Method for predicting aluminium bottle internal coating solidification quality based on sensory evaluation

A technology of inner coating and aluminum bottle, which is applied in the direction of coating, forecasting, and devices for coating liquid on the surface, which can solve the problems of lack of standard simulants, time-consuming and energy-consuming, etc., and achieve the improvement of coating materials and baking Craftsmanship, quality improvement, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

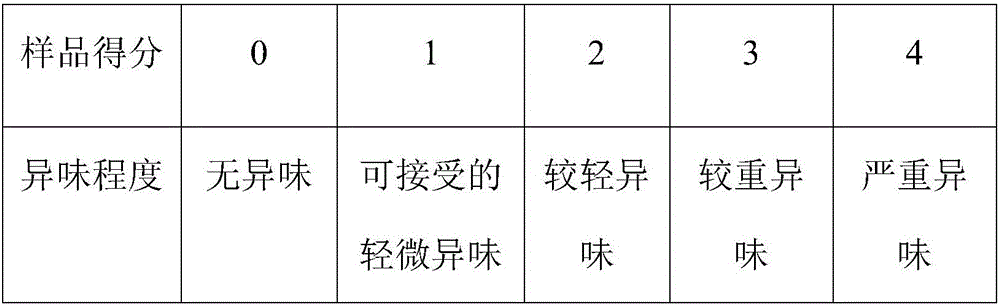

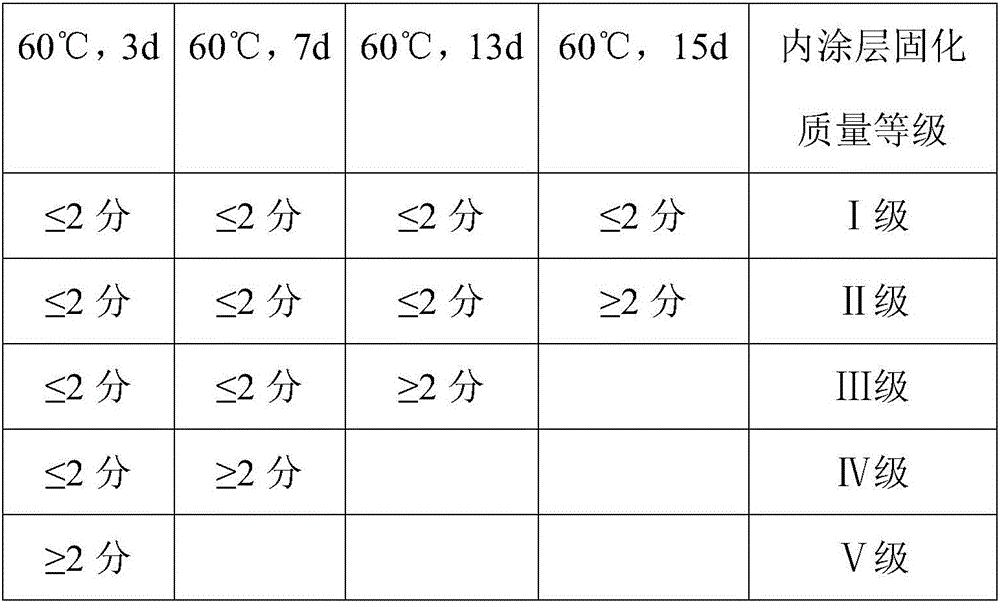

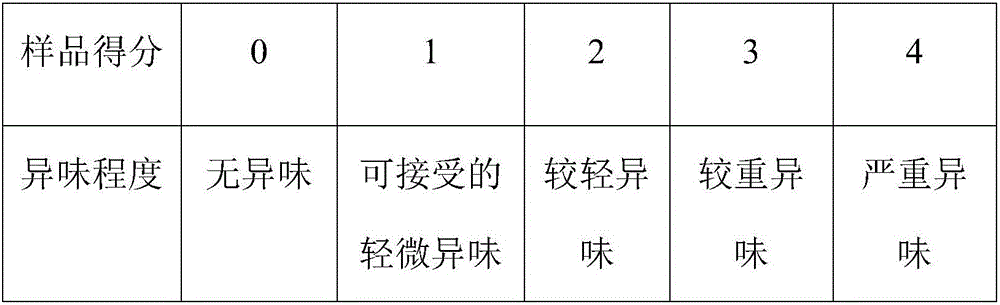

Method used

Image

Examples

Embodiment 1

[0027] step 1:

[0028] (1) Take 20 aluminum bottles of the same batch (capacity is 350ml) from the production line, wash them three times with pure water that meets the first-grade water in the analytical laboratory, and then add 3.5% ethanol aqueous solution (food grade anhydrous water) at 60°C (prepared by ethanol plus first-grade water in the analysis laboratory) as the content simulation liquid, the content is added to a distance of 5mm-6mm from the bottle mouth, automatically sealed by the capping machine, and then put into an ultrasonic extraction constant temperature device that has been heated to 60°C. Incubate at 60°C for 35 minutes under the action of 40KHz ultrasonic waves, and carry out constant temperature extraction;

[0029] The ultrasonic extraction constant temperature device is provided with the top of the vertical rotating shaft, and the capped aluminum bottle containing the simulated liquid of the content is vertically fixed on the rotating shaft, rotates ...

Embodiment 2

[0050] Select 20 aluminum bottles from the same batch as in Example 1, rinse them three times with pure water conforming to the first-grade water in the analytical laboratory, add more than 300mL of beer of the standard process of the brewery, reach the bottle mouth at 5mm-6mm, and seal the cap Afterwards, according to the method and steps of Example 1, extraction and aging were carried out and sensory evaluation was carried out. The obtained sensory scores are shown in Table 6. The curing quality of the inner coating is grade II, which is consistent with the evaluation of the content simulation liquid in Example 1, indicating that the content simulates The liquid can simulate the actual beer content.

[0051] Table 6

[0052]

Embodiment 3

[0054]Select 20 aluminum bottles of the same batch as in Example 1, rinse them three times with pure water meeting the first-grade water in the analytical laboratory, add 3.5% ethanol to the 5mm-6mm of the bottle mouth, and place the bottle at room temperature (25°C) after sealing. ) were stored for 3 months, 6 months, 12 months and 14 months respectively, and then scored by means of the sensory evaluation of the steps (3) and (4) of Example 1, the sensory scores are as follows in Table 7, the curing quality of the inner coating The grade is II, which is consistent with the evaluation results of Example 1 using ultrasonic constant temperature extraction and accelerated aging, indicating that ultrasonic constant temperature extraction and accelerated aging can simulate the shelf life under normal temperature storage.

[0055] Table 7

[0056] 25℃,3m

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com