Horizontal pipeline type boron concentration detection equipment of nuclear power plant

The technology of detection equipment and horizontal tube is applied in the field of boron concentration detection equipment, which can solve the problems of unsatisfactory and low accuracy of boron concentration, and achieve the effect of optimizing design, improving detection level and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

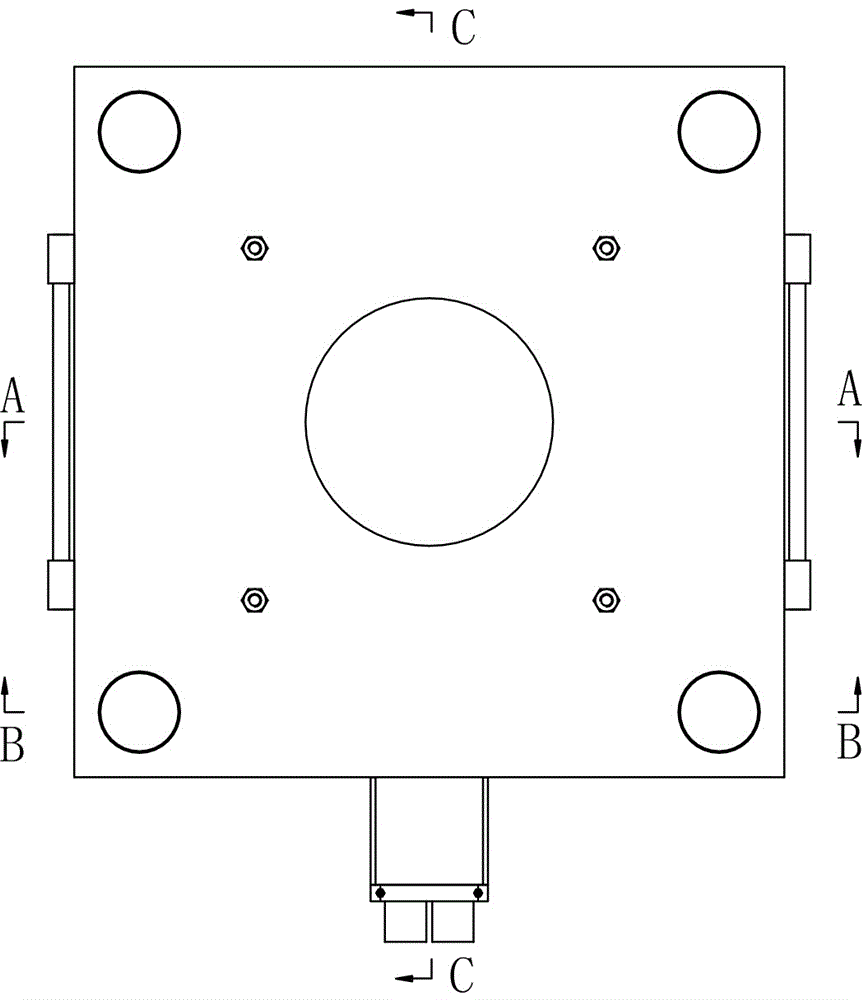

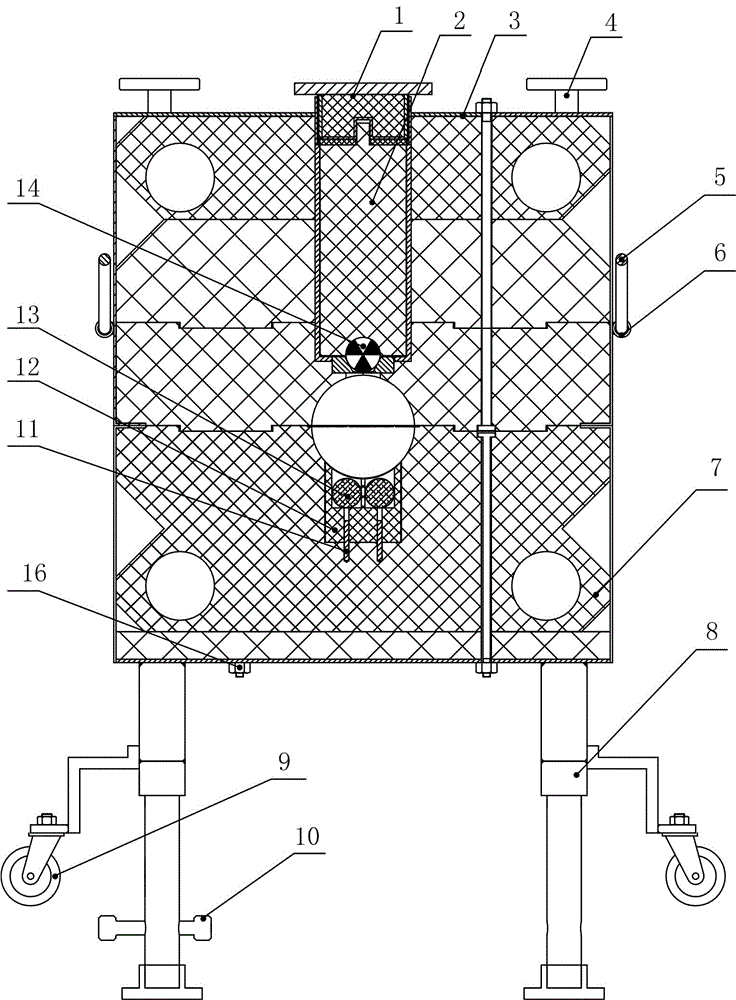

[0040] Nuclear power plant horizontal pipeline boron concentration detection equipment, such as figure 1 and figure 2 As shown, it includes a neutron source generating assembly arranged above the chemical volume pipeline for emitting neutrons, a neutron source detection assembly arranged below the chemical volume pipeline for detecting neutrons, wrapped outside the neutron source generating assembly so that The emitted neutrons enter the upper shielding assembly in the chemical containment pipeline, and the lower shielding assembly 7 wrapped outside the neutron source detection assembly makes the neutrons passing through the chemical containment pipeline enter the neutron source detection assembly.

[0041] In this embodiment, the neutron source in the neutron source generation assembly is located directly above the chemical volume pipeline, and the detector in the neutron source detection assembly is located directly below the chemical volume pipeline, and the neutron source...

Embodiment 2

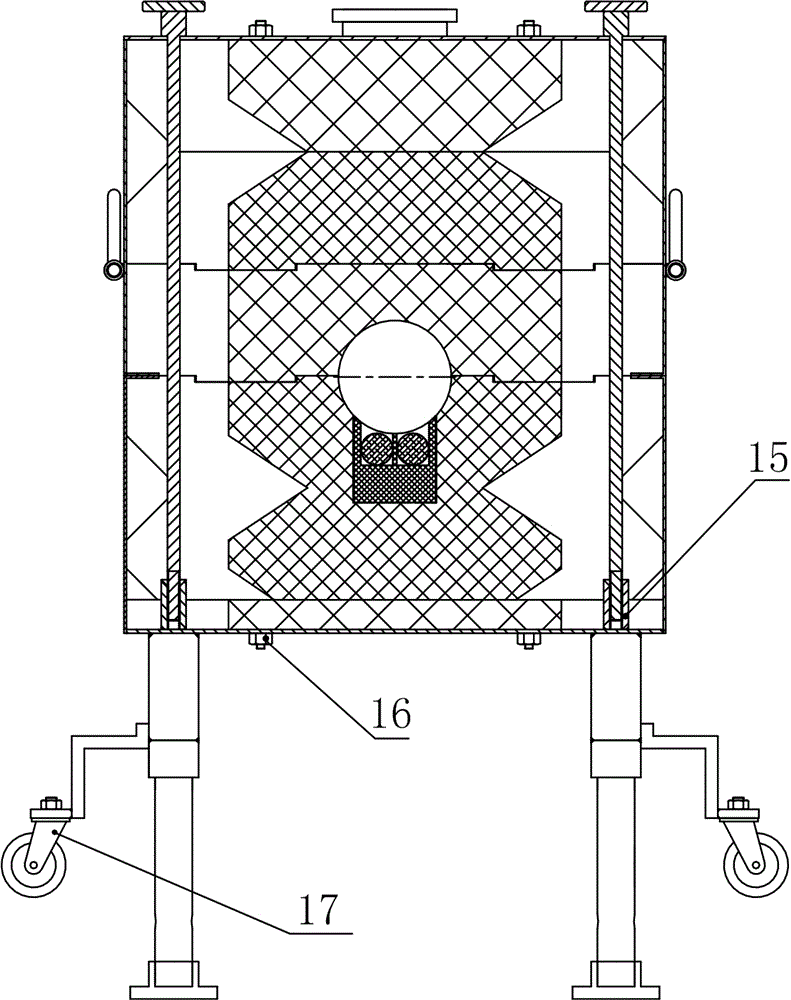

[0048] The difference between this embodiment and Embodiment 1 is that this embodiment optimizes the specific structures of the neutron source generation assembly and the neutron source detection assembly, such as figure 2 , image 3 and Figure 4 As shown, the specific setting method is as follows:

[0049] The neutron source generating assembly is arranged in the upper shielding assembly, and the neutron source generating assembly consists of the neutron source mounting base 2, the neutron source 14 arranged at the bottom of the neutron source mounting base 2 near the chemical containment pipeline, and the The neutron source assembly cover 1 on the top of the neutron source mount 2 is composed. Wherein, the bottom of the neutron source mount 2 is provided with a V-shaped positioning block 18, and the neutron source 14 is fixed on the V-shaped positioning block 18, as Figure 7 shown.

[0050] The neutron source component cover 1 and the neutron source mounting base 2 ar...

Embodiment 3

[0062] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that in this embodiment, the specific structure of the upper shielding assembly and the lower shielding assembly is optimized, and the specific setting method is as follows:

[0063] Both the upper shielding assembly and the lower shielding assembly 7 in this embodiment are made of polyethylene.

[0064] The upper shielding assembly is composed of more than two polyethylene shielding blocks 3 arranged overlappingly, and a positioning structure is also arranged between two adjacent polyethylene shielding blocks 3 . In this embodiment, the number of polyethylene shielding blocks 3 in the upper shielding assembly is three, and the three polyethylene shielding blocks 3 and the shell are fixed as a whole by connecting rods and M8 bolts, such as figure 2 shown.

[0065] The lower shielding assembly 7 is composed of a housing and a polyethylene shielding block arranged above the housing. The polyethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com