PDMS (polydimethylsiloxane) microfluidic chip structure and preparation method thereof

A microfluidic chip and microfluidic technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the problems of increasing the processing cost of microfluidic chips, and achieve uniform and controllable size. The effect of simple preparation method and simple forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

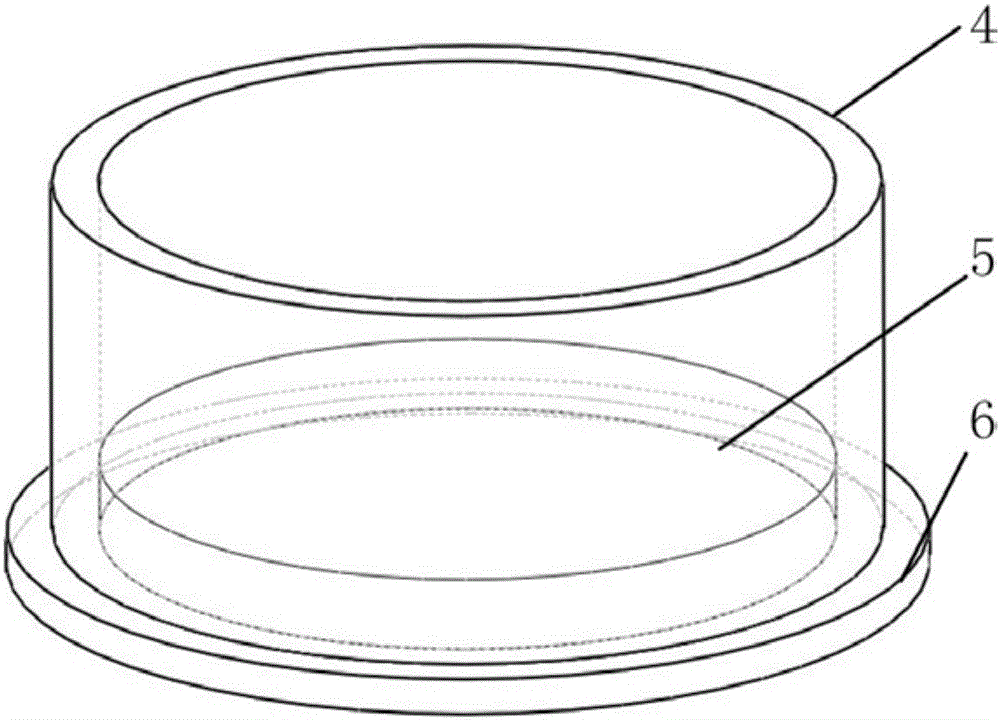

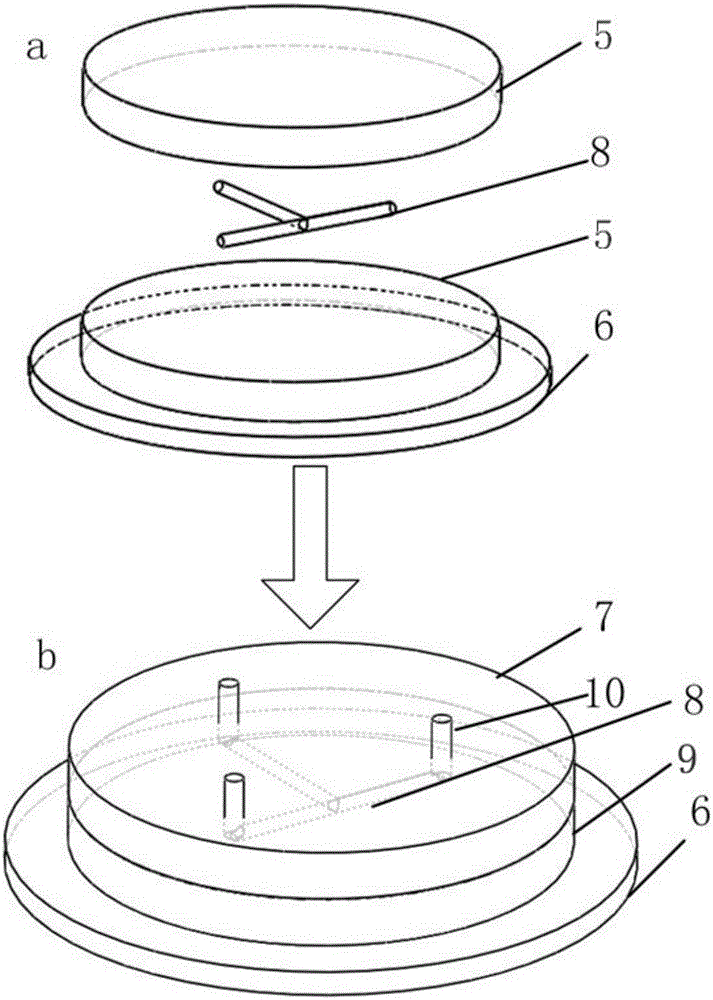

[0031] like image 3 As shown, the PDMS microfluidic chip of this embodiment includes an upper PDMS microfluidic chip 7 and a lower PDMS microfluidic chip 9, and a T-shaped glass is fixed between the upper PDMS microfluidic chip 7 and the lower PDMS microfluidic chip 9. The capillary microchannel 8 and the cross section of the glass capillary microchannel 8 are circular. Compared with the existing rectangular section, it has the advantages of small flow resistance, uniform and controllable size, simple forming process and good surface quality.

[0032] The preparation method of the PDMS microfluidic chip of the present embodiment comprises the following steps:

[0033] 1) Formation of circular cross-section glass microchannels:

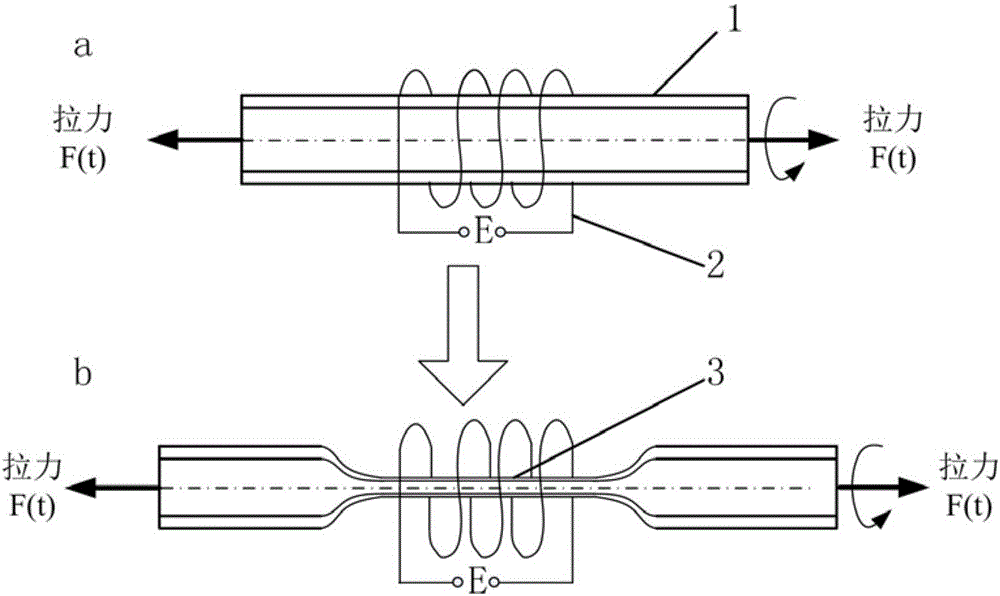

[0034] like figure 1 As shown, the two ends of the glass capillary 1 with an outer diameter of 1.0 mm, an inner diameter of 0.6 mm, and a length of 100 mm are clamped vertically on two fixtures. slide. The glass capillary 1 is made of borosilicate...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that a borosilicate glass capillary tube with an outer diameter of 5.0 mm, an inner diameter of 2.0 mm, and a length of 100 mm is drawn to form a glass microchannel, and a glass with a circular cross-section of 20 cm is obtained. Micro-channel, three glass micro-channels with a circular cross-section with a length of 20cm are placed on the surface of the lower PDMS prepolymer in a semi-cured state to form a Y-shaped glass capillary micro-channel according to the Y-shaped shape; the microfluidic chip The cross-section of the mold is replaced by a circle to a rectangle, and other structures and preparation steps refer to Example 1.

Embodiment 3

[0049] The difference between this embodiment and Embodiment 1 is that a quartz glass capillary with an outer diameter of 7.5 mm, an inner diameter of 5.0 mm, and a length of 200 mm is drawn to form a glass microchannel, and a glass microchannel with a circular cross-section of 30 cm is obtained. , three circular cross-section glass microchannels with a length of 30 cm are placed on the surface of the lower PDMS prepolymer in a semi-cured state according to a Y shape to form a Y-shaped glass capillary microchannel; the transverse direction of the microfluidic chip mold The cross-section is replaced by a triangle, and other structures and preparation steps refer to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com