Structure-balancing movable environment-friendly floor and installation method thereof

A technology of balancing structure and installation method, applied in local raised floors, chemical instruments and methods, building structures, etc. It is convenient for maintenance and secondary paving use, increasing the dimensional stability of the product, and the effect of super anti-loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

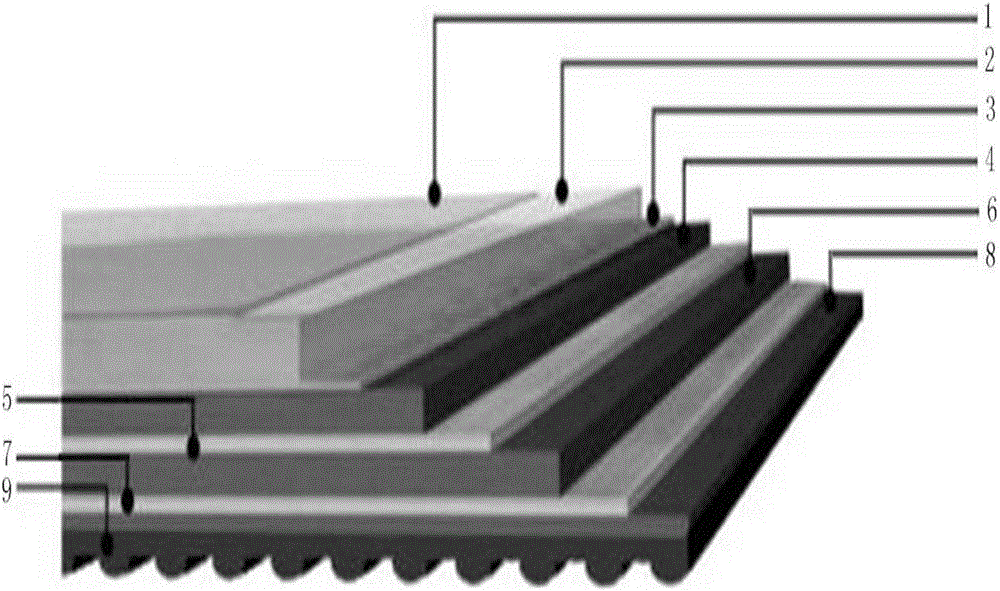

[0041] A movable environmental protection floor with a balanced structure, the thickness is 5mm, such as figure 1 As shown, it includes PUR coating 1, wear-resistant layer 2, printing layer 3, first PVC layer 4, first glass fiber layer 5, second PVC layer 6, second glass fiber layer 7, The third PVC layer 8, the non-slip bottom layer 9; the above 9-layer structure is hot-pressed and fused together by high-temperature hot-melt; the distance between the first glass fiber layer 5 and the wear-resistant layer 2 is the same as the distance between the second glass fiber layer 7 and the non-slip bottom layer 9 The distance between them is 1.5mm, and the double-layer glass fiber layer is symmetrically distributed in a network structure; the anti-slip bottom layer is a high-elastic rubber and plastic material printed with a tire pattern shape. The first PVC layer and the third PVC layer are symmetrically distributed, and the sum of the thicknesses of the first PVC layer, the second PV...

Embodiment 2

[0046] A movable environmental protection floor with a balanced structure, the thickness is 5.2mm, such as figure 1 As shown, it includes PUR coating 1, wear-resistant layer 2, printing layer 3, first PVC layer 4, first glass fiber layer 5, second PVC layer 6, second glass fiber layer 7, The third PVC layer 8, the non-slip bottom layer 9; the above 9-layer structure is hot-pressed and fused together by high-temperature hot-melt; the distance between the first glass fiber layer 5 and the wear-resistant layer 2 is the same as the distance between the second glass fiber layer 7 and the non-slip bottom layer 9 The distance between them is 1.55mm, and the double-layer glass fiber layer is symmetrically distributed in a network structure; the anti-slip bottom layer is a high-elastic rubber and plastic material printed with a tire pattern shape, which has a stable anti-slip function. The first PVC layer and the third PVC layer are symmetrically distributed, and the sum of the thickness...

Embodiment 3

[0050] A movable environmental protection floor with a balanced structure, with a thickness of 4.8mm, such as figure 1 As shown, it includes PUR coating 1, wear-resistant layer 2, printing layer 3, first PVC layer 4, first glass fiber layer 5, second PVC layer 6, second glass fiber layer 7, The third PVC layer 8, the non-slip bottom layer 9; the above 9-layer structure is hot-pressed and fused together by high-temperature hot-melt; the distance between the first glass fiber layer 5 and the wear-resistant layer 2 is the same as the distance between the second glass fiber layer 7 and the non-slip bottom layer 9 The distance between them is 1.45mm, and the double-layer glass fiber layer is symmetrically distributed in a network structure; the anti-slip bottom layer is a high-elastic rubber and plastic material printed with a tire pattern shape, which has a stable and anti-slip function. The first PVC layer and the third PVC layer are symmetrically distributed, and the sum of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com