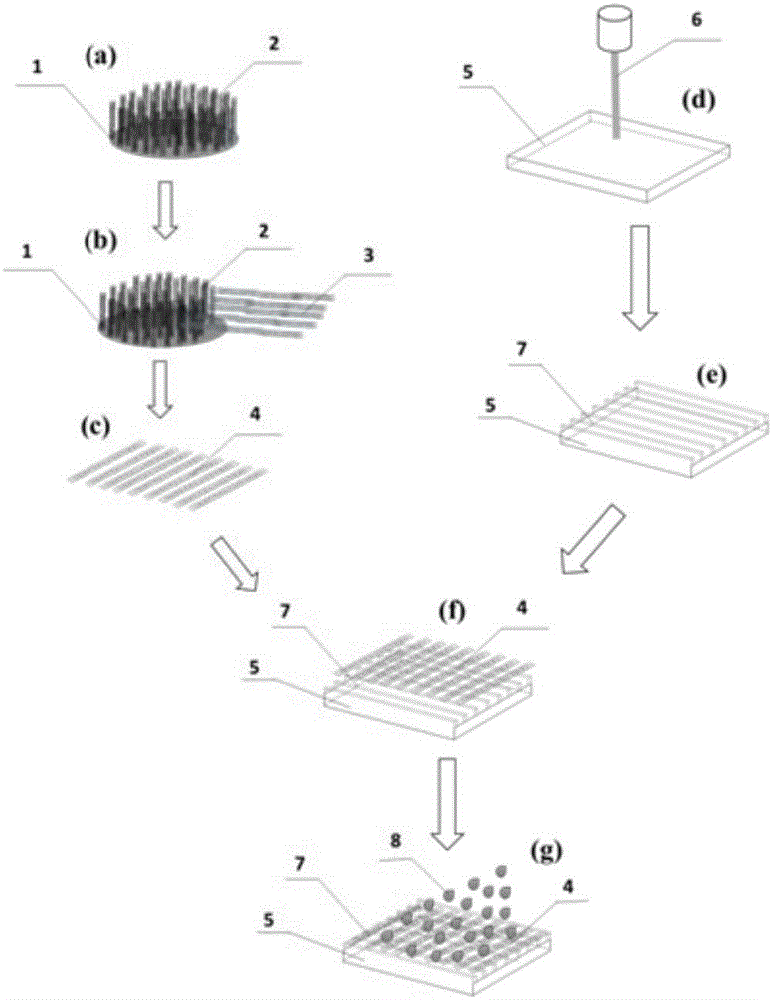

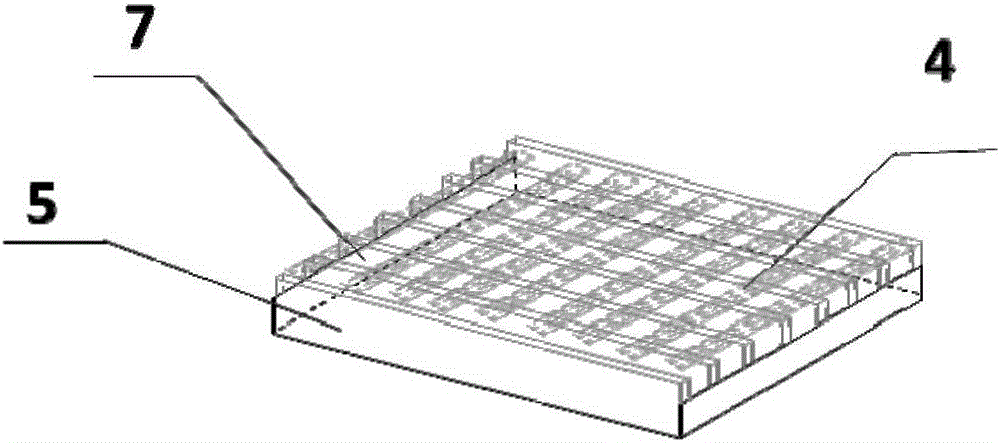

High-performance heat sink based on directional carbon nanotube thin film and fabrication method of heat sink

A carbon nanotube thin film and carbon nanotube array technology, which is applied in the research and development and application fields of thermal functional devices, can solve the problems of application limitation, large size, high safety performance requirements, etc. Thermal properties, effect of good contact properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

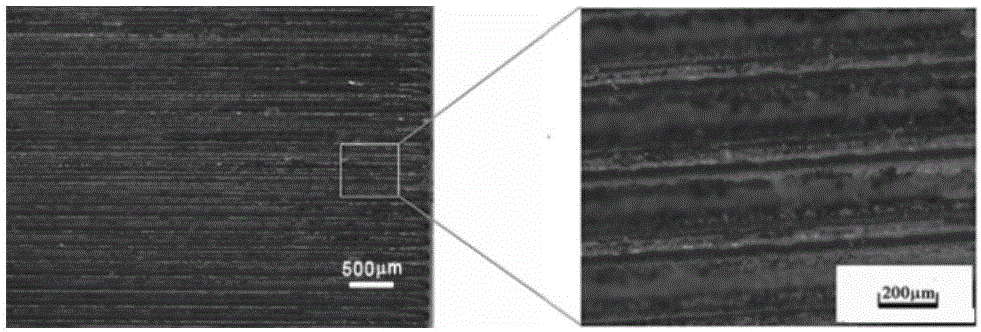

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: Heat dissipation performance test of a radiator based on an aligned carbon nanotube film

[0051] Figure 5 The comparison between the heat dissipation performance of the heat dissipation device of the present invention and the heat dissipation performance of common metal copper plates is shown. Under the same heating power (0.42W), the temperature variation and equilibrium temperature of the metal copper plate and the heat dissipation device of the present invention were measured respectively. Under the heating power, the equilibrium temperature of the heat dissipation device of the present invention is about 44.5°C, while the equilibrium temperature of the metal copper plate is about 63.5°C. This shows that the heat dissipation device of this invention has better heat dissipation performance. on the other hand, Figure 5 The temperature change curve in also shows that the cooling device in the present invention has a faster temperature stabilization s...

Embodiment 2

[0052] Embodiment 2: Natural convection heat dissipation performance measurement of a radiator based on an aligned carbon nanotube film

[0053] We can respectively calculate the size of the natural convection heat dissipation coefficient of the pure copper plate and the radiator of this invention according to formulas (1) and (2). Specific results such as Image 6 Shown, under 6 different heating power conditions, the natural convection heat dissipation coefficient size of radiator among the present invention is 37.4-44.2W / (m 2 .K), while the natural convection heat dissipation coefficient of metal copper plate is 19.8-27.9W / (m 2 .K). The natural convection cooling performance is improved by 58.4-88.9%. The result comparison shows that the heat dissipation device of this invention has significantly better natural convection heat dissipation performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com