A desulfurization and denitrification neutralization liquid PH value automatic adjusting and control system

A desulfurization and denitrification, control system technology, applied in the direction of control/regulation system, non-electric variable control, ratio control, etc., can solve the problems of unsafe limestone, violation of national standards, and low service life, so as to save labor management costs and reduce Excessive discharge accidents and the effect of saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

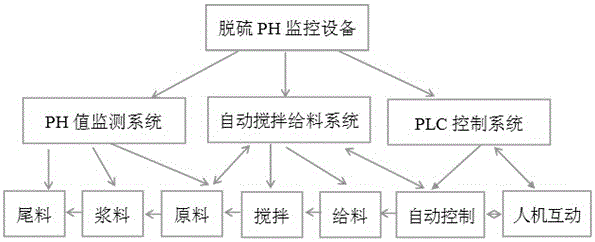

[0036] Embodiment 1: Example 1 is the enterprise desulfurization and denitrification neutralization liquid PH value automatic adjustment control system of the present invention: as figure 1 The shown enterprise desulfurization and denitrification neutralization liquid PH value automatic adjustment control system of the present invention is divided according to functions, including PH value monitoring system, automatic stirring and feeding system, and PLC control system. Among them, the functional level of the pH value monitoring system includes the pH value of the raw material, the pH value of the slurry, and the pH value of the tailing material; the functional level of the automatic stirring and feeding includes the feeding system and the stirring system; the PLC control includes the automatic control and human-computer interaction system.

Embodiment 2

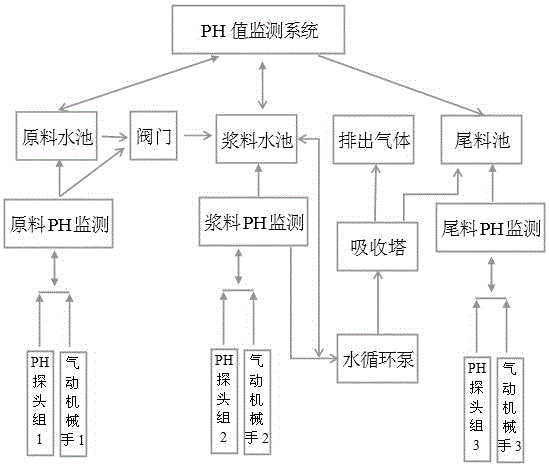

[0037] Embodiment 2: the pH value monitoring framework shown in the present invention is as figure 2 As shown, it includes the pH value of the raw material, the pH value of the slurry, the pH value of the tailing material, the water pump circulation system, and the structure of the pneumatic manipulator. The PH probe includes probe sensors and controllers. For example, the PH value sensor probe used by a power plant is Hach 6028, and its corresponding controller is SCD200. The PH value meter tests the PH value every 15 minutes, and the test value is determined by the line. It is connected to the control table, and the control table feeds back to the PLC according to the pH value. The water pump circulation system uses several water pumps to circulate the slurry to the absorption tower for desulfurization operation to reduce the sulfur content. In this case, the sulfur content should be lower than 50mg / m according to national regulations. 3 . Since the strong alkaline liquid...

Embodiment 3

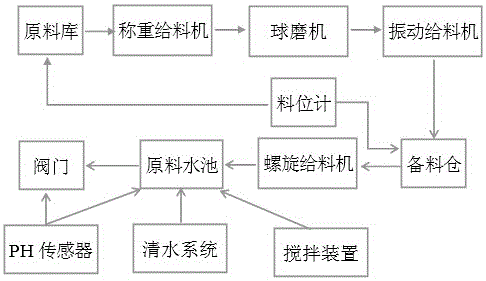

[0038] Embodiment 3: Example 3 is a schematic diagram of slurry feeding structure: as image 3 As shown, the limestone slurry preparation system provides qualified limestone absorbent slurry, which is the foundation of desulfurization. It is necessary to reasonably control the pH, density, liquid level, and mass fraction of limestone slurry to protect the feeding system and stirring system. In this example, the feeding system is the limestone slurry preparation system, which will supply the product to the limestone slurry tank at a certain flow rate. First, the signal is provided through the feedback of the material level sensor in the preparation bin, and the same value is provided by the limestone weighing feeder according to the feedback set value. Limestone with a high flow rate is ground to the ball mill continuously for several hours, and the qualified particle size is supplied to the preparation bin through the vibrating feeder, thus ensuring that there is always a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com