Pressureproof three-layer composite structured polypropylene microporous membrane

A polypropylene microporous film, three-layer structure technology, applied in the field of materials, can solve problems such as poor performance and poor battery production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

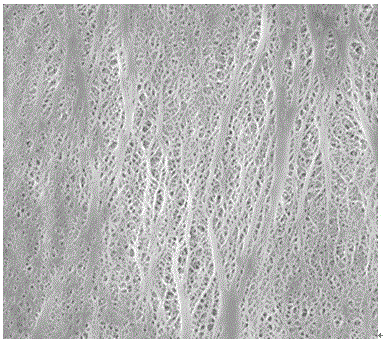

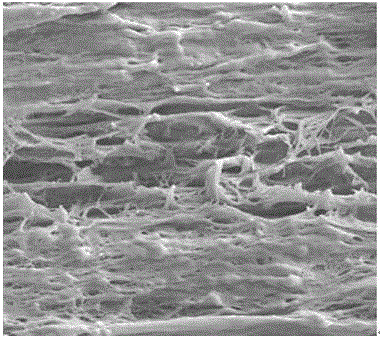

Image

Examples

Embodiment 1

[0025] 1) Add 0.5% by weight of N,N'-dicyclohexyl terephthalamide, 1% by weight of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester And 98.5% by weight of homopolypropylene mixing extruded granulation, obtain type I β crystal homopolypropylene, its β crystal content is 82%, melt index is 3.0g / 10min, crystallinity is 63%, fusing point is 165°C.

[0026] 2) 0.5% by weight of calcium pimelate, 1% by weight of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 98.5% by weight of homopolypropylene Mixing extrusion granulation to obtain type II β-crystal homopolypropylene with a β-crystal content of 80%, a melt index of 3.2g / 10min, a crystallinity of 60%, and a melting point of 165°C.

[0027]3) Use the above-mentioned type I β-crystal homopolypropylene as the raw material for the surface layer A and surface layer C, and use the above-mentioned type II β-crystal homopolypropylene as the raw material for the core l...

Embodiment 2

[0031] 1) Add 1.5% by weight of N,N'-dicyclohexyl naphthalene dicarboxamide, 1.5% by weight of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 97% by weight of homopolypropylene was mixed, extruded and granulated to obtain β-crystal homopolypropylene ①. The measured β-crystal content was 90%, the melt index was 5g / 10min, the degree of crystallinity was 68%, and the melting point was 166 ℃. 1.5% by weight of phthalimide, 1.5% by weight of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 97% by weight of homopolypropylene Mixing, extrusion and granulation yielded β-crystal homopolypropylene②, with a β-crystal content of 88%, a melt index of 4.5g / 10min, a crystallinity of 66%, and a melting point of 165°C.

[0032] 2) 1.5% by weight of suberic acid, 2% by weight of calcium carbonate, 1.5% by weight of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 95% The weight of ...

Embodiment 3

[0037] 1) 1.5% by weight of phthalimide, 1% by weight of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 97.5% by weight of homopolymer Polypropylene was mixed and extruded to obtain β-crystal homopolypropylene I. The measured β-crystal content was 82%, the melt index was 5g / 10min, the degree of crystallinity was 62%, and the melting point was 165°C. 2% by weight of WBG-II, 1% by weight of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 97% by weight of homopolypropylene are mixed and extruded Pelletizing to obtain β-crystal homopolypropylene II, the measured β-crystal content is 85%, the melt index is 4.8g / 10min, the degree of crystallinity is 63%, and the melting point is 163°C.

[0038] 2) Suberic acid of 2% by weight, calcium carbonate of 2% by weight, tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester of 1.5% by weight and 95% The weight of homopolypropylene was mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com