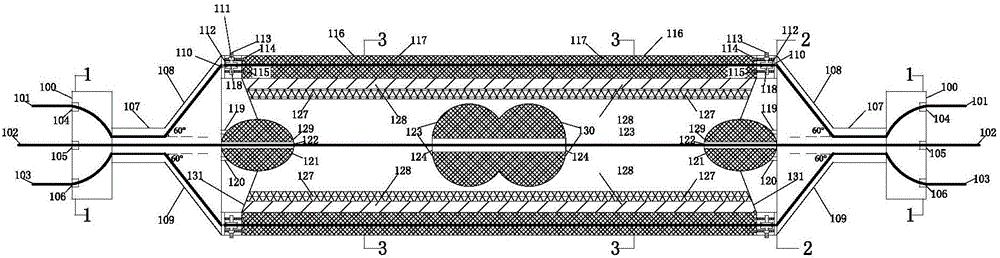

[0031] Such as Figure 1 to Figure 8 As shown, a distributed sensing optical fiber acoustic emission fusion sensing system of the present invention includes a sensing optical fiber temperature-sensitive compensation device and a sensing optical fiber acoustic emission demodulation device, and the sensing optical fiber in the sensing optical fiber temperature-sensitive compensation device passes through After compensation, it enters into the sensing optical fiber acoustic emission demodulation device.

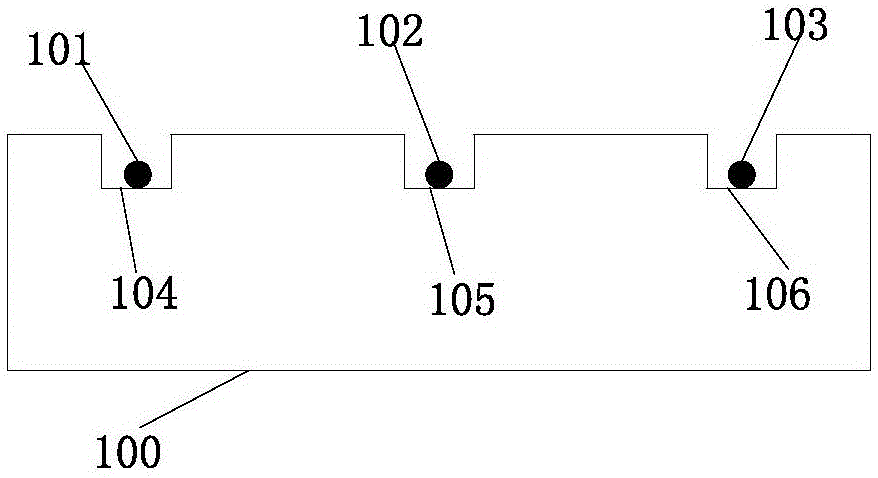

[0032] A sensor optical fiber temperature-sensitive compensation packaging device of the present invention includes a fiber-carrying guide connection module, a built-in fixed fiber module, and a temperature-sensitive compensation module. The fiber carrying and connecting module includes an optical fiber holding platform 100 with a length of 20 cm, a width of 10 cm, and a height of 5 cm, an upper fiber slot 104 with a slot depth of 2 cm, a middle fiber slot 105 with a slot depth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com