Lacquer constant-temperature and constant-humidity storage device for lacquer paintings

A constant temperature and humidity storage device technology, applied in transportation and packaging, special packaging items, packaging under vacuum/special atmosphere, etc., can solve problems such as poor storage effect and affecting lacquer painting production, so as to save labor costs and reduce The effect of labor intensity and convenient handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

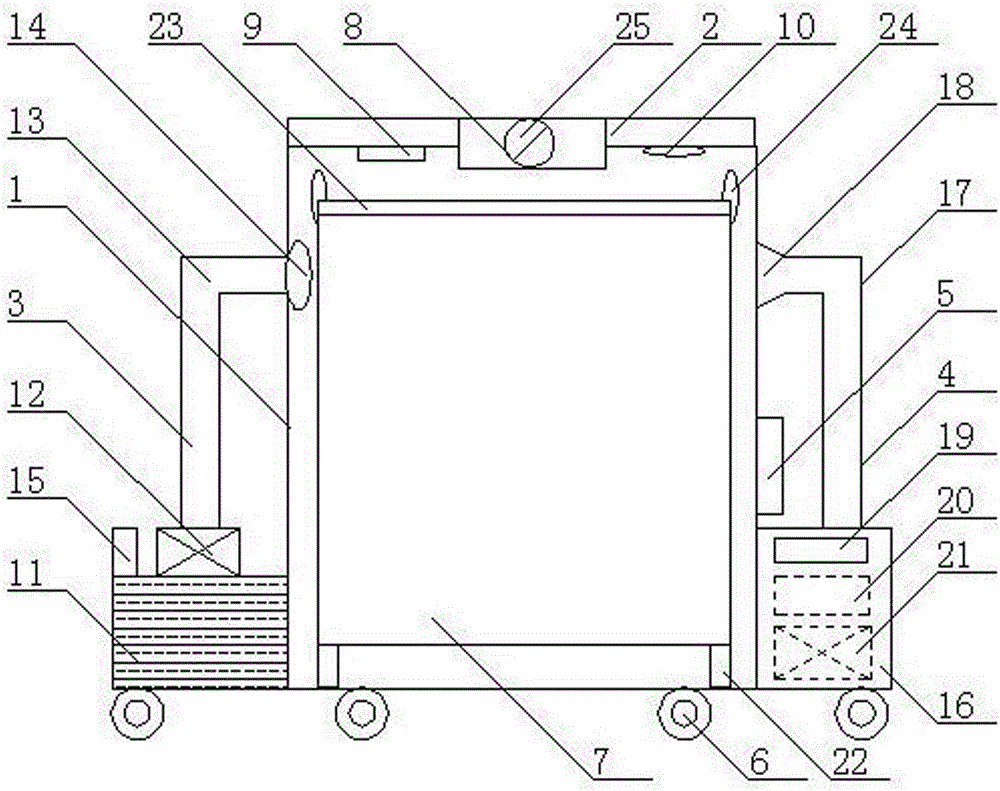

[0017] As shown in the figure, a lacquer constant temperature and humidity storage device for lacquer painting includes a fuselage 1, a top cover 2 is installed on the top of the fuselage 1, a constant humidity device 3 is installed on the left side of the fuselage 1, and the fuselage 1 is equipped with a constant humidity device 3. A constant temperature device 4 is installed on the right side of the body 1, a controller 5 is installed on the right side of the fuselage 1, a universal wheel 6 is installed on the left and right sides of the bottom of the fuselage 1, and a middle end device is installed inside the fuselage 1. Store casks7.

Embodiment 2

[0019] As shown in the figure, the middle end of the top cover 2 is equipped with a circulating wind area 8 , the left side of the bottom end of the top cover 2 is equipped with a temperature sensor 9 , and the right side of the bottom end of the top cover 2 is equipped with a humidity sensor 10 .

Embodiment 3

[0021] As shown in the figure, the constant humidity device 3 is composed of a water tank 11, a humidifier 12, a humidifying pipe 13, and a humidifying nozzle 14. A water pipe 15, a humidifier 12 is installed in the middle of the top of the water tank 11, and a universal wheel 6 is installed on the left side of the bottom of the water tank 11. The top of the humidifier 12 is connected to a humidifying nozzle 14 through a humidifying pipe 13, and the humidifying nozzle 14 is installed on the Fuselage 1 inner left upper end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com