High-power hybrid type direct current circuit breaker

A DC circuit breaker, hybrid technology, applied in circuit devices, emergency protection circuit devices for limiting overcurrent/overvoltage, emergency protection circuit devices, etc., can solve long insulation recovery time, reduce service life, reliable operation Reduce the number of times and other problems to achieve the effect of fast insulation recovery time and fast energy transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

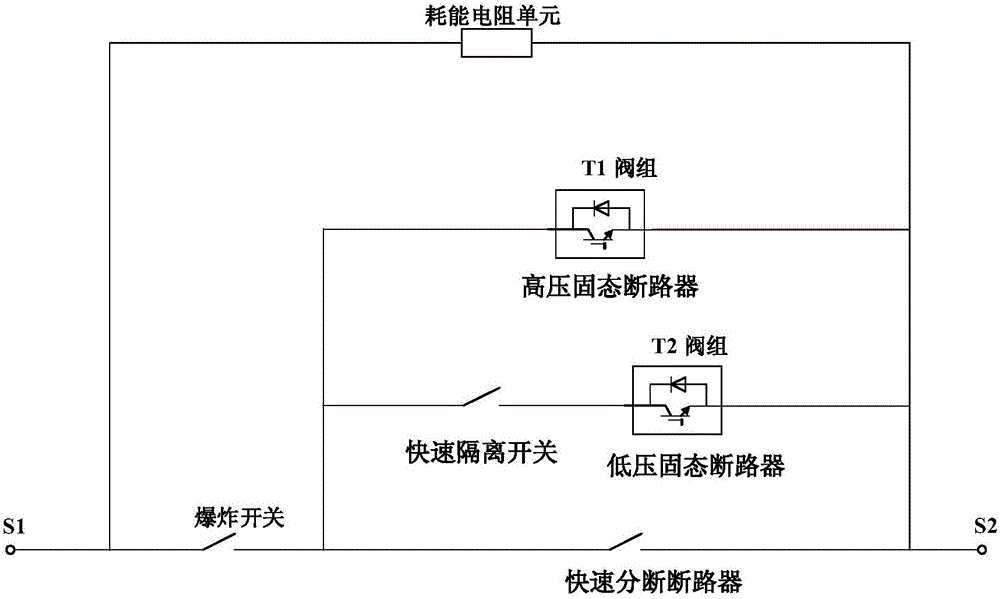

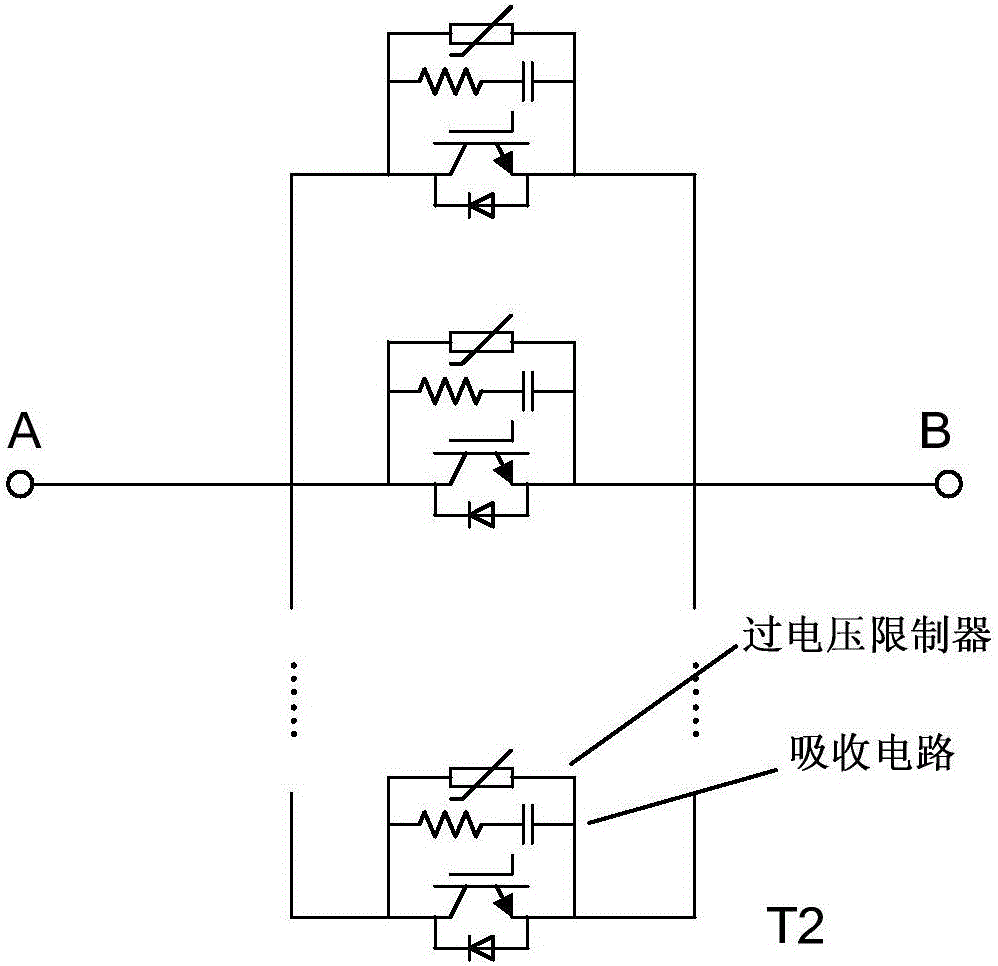

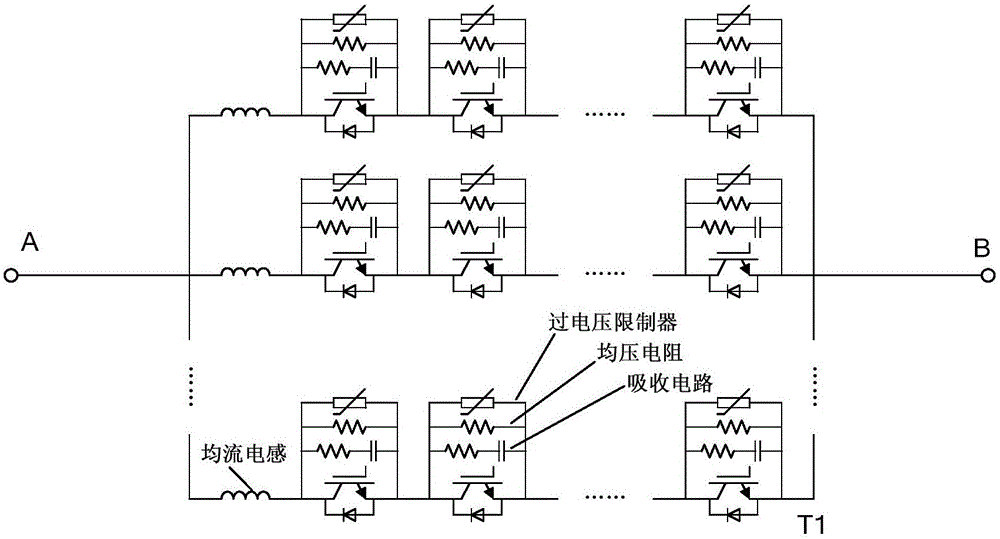

[0022] see figure 1 , 2 3. A high-power hybrid DC circuit breaker, including a mechanical circuit breaker, a solid state circuit breaker, an explosion switch and an energy dissipation resistor, the mechanical circuit breaker includes a quick breaking circuit breaker and a quick isolating switch, and the solid state circuit breaker includes a low voltage Solid-state circuit breaker and high-voltage solid-state circuit breaker; fast disconnecting switch and low-voltage solid-state circuit breaker are connected in series to form the first-stage current transfer branch, and high-voltage solid-state circuit breaker constitutes the second-stage current transfer branch. The primary current transfer branch is connected in parallel to form the main protection switch unit, then connected in series with the backup protection unit formed by the explosion switch, and finally connected in parallel with the energy dissipation branch formed by the energy dissipation resistance unit.

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com