Helically grooved folded waveguide

A folded waveguide and helical groove technology, which is applied in the directions of waveguides, waveguide-type devices, traveling wave tubes, etc., can solve the problems of beam-wave interaction efficiency, overall performance degradation of devices, and relative bandwidth limitation of folded waveguide traveling wave tubes, etc. Working bandwidth, the effect of increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

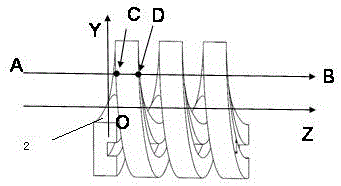

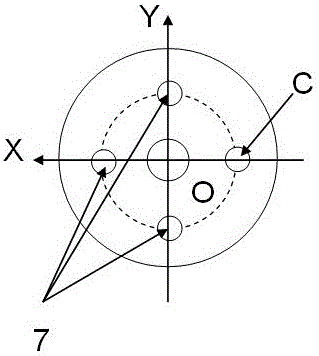

[0028] Such as figure 1 and 2 shown.

[0029] The helical groove folded waveguide includes three shortest waveguide periods 2 and input and output waveguides 1 that are successively connected and repeated along the Z-axis direction.

[0030] The intersection of a straight line AB parallel to the Z axis and any one of the shortest waveguide periods is a continuous line segment CD.

[0031] Four linear electronic channels 7 are provided. The straight beam path 7 is parallel to the Z axis. The straight electron beam channel 7 coincides with the straight line AB. The line segment CD passes through the maximum amplitude point of the electric field strength of the electromagnetic wave in the shortest waveguide period. That is to say, the straight electron channel 7 passes through the position of the maximum electric field intensity in the spiral groove folded waveguide.

[0032] The two end faces of the shortest waveguide period are single-ridge rectangular waveguides; the bro...

Embodiment 2

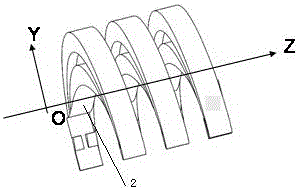

[0036] Such as image 3 shown.

[0037] Compared with Embodiment 1, the only difference is that: the two ends of the shortest waveguide period are double-ridge rectangular waveguides; the broadside of any end surface of any of the shortest waveguide periods is parallel to the Y-axis direction, and the The double ridges of the double ridge rectangular waveguide are respectively located on the two broad sides of the waveguide.

Embodiment 3

[0039] Such as Figure 4-10 shown. Compared with implementation example 1, the difference is only in:

[0040] Both ends of the shortest waveguide period are parallel to the YZ plane. The shape of both ends of the shortest waveguide period is rectangular; the broad sides of any shortest waveguide period are parallel to the Y-axis direction.

[0041]The 6 shortest waveguide periods of the spiral groove folded waveguide are arranged on a cylindrical inner conductor 9 ; the outer surfaces of the multiple shortest waveguide periods coincide with the outer surface of the cylindrical inner conductor 9 .

[0042] The spiral groove folded waveguide also includes two outer conductors 9a; the inner surfaces of the outer conductors 9a coincide with the outer surfaces of the cylindrical inner conductor 9; all the outer conductors 9a seal the outer surface of the inner conductor.

[0043] A total of 8 linear electron beams are provided.

[0044] We have given several implementation exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com