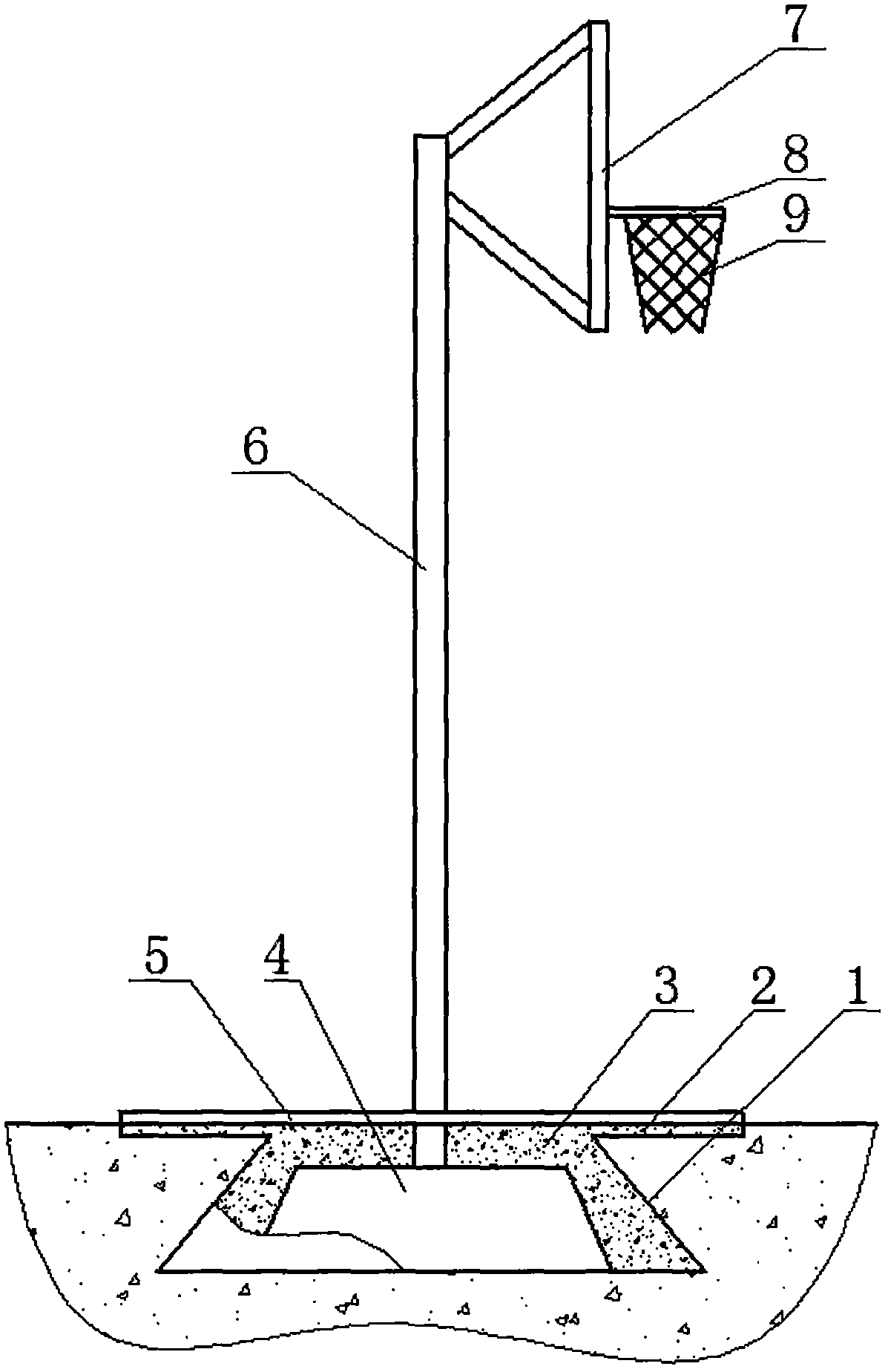

a basketball hoop

A basketball stand and backboard technology, applied in the field of basketball stands, can solve the problems of low stability, large floor space occupied by installation, and large size of the basketball stand, and achieve high stability, good corrosion resistance and impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: 80 parts of ordinary Portland cement, 6 parts of iron powder, 3 parts of sodium sulfite powder, 8 parts of fly ash, 3 parts of sulfurized acetone-formaldehyde polycondensate, 4 parts of beet honey, 1 part of corn starch molasses, rosin 3 parts of powder, 10 parts of alumina clinker, 0.5 parts of methyl ricinoleate, 1.5 parts of fatty alcohol sulfate, 5 parts of sodium alginate, 0.5 parts of B-aminoethyl stearamide, 4,4`-diamino 2 parts of stilbene-disulfonic acid, 0.8 parts of β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate.

Embodiment 2

[0025] Example 2: 90 parts of ordinary Portland cement, 8 parts of iron powder, 1 part of sodium sulfite powder, 15 parts of fly ash, 5 parts of sulfurized acetone-formaldehyde polycondensate, 1 part of beet honey, 2 parts of corn starch molasses, rosin 2 parts of powder, 3 parts of alumina clinker, 2 parts of methyl ricinoleate, 2.5 parts of fatty alcohol sulfate, 2 parts of sodium alginate, 0.7 parts of B-aminoethyl stearamide, 4,4`-diamino 2.5 parts of stilbene-disulfonic acid and 0.2 parts of β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid n-stearyl alcohol ester.

Embodiment 3

[0026] Example 3: 100 parts of ordinary Portland cement, 5 parts of iron powder, 2 parts of sodium sulfite powder, 20 parts of fly ash, 1 part of sulfurized acetone-formaldehyde polycondensate, 3 parts of beet honey, 4 parts of corn starch molasses, rosin 2 parts of powder, 7 parts of alumina clinker, 4 parts of methyl ricinoleate, 1 part of fatty alcohol sulfate, 3 parts of sodium alginate, 1 part of B-aminoethyl stearamide, 4,4`-diamino 1 part of stilbene-disulfonic acid and 0.4 part of β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate.

[0027] The concrete is prepared by the following method:

[0028] ① Take 40-50 parts of ordinary Portland cement, 5-8 parts of iron powder, 1-4 parts of beet honey, 2-5 parts of rosin powder, 3-10 parts of alumina clinker, 0.5- parts of methyl ricinoleate 4 parts, 0.5-1 part of B-aminoethyl hard amide, 1-2.5 parts of 4,4`-diaminostilbene-disulfonic acid, stirring and mixing, stirring temperature is -10-0℃, stirring time is 30 -40 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com