Method for measuring content of ethylbenzene hydrogen peroxide

A technology for the content of ethylbenzene hydrogen peroxide, which is applied in the field of spectral analysis, can solve the problems of complex operation of the determination method, inability to realize on-line analysis, and inability to realize on-line analysis, and achieve the effects of avoiding moisture interference, good rigidity, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The material of the liquid pool used in Example 1 is: sodium chloride, potassium bromide and calcium fluoride, with a mass ratio of 1:8:3. Tablet pressing is carried out under the irradiation of an infrared lamp, and the infrared lamp is a special infrared baking lamp for an infrared spectrometer, and the power is 275W.

[0038] (1) Determination of the characteristic peak absorption band

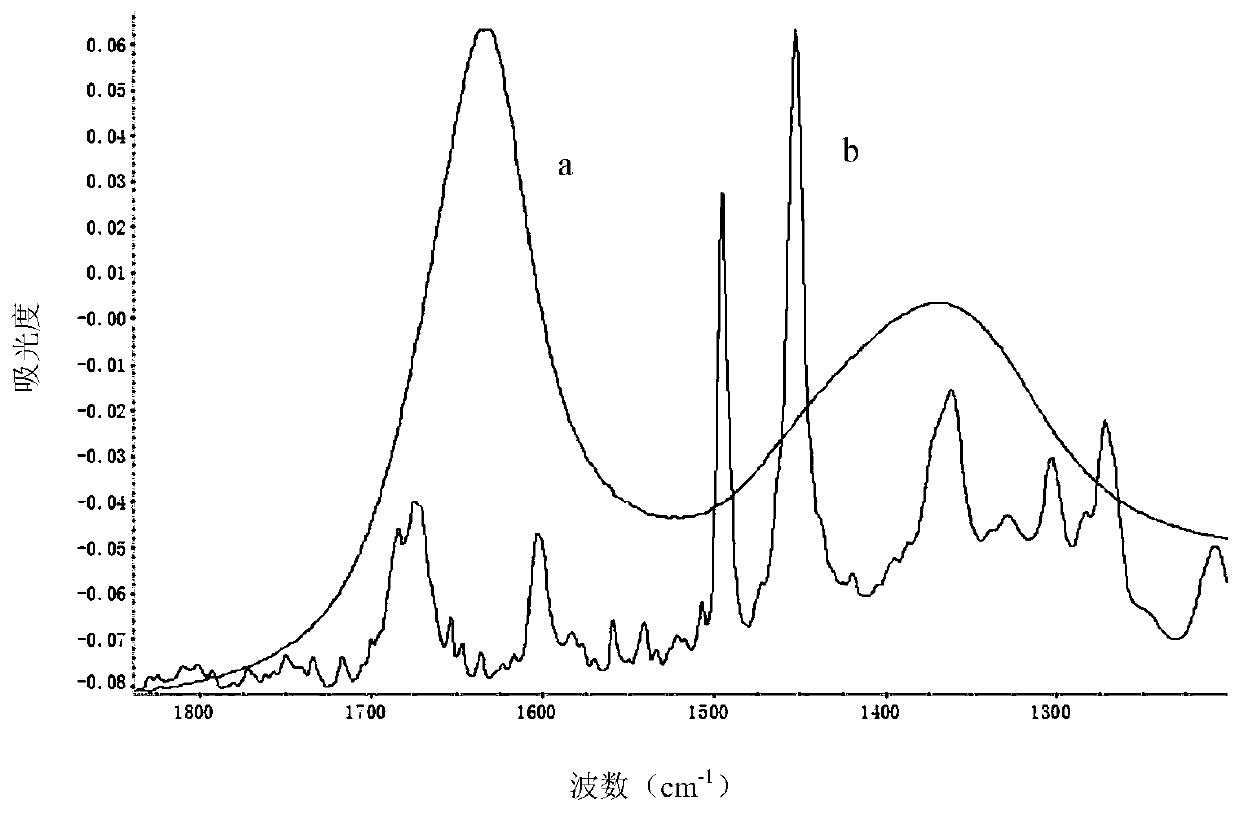

[0039] Select 30% hydrogen peroxide aqueous solution, inject it into the liquid pool with a disposable syringe, set the instrument parameters, and the infrared spectrum obtained from the test is as follows: figure 1 As shown in the a curve, it can be determined that the absorption band of the characteristic peak is 1230cm -1 ~1500cm -1 .

[0040] (2) Establishment of standard curve

[0041]Select 40 standard samples of known EBHP content (sample concentrations are: 4.59%, 7.87%, 33.83%, 7.53%, 34.05%, 33.97%, 31.85%, 8.00%, 8.21%, 8.19%, 8.26%, 6.25% %, 23.06%, 9.20%, 33.65%, 23...

Embodiment 2

[0053] Use the following materials to make a liquid pool: sodium chloride, potassium bromide, and calcium fluoride, with a mass ratio of 1:4:5. Measure according to the process of embodiment 1, after measuring 40 samples, the liquid pool still has no obvious change, and can continue to be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com