A battery management independent automatic cooling system

An automatic cooling and battery management technology, applied to secondary batteries, circuits, electrical components, etc., can solve the problems that heat exchange cannot be realized in the surrounding environment, and achieve the effects of low cost, increased current, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

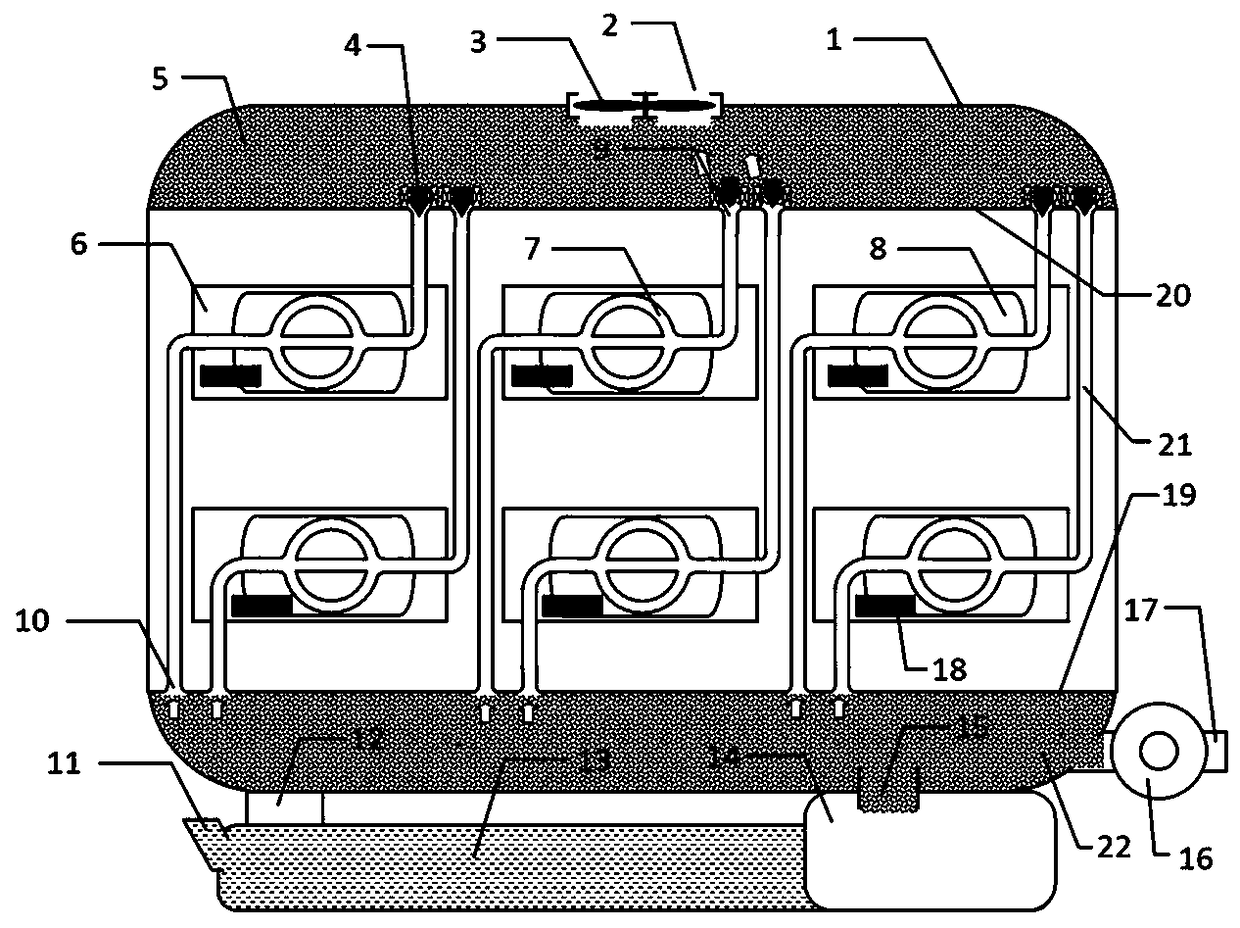

[0021] Example 2: The present invention consists of a combined power supply casing 1, an air exhaust port 2, an exhaust fan 3, a solenoid valve 4, an exhaust space 5, a battery cell 6, a heat-absorbing branch pipe 7, a heat-absorbing metal sheet 8, and a heat exhaust port 9. Water mist inlet 10, water injection port 11, water outlet 12, water storage tank 13, ultrasonic atomizer 14, water mist outlet 15, pressurized blower 16, fan air inlet 17, semiconductor thermistor 18 lower sealing plate 19. The upper sealing plate 20, the air pipe 21 and the water mist storage space 22 are composed; the top of the combined power supply shell 1 is provided with an air exhaust port 2, and an exhaust fan 3 is installed at the air exhaust port, and the combined power supply shell 1 is equipped with The upper sealing plate 20 and the lower sealing plate 19, all the battery cells 6 are placed in the upper and lower sealing plates, the upper sealing plate 20 is provided with a heat exhaust port 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com