Pre-oxidation method for preparation of large-tow carbon fiber

A large-tow carbon fiber and pre-oxidation technology, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, can solve the problems of less research on key technologies of large-tow carbon fiber processing, and achieve a good guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

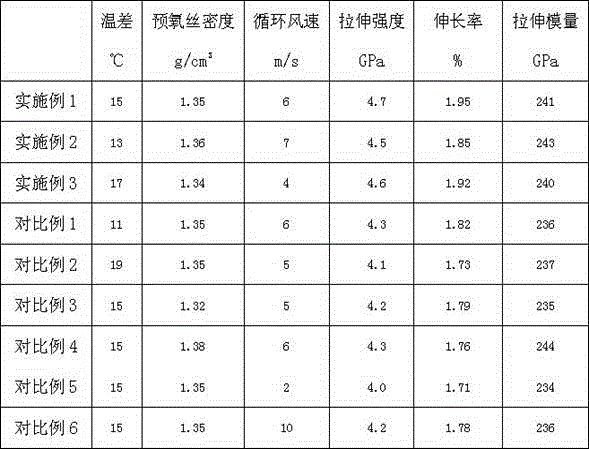

Embodiment 1

[0009] The PAN copolymer fiber (the tow is 24K, the copolymer composition (wt%) is: acrylonitrile (AN): Methyl acrylate (MA): itaconic acid (IA) = 96:2.0:2.0), in the air medium, using a three-stage pre-oxidation furnace at 225°C, 240°C, and 255°C, with a temperature gradient of 15°C, the oxidation furnace The wind speed of the internal circulation is 6m / s, the residence time is 80min, the draft ratio is 0%, and the density is 1.35g / cm 3 Under the protection of nitrogen, the pre-oxidized fiber is carbonized at a low temperature of 300-900°C for 3 minutes, and the draft ratio of +1% is applied; the draft ratio of -4% is applied at a temperature of 1000-1500°C, and the high temperature Carbonize for 3 minutes to obtain large tow carbon fibers. The prepared carbon fibers were glued and cured into strips with epoxy resin E44 / acetone / triethylenetetramine (10:15:1), and then the mechanical properties of the corresponding carbon fiber samples were tested according to the national st...

Embodiment 2

[0011] The 24KPAN copolymer fiber produced by Weihai Kaizhan Fiber Co., Ltd. is used, and it is treated in a three-stage pre-oxidation furnace at 230°C, 243°C, and 256°C. The temperature gradient is 13°C. The circulating wind speed in the oxidation furnace is 7m / s, and the residence time is 65min. The draw ratio is 1%, resulting in a density of 1.36g / cm 3 The preoxidized fiber, other process parameters and operation are the same as embodiment 1, obtains large tow carbon fiber, and the results are shown in Table 1.

Embodiment 3

[0013] The 24KPAN copolymer fiber produced by Weihai Kaizhan Fiber Co., Ltd. is used, and it is treated in a three-stage pre-oxidation furnace at 220°C, 237°C, and 254°C. The temperature gradient is 17°C. The circulating wind speed in the oxidation furnace is 4m / s, and the residence time is 75min. The draw ratio is 0%, resulting in a density of 1.34g / cm 3 The preoxidized fiber, other process parameters and operation are the same as embodiment 1, obtains large tow carbon fiber, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com