Liquid-cooled motor shell

A technology of liquid-cooled motors and housings, which is applied in the direction of casings/covers/supports, electrical components, electromechanical devices, etc., which can solve the problems of small convective heat transfer coefficient, large boundary layer thickness, poor heat dissipation effect, etc., and achieve pressure Small loss, short flow path length, reduced thermal resistance and temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

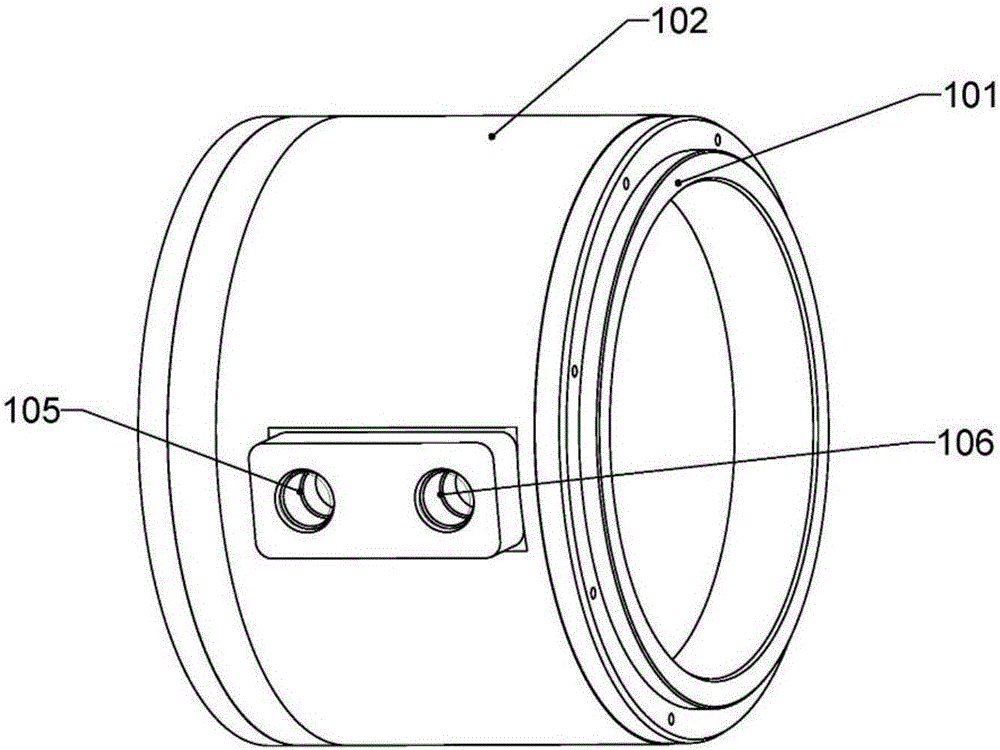

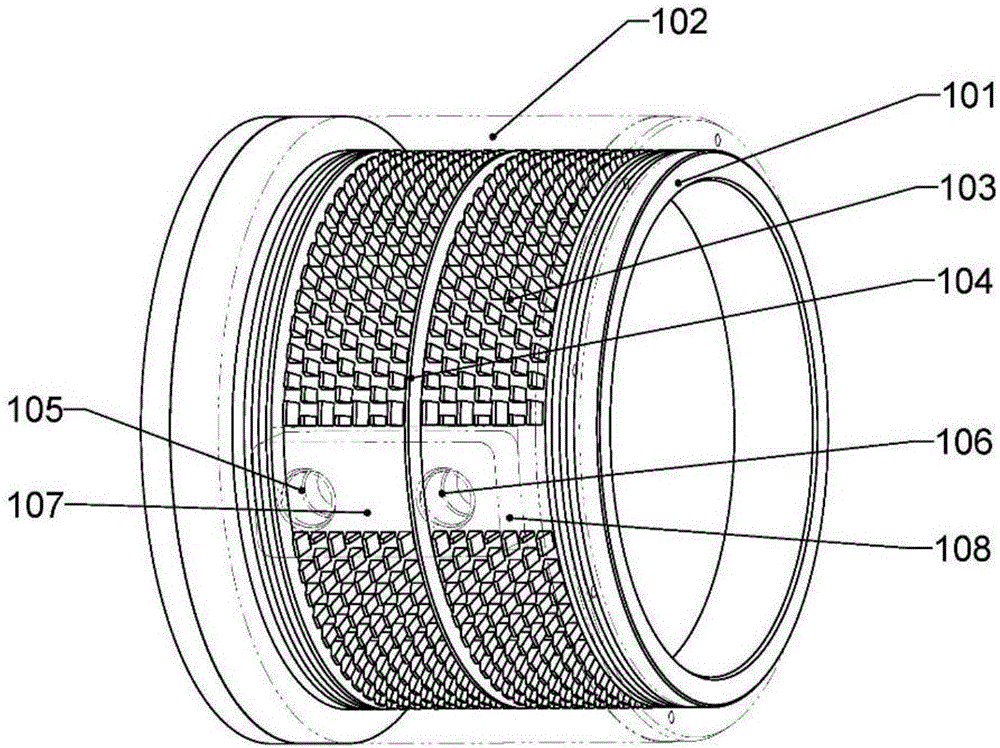

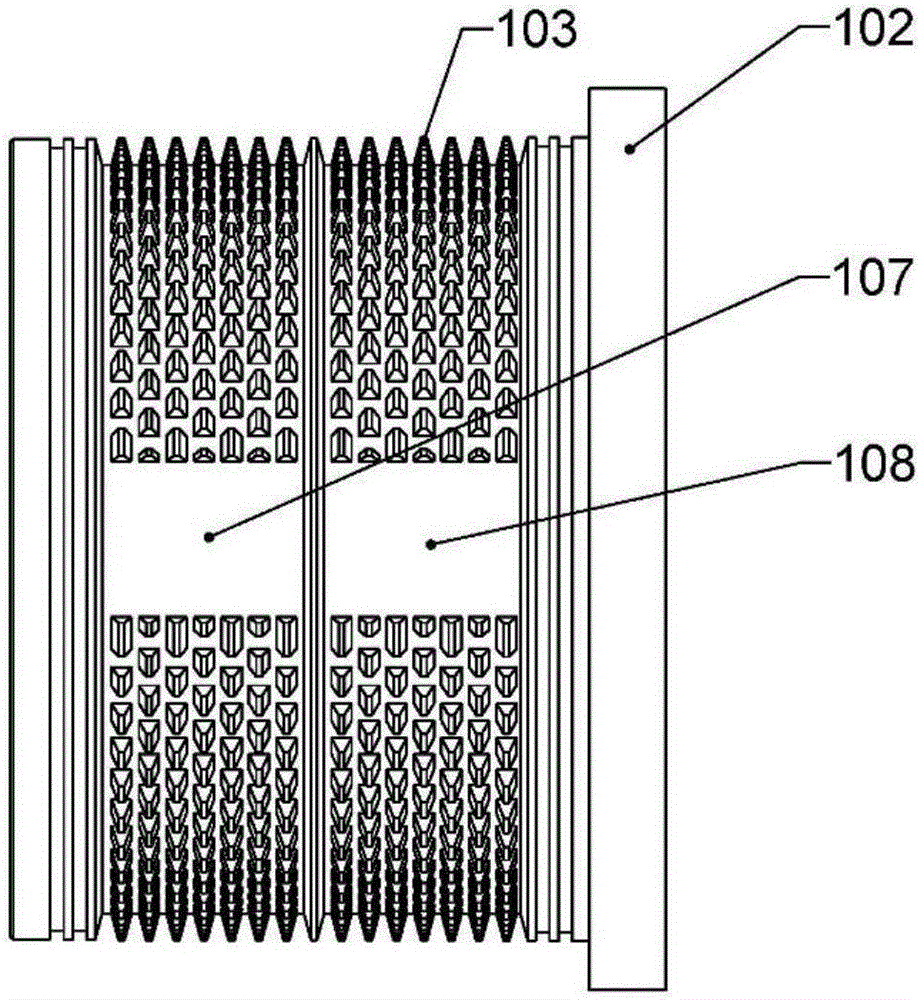

[0027] Such as figure 1 As shown in -8, a liquid-cooled motor casing includes an inner casing 101 and an outer casing 102, and the outer casing 102 is sleeved outside the inner casing 101, wherein the outer casing 102 is provided with a water inlet 105 and Water outlet 106, on the inner shell 101, corresponding to the water inlet 105 and the water outlet 106, there are respectively provided with an inlet part flow channel confluence area 107 and an outlet part flow channel confluence area 108, and the inner shell 101 is on the axis There is a turning and converging area 109 for the cooling liquid, and several rows of isolation ribs 104 are provided on the inner casing 101 for controlling the flow direction. The converging area 107, On both sides of the flow channel confluence area 108 and the flow channel turning confluence area 109 at the exit site, between the inner shell 101 and the outer shell 102, there are zigzag ribs 103, and the zigzag ribs 103 are arranged on the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com