Light curing preparation device of gradient material and light curing preparation method

A gradient material and preparation device technology, which is applied in the direction of manufacturing tools, additive processing, ceramic molding machines, etc., can solve the problems affecting the quality and reliability of biological functional gradient materials, uneven proportion control, and influence, so as to improve the utilization rate of materials , save materials, improve the effect of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

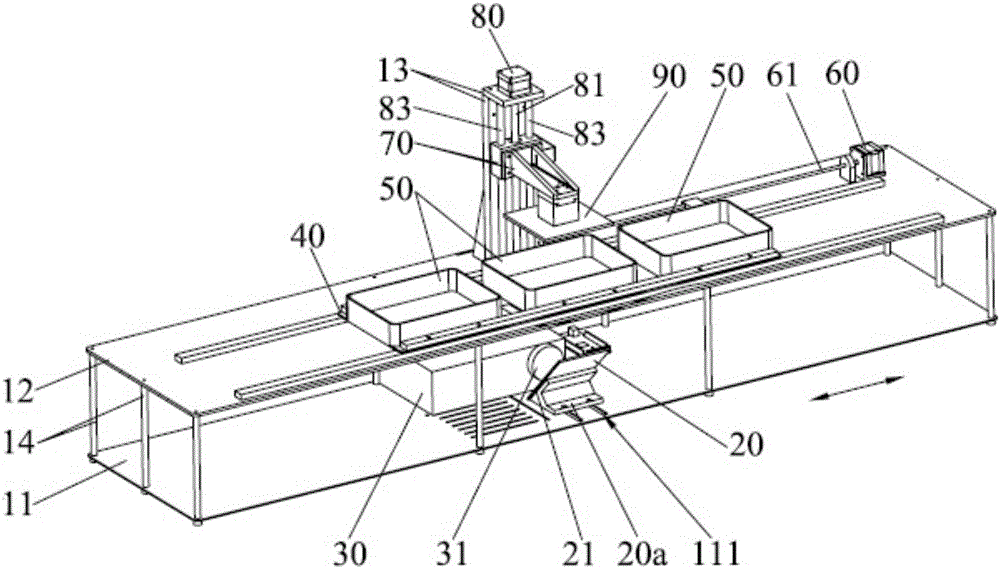

[0047] like figure 1As shown, the photocuring preparation device of the gradient material in this embodiment includes a frame, a reflector 20, a photocuring light source 30, a horizontal motion table 40, at least two transparent solution tanks 50, and a horizontal driver 60 , an up and down moving platform 70, an up and down driver 80, a forming platform 90 and a control system; the control system is used to model the gradient material, calculate the profile information of each layer in the modeling model, and use the profile information Generate the code required for photocuring molding, and control the horizontal driver, up and down driver and photocuring light source according to the code. The frame includes a bottom plate 11 , a top plate 12 , a vertical arm 13 and an intermediate support 14 . Specifically, in this embodiment, the bottom plate 11 and the top plate 12 are parallel to each other, but not limited thereto. The vertical arm 13 is installed on the top board 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com