Flue gas pollutant treatment method based on wet plasma

A pollutant and plasma technology, which is applied in chemical instruments and methods, solid separation, electrostatic effect separation, etc., can solve the problems of limiting the industrial application of plasma purification technology, the complexity of plasma reaction and the difficulty of controlling the degree of discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

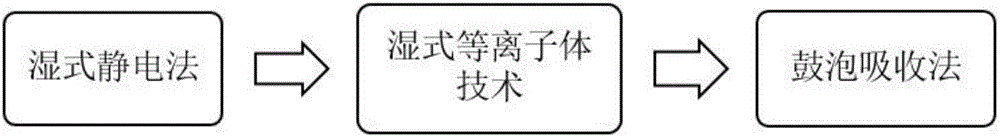

[0011] In one embodiment, the present invention discloses a method for treating flue gas pollutants based on wet plasma. The method includes the following steps:

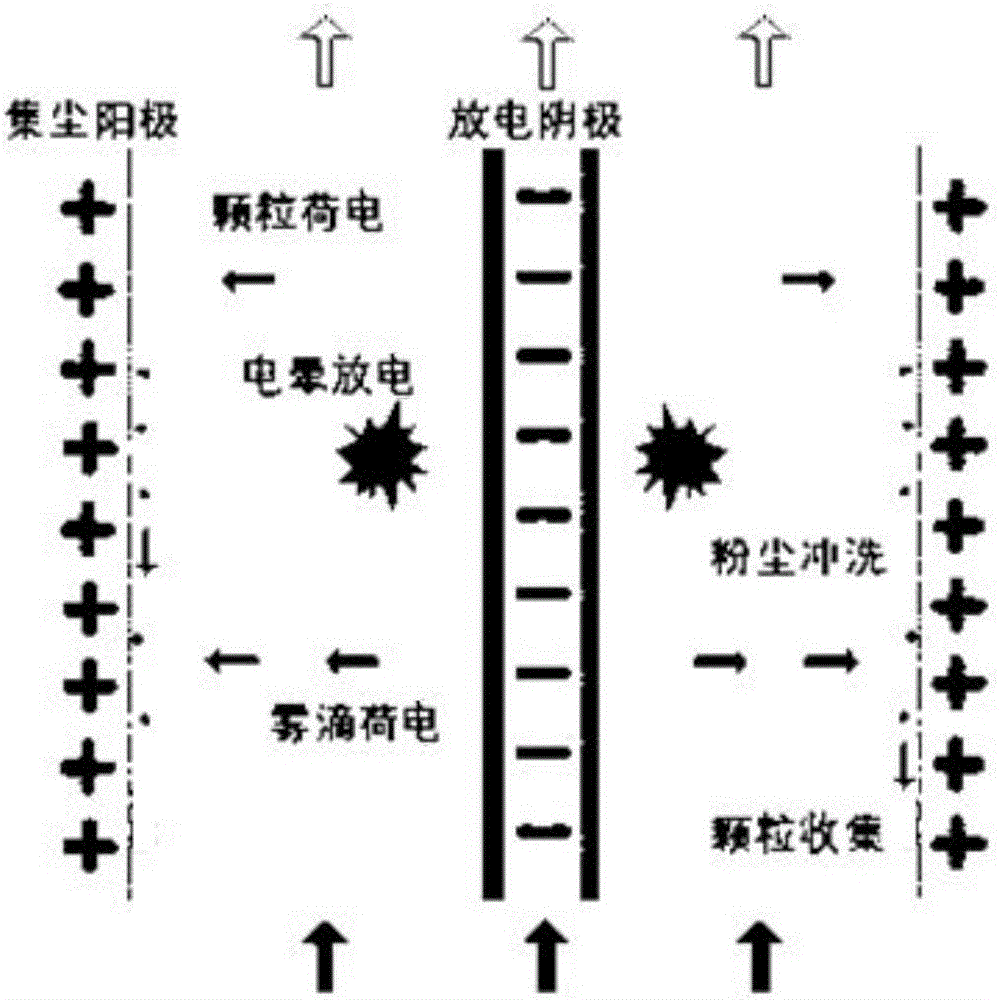

[0012] S100. Use wet electrostatic dust removal technology to adsorb and remove dust particles in flue gas;

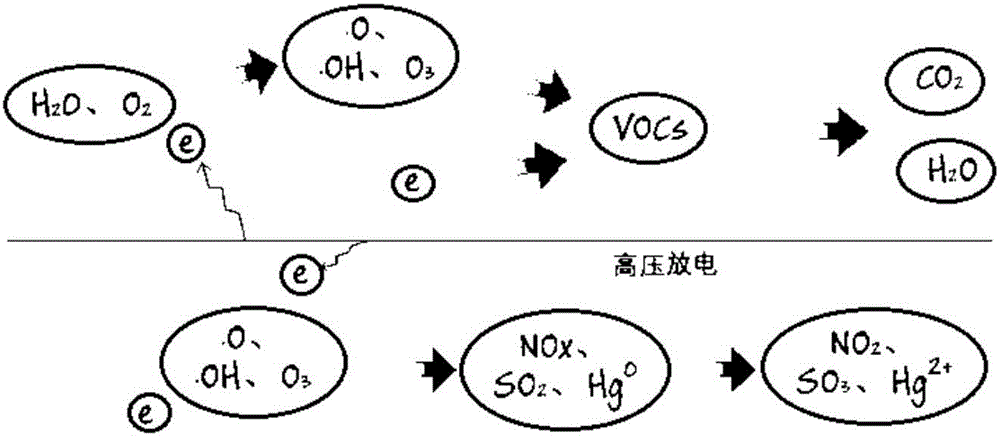

[0013] S200. Use wet plasma technology to oxidize and remove volatile organic compounds in flue gas and oxidize elemental mercury, sulfur dioxide and nitrogen oxides in flue gas;

[0014] S300, using a bubbling absorption method to absorb and remove residual pollutants in the flue gas after the treatment in step S200.

[0015] In this embodiment, as figure 1 As shown, a method for treating flue gas pollutants based on wet plasma is provided. The method first uses wet electrostatic technology to adsorb and remove dust particles in flue gas; and then uses wet plasma technology to treat flue gas The volatile organic compounds in the flue gas are oxidized and removed, and the elemental mercury, sulfur dioxide and nitrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com