Efficient normal pressure atomization generation device

A technology of generating device and normal pressure, which is applied to spray devices, atomized substances, liquid spray devices, etc., can solve the problems of low utilization rate of liquid medicine, waste, and decrease of heater surface temperature, so as to ensure the fogging rate and the production efficiency. The effect of fog volume, avoiding secondary condensation and preventing liquid accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

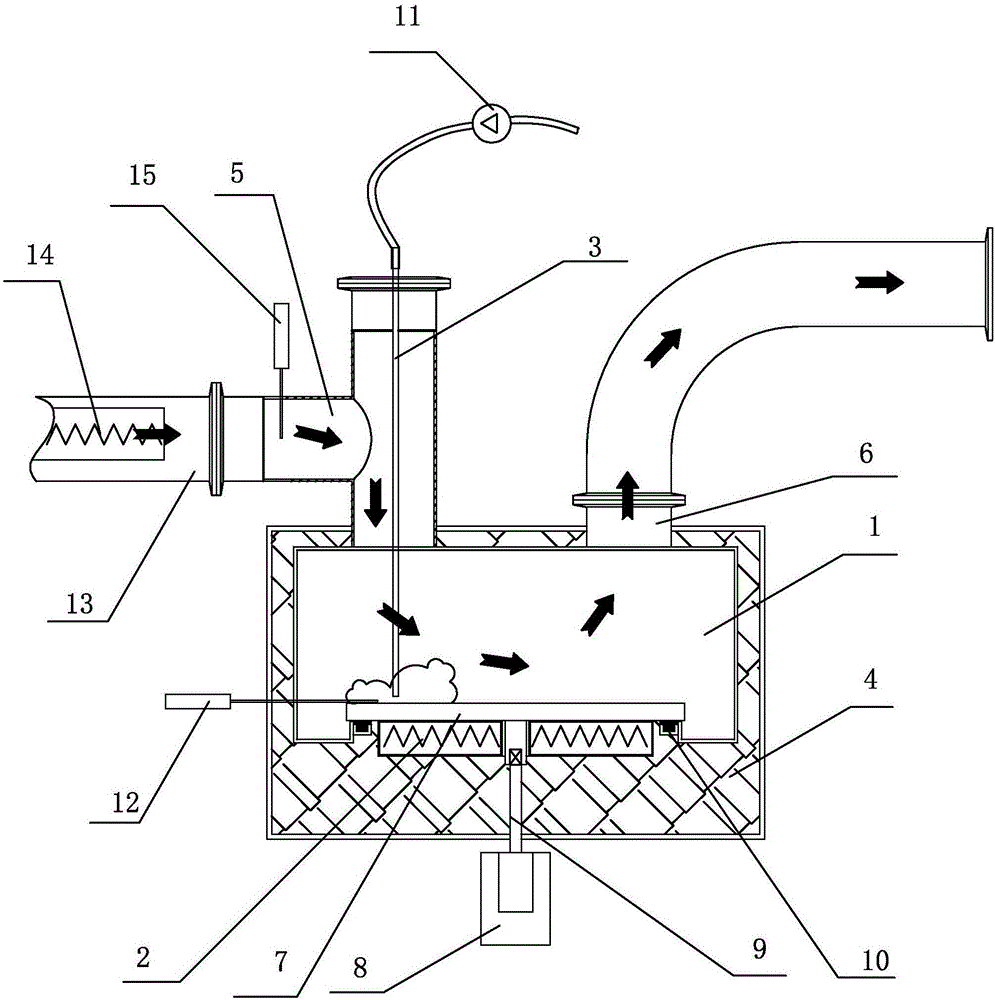

[0025] Embodiment one: see figure 1 As shown, a high-efficiency atmospheric pressure atomization generating device includes a mist-generating chamber 1, a heater 2, and a liquid medicine dropper 3. A heat-insulation layer 4 is provided between the mist-generating chamber 1 and the outside world. An air inlet 5 and an air outlet 6 are respectively provided on the warehouse 1, the heater 2 is located at the middle bottom of the misting chamber 1, and a rotating platform 7 is arranged above it, and a motor 8 is arranged at the bottom of the rotating platform 7. The output shaft 9 of the motor 8 passes through the heater 2 and is connected to the rotary platform 7. The output shaft 9 is provided with a thermal insulation layer (polytetrafluoroethylene or thermal insulation rock wool), and the rotary platform 7 is connected to the fogging chamber. 1 is provided with a sealing disc 10 to avoid leakage; the liquid medicine dropper 3 is located above the rotary platform 7, and the liq...

Embodiment 2

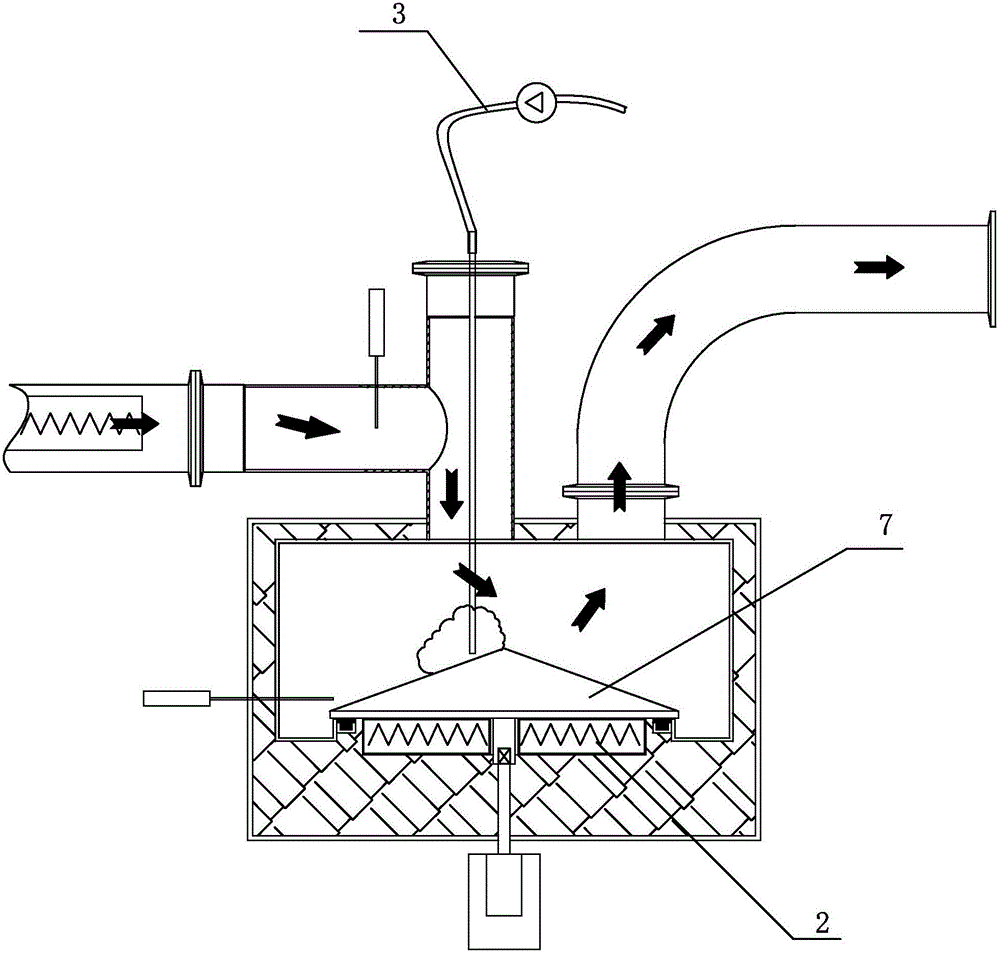

[0029] Embodiment two, see figure 2 As shown, a high-efficiency atmospheric pressure atomization generating device, in this embodiment, its structure is basically similar to that of Embodiment 1, the difference is that: the rotating platform 7 is a conical turntable with a raised middle, and the liquid medicine The liquid outlet of the dropper 3 is located above the top end of the conical turntable.

[0030] Such as figure 2 As shown, in this embodiment, the rotating platform 7 is a conical turntable, and the liquid medicine dropper 3 is located near the top of the cone, so that the liquid drips from the higher top, slides down along the slope of the cone, and It is continuously heated until it is vaporized. It can be seen that the conical turntable increases the heating area of the liquid. Although the conical turntable is not attached to the heater 2, the rotating platform 7 is heated by thermal radiation. However, the increased heating area can fully heat the liquid. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com