Big-data-mining-based tool wear state prediction method under variable working condition

A technology for tool wear and prediction methods, applied in manufacturing tools, metal processing equipment, measuring/indicating equipment, etc., can solve problems such as poor accuracy, and achieve the effect of improving accuracy, improving prediction accuracy, and reducing prediction errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

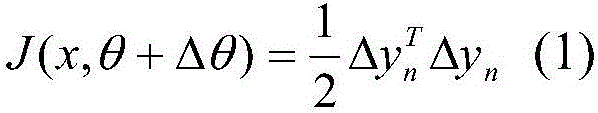

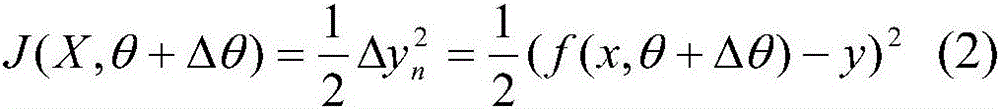

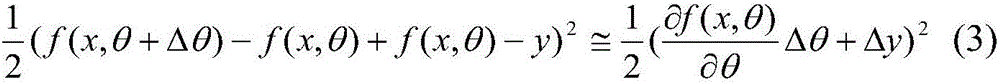

[0024] The specific steps of the tool wear state prediction method under variable working conditions based on big data mining in the present invention are as follows:

[0025] Firstly, the variable operating conditions are expressed in the form of operating condition vectors, and the changes in operating conditions are represented by the different values of the attributes in the vector. The working conditions that affect tool wear can be divided into four categories, the tool itself, the machine tool, the workpiece, the processing parameters, the representation of the working condition vector and the specific attributes included are as follows.

[0026] Machine tool condition vector L=(P,T q , f max ,n max ,P r ,D p ), where P represents the power of the machine tool, and T q Indicates the spindle torque, f max Indicates the maximum feed rate, n max Indicates the maximum speed P r Indicates the positioning accuracy of the machine tool, D p Indicates the dynamic para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com