Ground fine sand ceramsite concrete, preparation method thereof, light partition board and preparation method of light partition board

A technology of ceramsite concrete and lightweight partition wall panels, which is applied in the field of grinding fine sand ceramsite concrete, lightweight partition wall panels and their preparation, can solve the problems affecting the overall operation, management, construction and other costs, and the installation process time of wall panels. It can solve the problems of high length and overall floor load, so as to achieve the effect of excellent mechanical properties, small bulk density and low overall cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

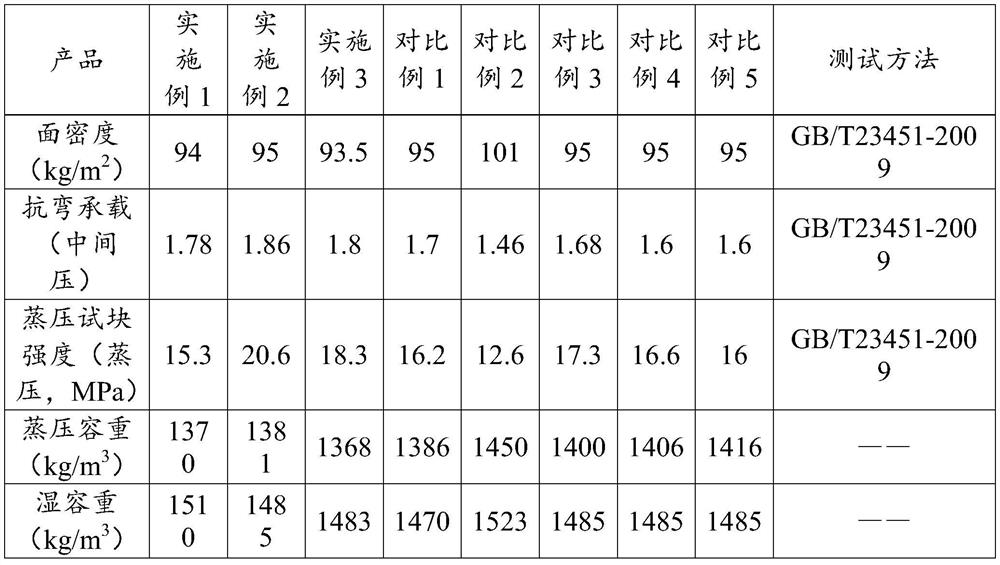

Examples

Embodiment 1~3

[0029] The embodiment of the ground fine sand ceramsite concrete, lightweight partition wall board and preparation method thereof of the present invention, the formula and proportioning ratio of the ground fine sand ceramsite concrete described in Examples 1 to 3 are shown in Table 1; wherein The molar ratios of the total calcium elements and the total silicon elements in the cement, fly ash and ground fine sand in the formulas of Examples 1 to 3 are respectively:

Embodiment 1

[0030] Embodiment 1 is (1.3:1);

Embodiment 2

[0031] Embodiment 2 is (1.2:1);

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com