Method for large-area representation of graphite/silicon/amorphous carbon composite structure silicon-carbon cathode powder body

An amorphous carbon and composite structure technology, applied to structural parts, battery electrodes, electrical components, etc., can solve the problems of single characterization, inability to simultaneously characterize the distribution and structure of silicon-carbon anode components in a large area, and time-consuming problems, to achieve Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

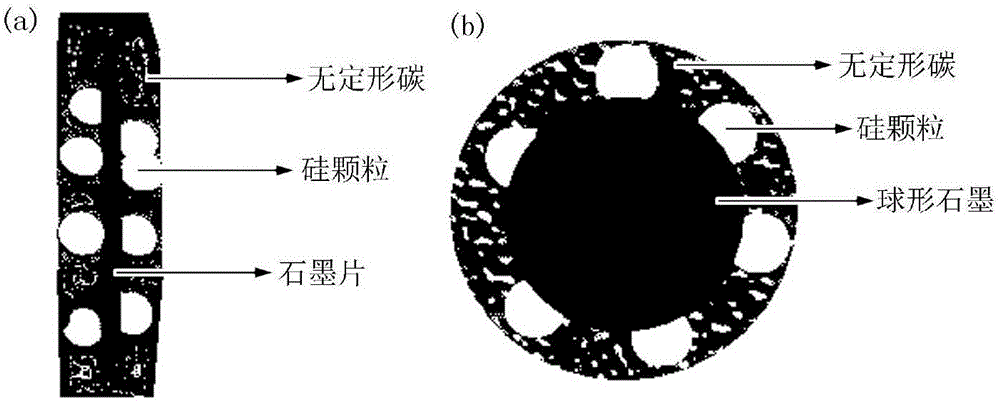

[0034]The graphite-silicon-amorphous carbon composite structure silicon-carbon negative electrode powder selected in this embodiment is formed by attaching silicon particles to the surface of spherical graphite and then coating a layer of amorphous carbon. Its structure is as follows figure 1 (b) shown.

[0035] (1) Pretreatment of silicon-carbon composite structure powder: Weigh 0.03g of graphite / silicon particles / amorphous carbon composite structure silicon-carbon anode powder, place it between two glass sheets with clean and flat surfaces and press firmly Compact it on the powder so that it does not fall off and the surface of the powder is smooth. The area of the powder after compaction is about 3.14 to 7.065 square centimeters.

[0036] (2) Acquisition of single Raman spectrum: Place the silicon-carbon anode powder material with a flat surface in step (1) on the sample test bench of the laser Raman instrument (HORRIBA, LabRAM HR Evol), select the test conditions to ensu...

Embodiment 2

[0044] The graphite-silicon-amorphous carbon composite structure silicon-carbon negative electrode powder formed by the silicon particles attached to the spherical graphite sheet and then coated with a layer of amorphous carbon in this embodiment has a structure such as figure 1 (a) shown.

[0045] (1) Pretreatment of silicon-carbon composite structure powder: First, weigh 0.06g of graphite sheet / silicon particle / amorphous carbon composite structure silicon-carbon negative electrode powder, and place it between two glass sheets with clean and flat surfaces And forcefully press it on the powder to compact it so that it does not fall off and the surface of the powder is smooth. The area of the powder after compaction is about 3.14 to 7.065 square centimeters.

[0046] (2) Acquisition of single Raman spectrum: Place the silicon-carbon anode powder material with a flat surface in step (1) on the sample test bench of the laser Raman instrument (HORRIBA, LabRAM HR Evol), select th...

Embodiment 3

[0051] According to the mass ratio of spherical graphite: silicon particle powder: amorphous carbon = 7:2:1, weigh a certain amount of spherical graphite, silicon particle powder, and amorphous carbon respectively and place them in a mortar, and mix them manually and mechanically for 5~ 10 minutes, then add ethanol and mix mechanically for 5-10 minutes, dry in an oven after mixing, take it out and then perform mechanical mixing for 5-10 minutes to ensure mixing uniformity, and obtain graphite-silicon-amorphous carbon mixed samples .

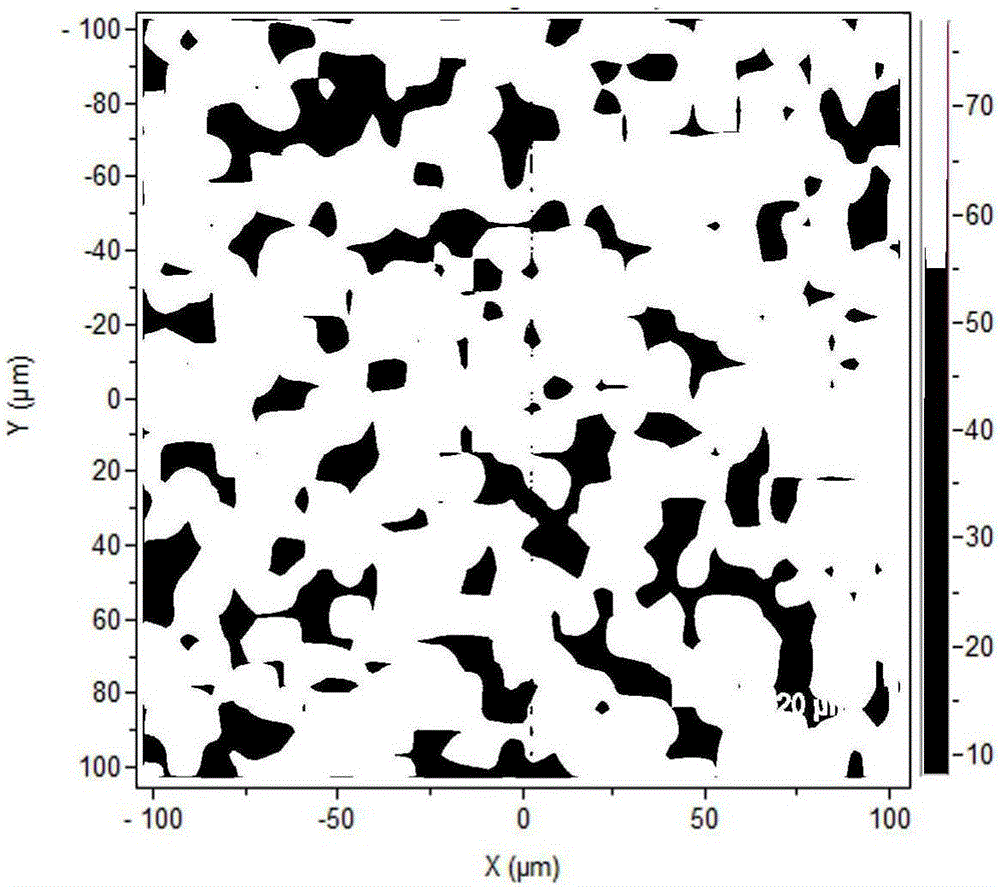

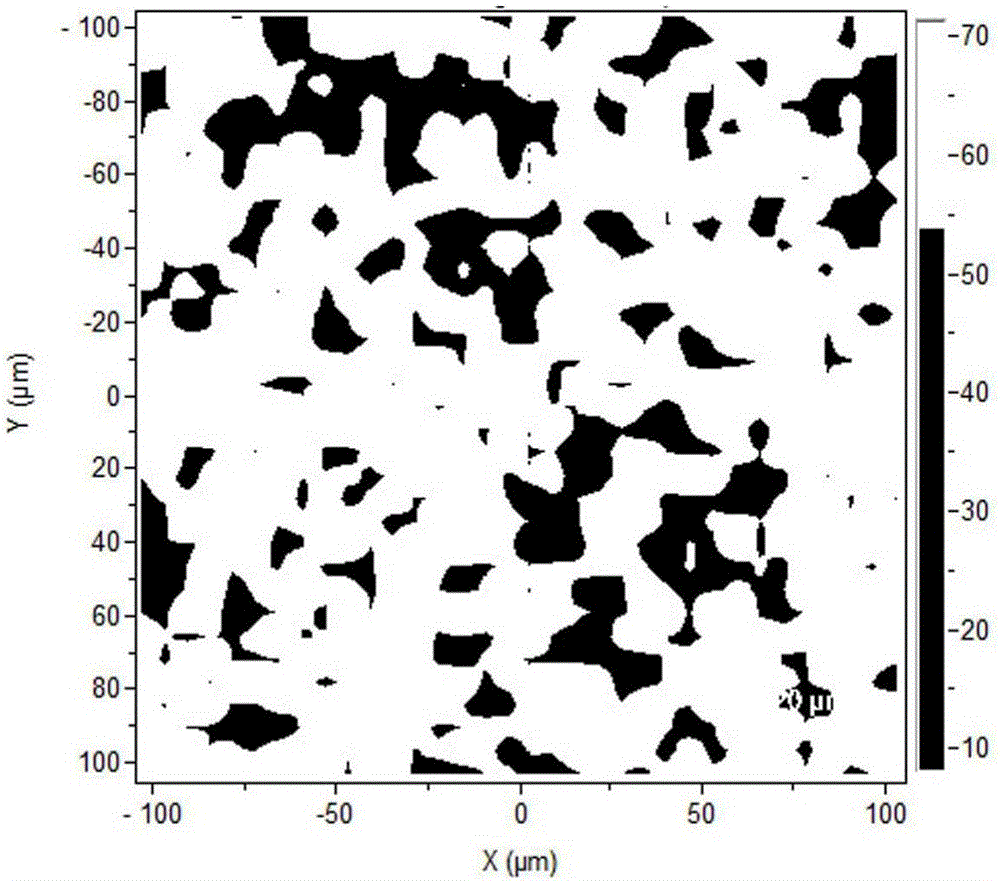

[0052] The graphite-silicon-amorphous carbon mixed sample prepared above is characterized by the treatment method of Example 1, the ratio of silicon peak, carbon D peak, carbon G peak, carbon D peak / carbon G peak, carbon G peak / carbon D The peak ratios of these five Raman imaging images are as Figure 6 , 7 As shown, the comparison can draw conclusions: first, the intensity distribution of Si peak, carbon D peak, and carbon G peak is very uneve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com